Micro-lens (or micro-lens array) imaging detection plate

A microlens array, imaging detection technology, applied in the optical field, to achieve the effect of simple and fast detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

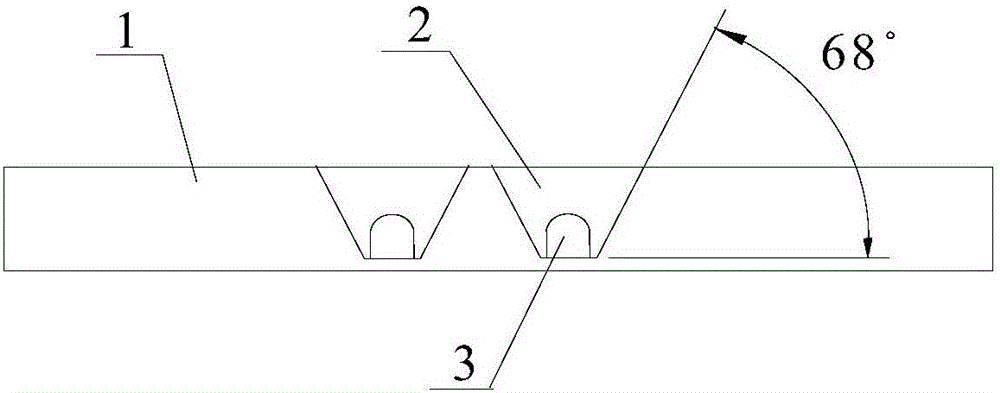

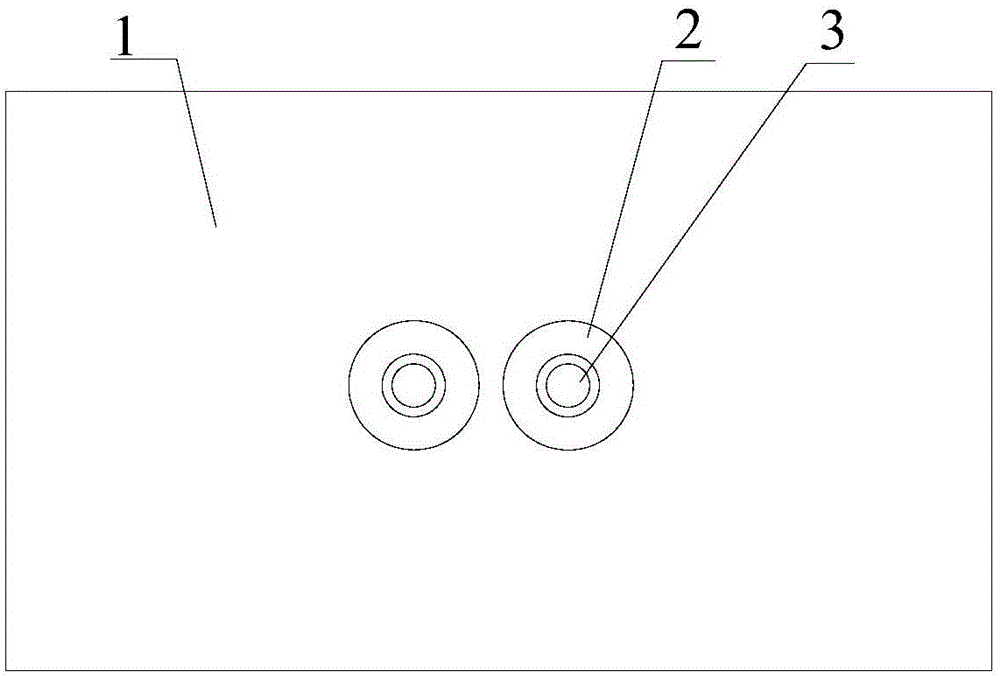

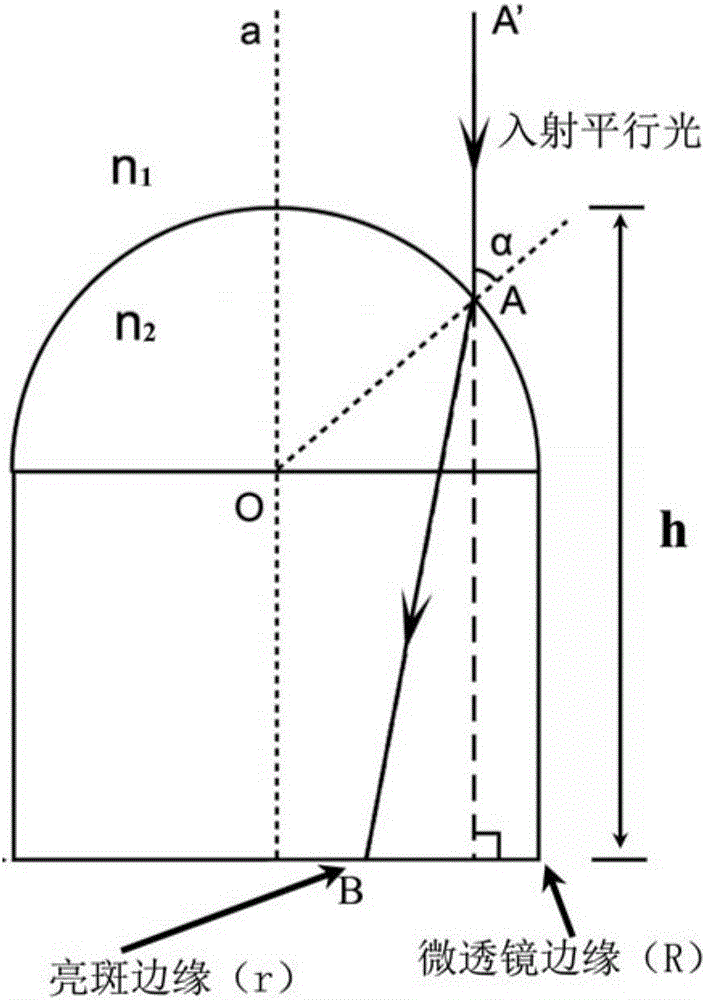

[0033] Such as Figure 1a and Figure 1b As shown, an imaging detection plate with two microlenses can detect two samples at the same time. The thickness of the transparent plate 1 of the entire imaging detection plate is 3.5 mm, and the thickness of the bottom of the trapezoidal concave hole 2 is 0.25 mm. Two cylindrical microlenses 3 in a trapezoidal concave hole 2 have a radius of 0.5 mm and a height of 1.0 mm; the two cylindrical microlenses 3 and the transparent plate 1 with two holes are integrally formed by precision injection molding of PMMA plexiglass material And made, its transparency > 90%, smoothness 40; use the multifunctional hydrophilic treatment agent DP-9993 that is composed of polyester-polyether-organic silicon terpolymer to carry out hydrophilic treatment (soaking at room temperature for 24 hours) .

[0034] When using this dual microlens imaging detection plate for solution refractive index detection, the solution to be measured is injected into the two ...

Embodiment 2

