Engineering vehicle adopting exhaust turbocharging auxiliary device

A technology for exhaust gas turbines and engineering vehicles, which is applied in engine control, machine/engine, internal combustion piston engines, etc., and can solve the problems that the intake turbo pumping effect will not weaken rapidly, the gas is not fully utilized, and the throttle assembly is damaged. , to achieve the effects of reducing air pressure, reducing turbine time lag, and reducing pump air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

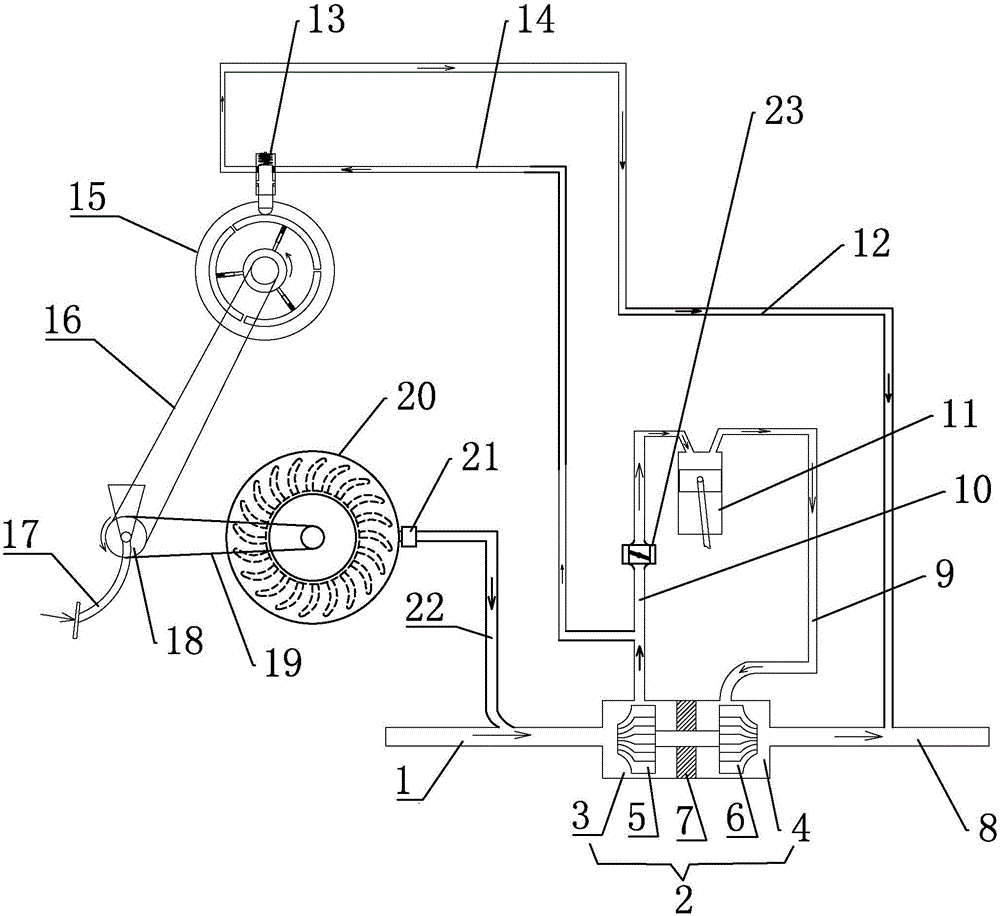

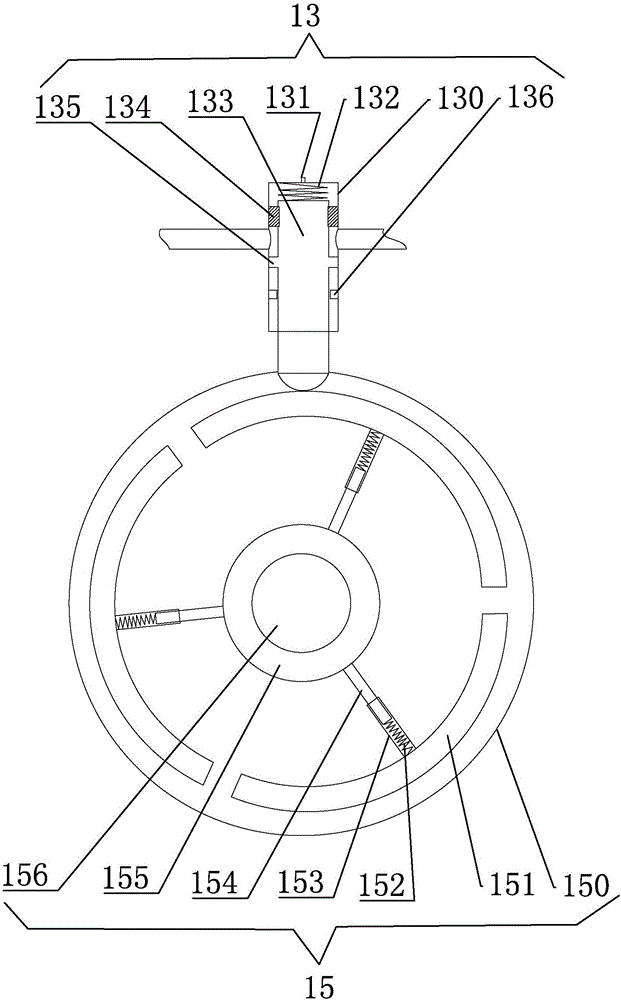

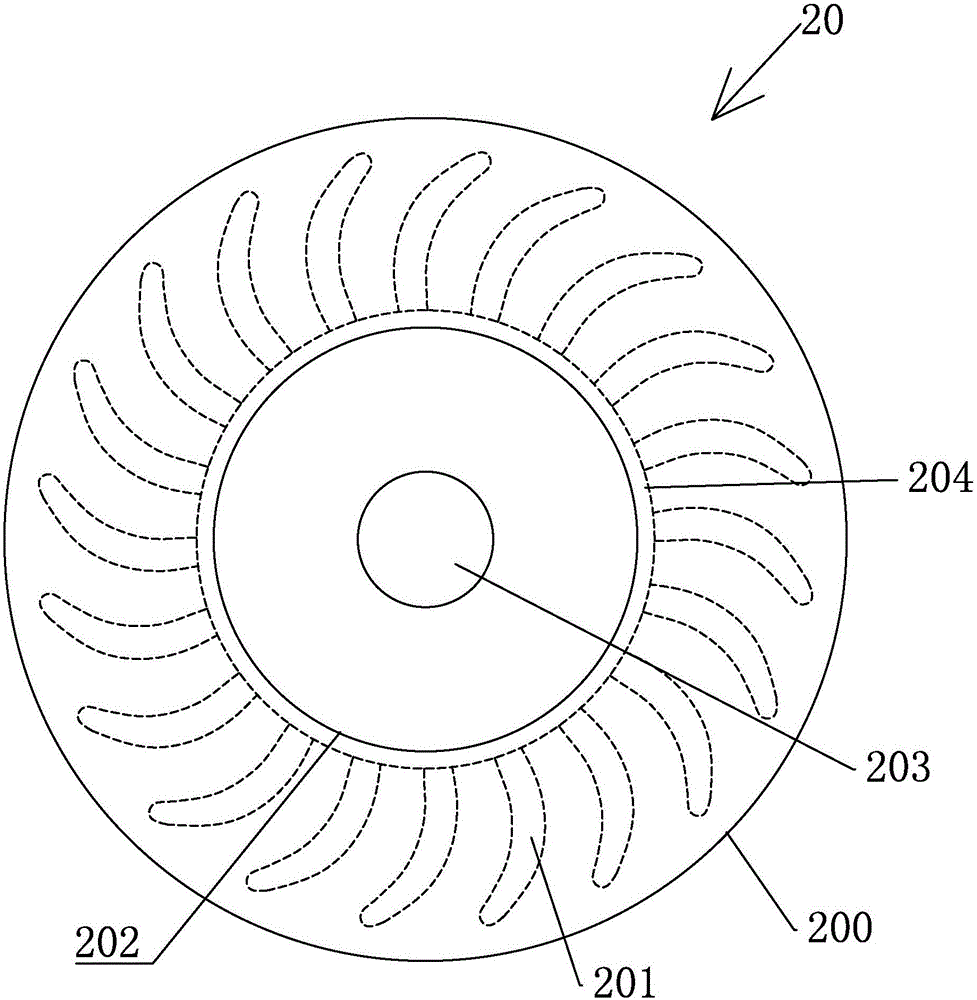

[0032] attached Figure 1-6 The components corresponding to the reference signs in the figure are: front intake pipe 1, exhaust gas turbocharger 2, intake cavity 3, exhaust cavity 4, intake turbine 5, exhaust turbine 6, partition 7, exhaust Pipe 8, exhaust manifold 9, rear intake pipe 10, cylinder block 11, gas inlet pipe 12, gas valve 13, gas outlet pipe 14, centrifugal controller 15, belt one 16, accelerator pedal 17, driving wheel 18, Belt two 19, air blower 20, one-way valve 21, air supply pipe 22, throttle valve 23; valve housing 130, air vent 131, control spring 132, valve core 133, sealing ring 134, limit block 135, positioning block 136; Housing 150, sector block 151, connecting spring 152, sliding sleeve 153, sliding rod 154, large runner 155, small runner 156; casing 200, blade 201, air inlet 202, driven wheel 203, impeller 204, one-way clutch One 157, one-way clutch two 205; throttle housing 231, throttle shaft 232, flap 233.

[0033]The exhaust gas turbocharger 2...

Embodiment 2

[0046] On the basis of Embodiment 1, there are the following modifications in this embodiment:

[0047] As another implementation of the flow control device, the flow control device includes an electric gas valve, and the gas inlet and outlet ports of the electric gas valve are respectively connected to the adjacent ends of the gas inlet pipe 12 and the gas outlet pipe 14; the electric gas valve is provided by the engineer. The vehicle controller controls its opening, and the engineering vehicle controller (that is, the central processing unit that controls the engineering vehicle) detects the state of the accelerator pedal 17 through a sensor, and then controls the opening of the electric gas valve; When the pedal 17 is changed from the depressed state to the relaxed state, the electric gas valve is controlled to guide an appropriate amount of gas from the gas outlet pipe 14 into the gas introduction pipe 12 . The greater the clockwise speed when the accelerator pedal 17 is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com