Heat pump drying method for marinated betel nuts

A technology of heat pump drying and drying method, applied in the direction of dryer, heat pump, drying gas arrangement of static materials, etc., can solve the problems of reducing the yield of betel nut, low drying efficiency, large influence of human factors, etc., to achieve secondary drying and The effect of continuous production, improving production efficiency and shortening drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

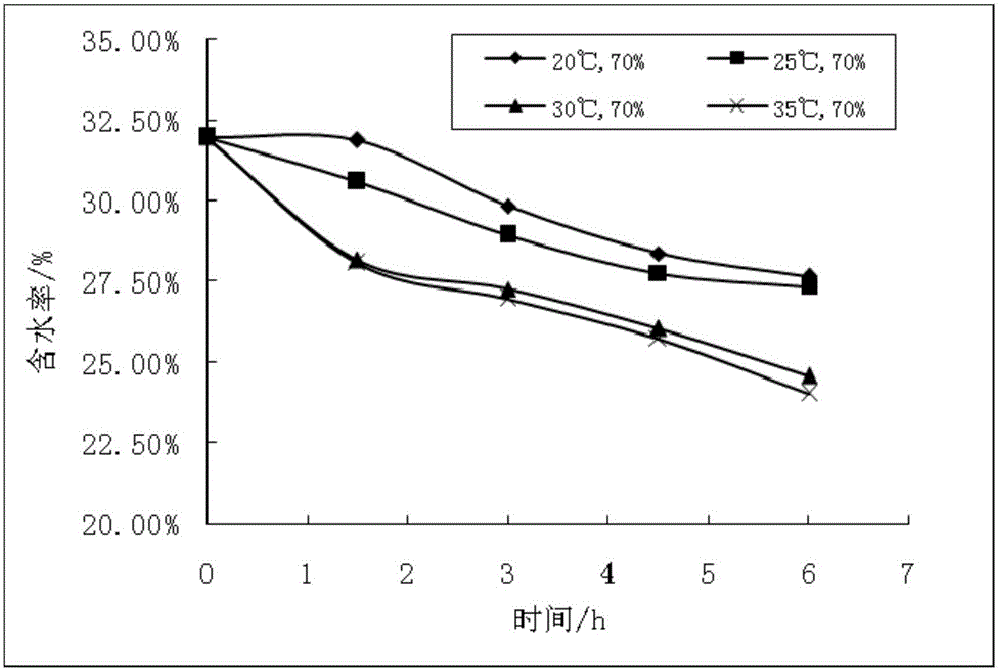

[0039] Such as Figure 5 Shown is the moisture content curve of the high-temperature, low-humidity drying-normal temperature, high-humidity slow recovery cycle multi-stage drying process. From Table 1, it can be seen that during the process of slowing down at room temperature and high humidity, the fluid brine with higher moisture in the material penetrates into the oil betel nut with lower moisture, so that the moisture gradient gap between the two gradually narrows, and the brine gradually becomes viscous, and then enters a short-term high temperature. In low-humidity drying, the brine betel nut evaporates part of the water accordingly, but because the surface area of the oil betel nut is greater than the evaporation surface area of the brine, the water in the brine will continue to penetrate into the oil betel nut when it enters the slow recovery stage again, and at the same time, it will also transfer water to the dry brine surface. The two strands of water traction re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com