[0037] Different from embodiment 1, the cylindrical microlens 3 of the microlens imaging detection plate in embodiment 2 is a glass microlens, which is glued in the trapezoidal concave hole 2, and it is characterized in that the radius of the cylindrical microlens is 0.375 mm, height is 0.85 mm; transparent plate 1 is a PMMA plexiglass plate, thickness is 3 mm, the thickness at the bottom of the trapezoidal concave hole 2 is the same as the parameters in embodiment 1, and the process of other processing and detection imaging is the same as in embodiment 1.

Embodiment 3

[0039] Different from Embodiment 1, the microlens imaging detection plate in Embodiment 3 has 16 microlenses, which form a 4×4 array, such as Figure 3a and Figure 3b As shown, 16 cylindrical microlenses 3 are respectively placed in 16 trapezoidal concave holes 2, the thickness of the transparent plate 1 of the microlens array imaging detection plate is 3 millimeters, the radius of the cylindrical microlenses 3 is 0.5 millimeters, and the height is 1.5 millimeters , the cylindrical microlens 3 and the porous transparent plate 1 are made of PMMA plexiglass material through precision injection molding as a whole, with a transparency of >90%, a smoothness of 40, and a thickness of the bottom of the trapezoidal concave hole of 0.25 mm. Other processing and imaging detection processes are the same as in Example 1, except that the detection board can detect 16 samples at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com