Steam turbine and organic Rankine cycle fluid turbine dual-drive combined electricity generation or mechanical working equipment

A Rankine cycle, dual-drive technology, applied to steam engine devices, machines/engines, mechanical equipment, etc., can solve the problem that the heat source cannot be fully utilized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

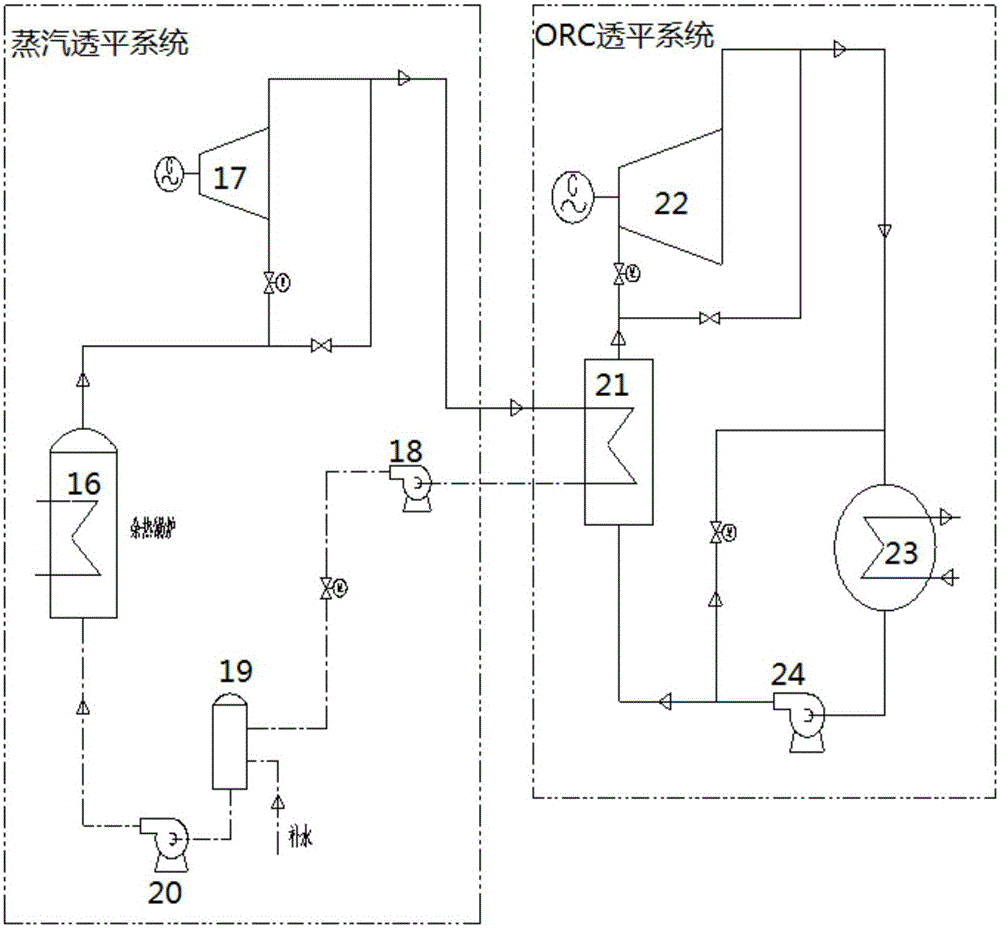

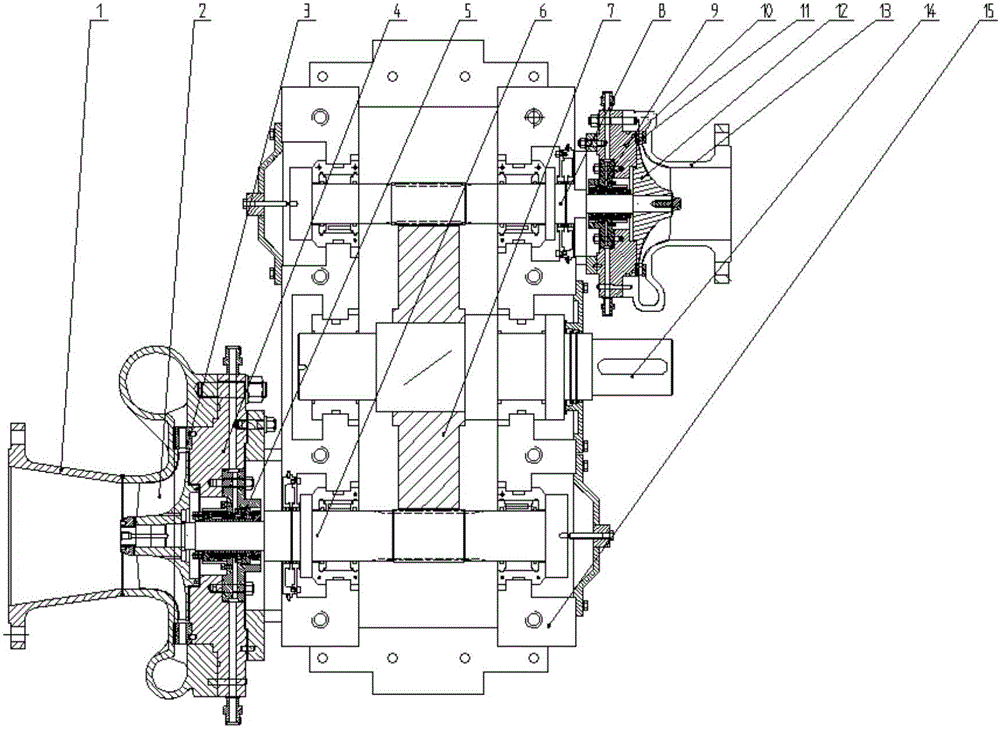

[0057] Such as Figure 1-4 As shown, a steam turbine and organic Rankine cycle working fluid turbine dual drive system provided in this embodiment includes a steam turbine subsystem, a working fluid turbine subsystem and a dual drive device;

[0058] The dual drive device includes two working fluid input terminals and one power output terminal, and the power input by the two working fluid input terminals is superimposed and then output from the power output terminal;

[0059] The steam turbine subsystem includes a waste heat boiler 16, a steam turbine 17, one side of the working fluid input end of the dual drive device, one side of the evaporator 21, a condensing water pump 18 and a feed water pump 20, and the above-mentioned components are connected in sequence to form a Independent circulatory system;

[0060] The working medium turbine subsystem includes the other side of the evaporator 21, the working medium input end on the other side of the dual drive device, the workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com