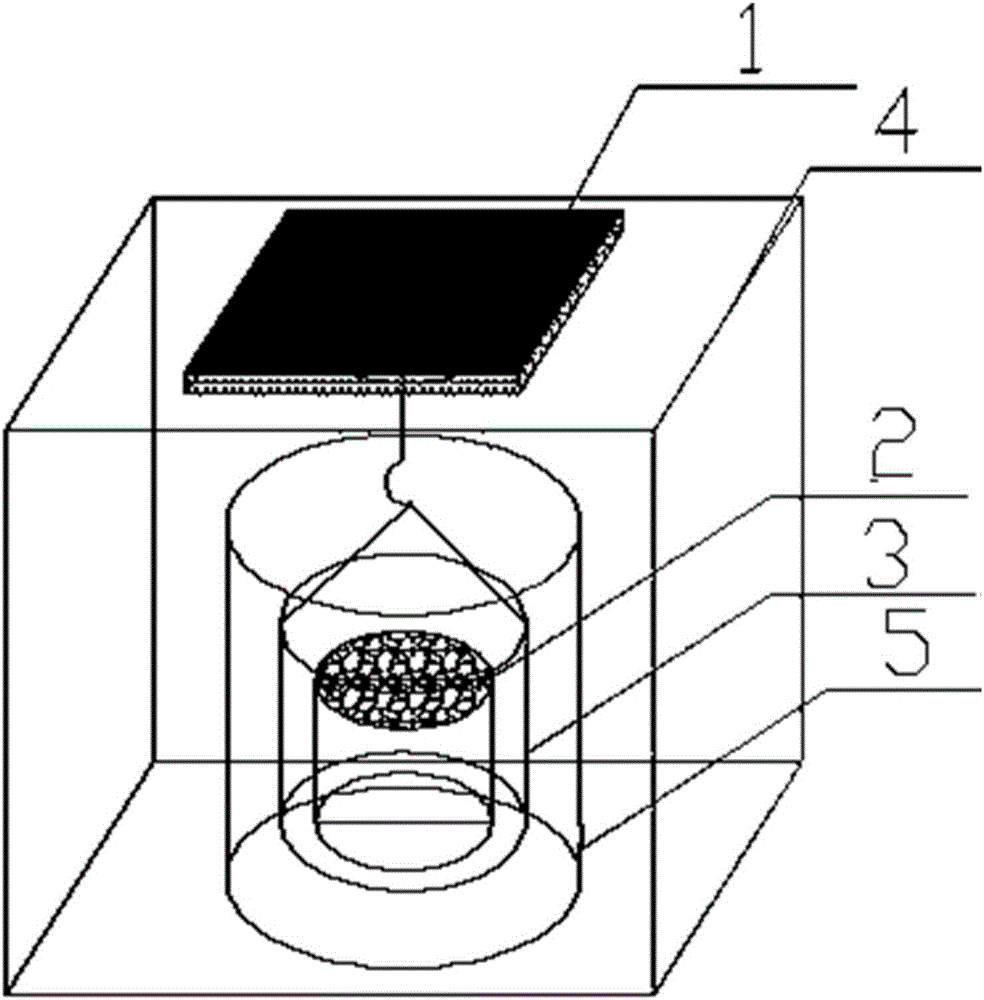

Device and method for determining gross volume density of bituminous mixture through wax sealing

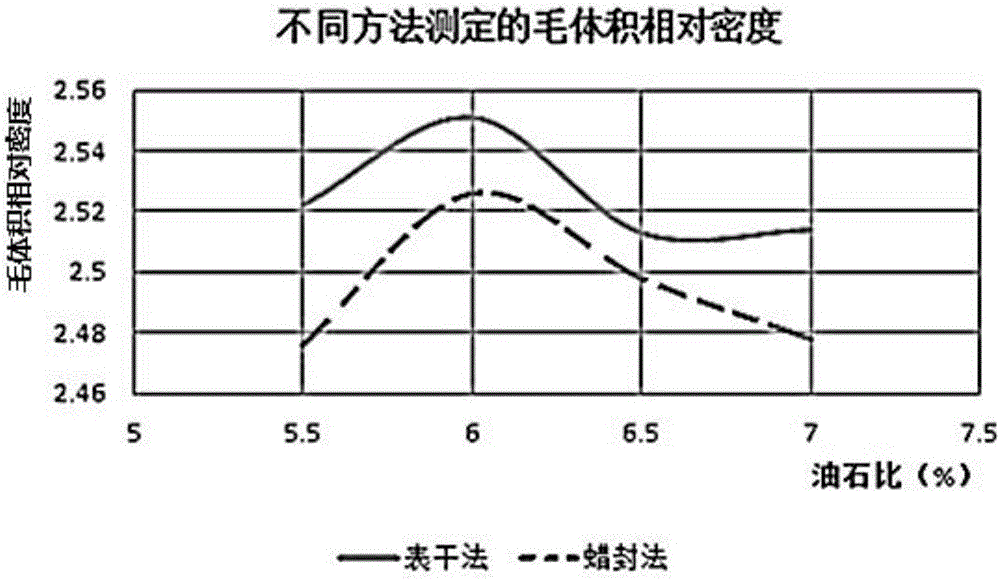

A technology of asphalt mixture and bulk density, which is applied in the directions of measuring devices, specific gravity measurement, and analysis materials, etc., can solve the cumbersome test of the bulk density of asphalt mixture specimens, affect the mix design of asphalt mixture, and dry saturated surface The state is difficult to form and other problems, and the test process is fast, the result is real and reliable, and the effect of convenient implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

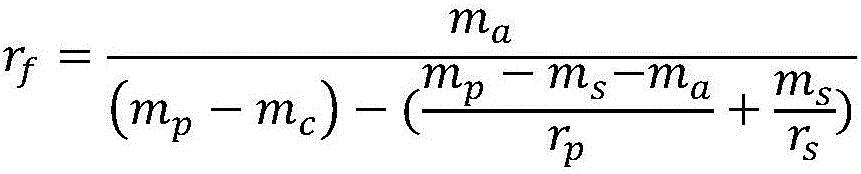

Method used

Image

Examples

Embodiment 1

[0065] Use an electronic balance with a measuring range of 4Kg and an induction capacity of 0.01g to weigh the air mass m of the dry test piece a =1207.7g, prepare a sufficient amount of standard sand and place it in the sand tray, place the sand tray on another electronic balance and set the balance reading to zero;

[0066] Melt the paraffin wax to about 55°C, and heat the dropper to the corresponding temperature at the same time, take a certain amount of standard sand from the sand tray and penetrate it into the surface of the test piece, use the dropper to absorb the wax solution and quickly drop it onto the asphalt For the surface of the mixture specimen, after dripping one side of the specimen with a dropper, dip a little wax solution from the wax solution with a hair body and brush and level the asphalt mixture specimen;

[0067] Dry and cool the wax-sealed test piece at room temperature, then dip a small amount of wax solution with a brush, carefully apply it to the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com