Device and method suitable for drilled hole form drawing and intra-hole obstacle taking

A hole type and hole technology, applied in earthwork drilling, measurement, wellbore/well parts, etc., can solve problems such as unstable contact, reduced drilling efficiency, and easy falling off of objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0058] The technical scheme adopted in the present invention is as follows:

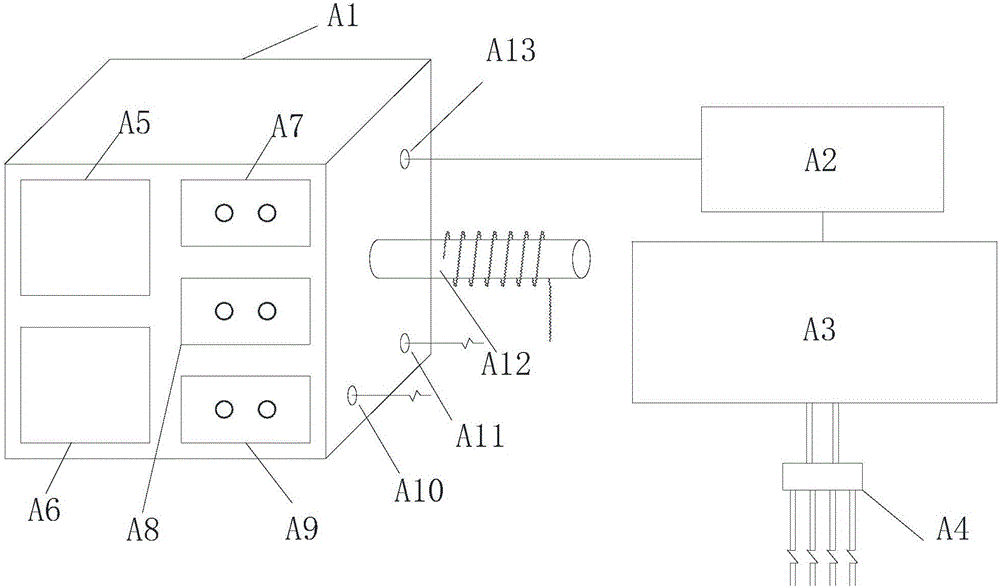

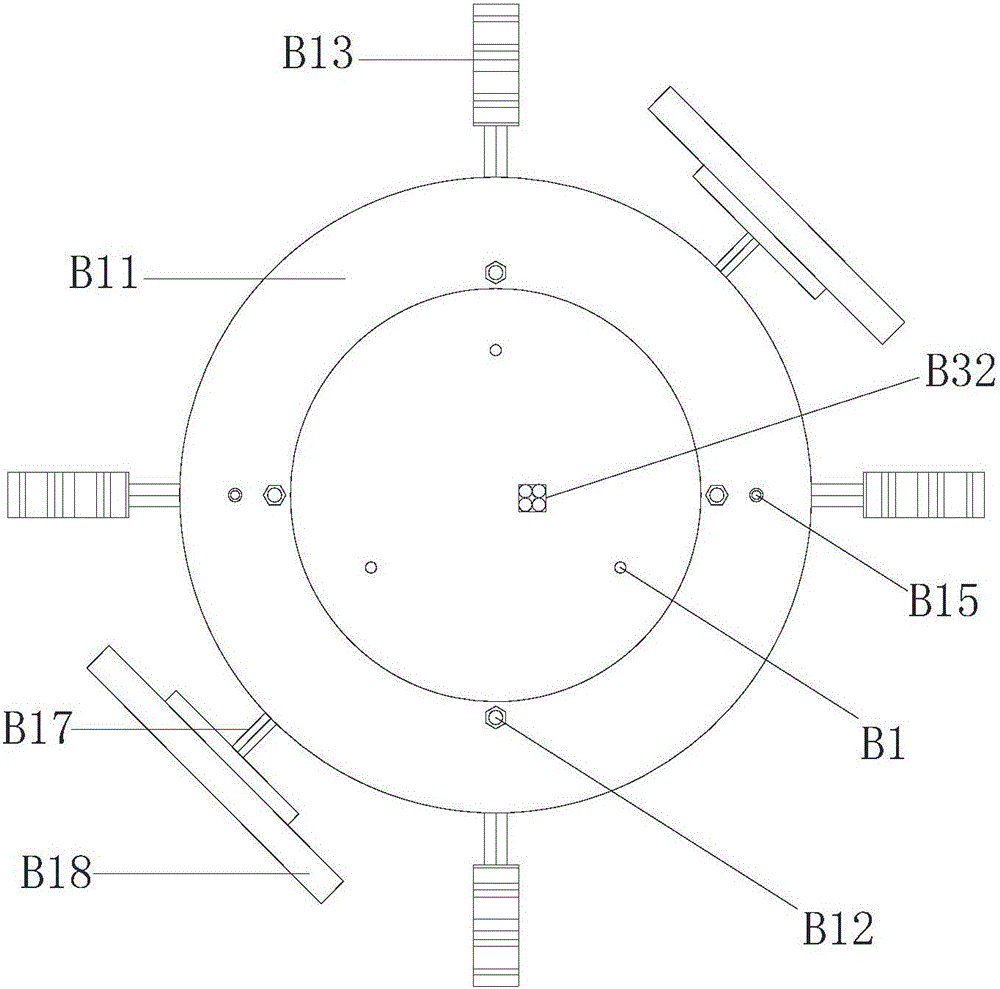

[0059] The device consists of two parts above ground and underground, namely: outside the cave visual operation module A and inside the cave fetching module B, the two parts are connected by the hoisting control area, travel control area and hydraulic control area in the outside visual operation module , the two parts are inseparable and function together as a unified whole.

[0060] The visual operation module outside the cave mainly includes console A1, oil pump A2, fuel tank A3, six-way valve A4, camera display A5, linear display A6, hoisting control area, travel control area and hydraulic control area.

[0061] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com