A method for constructing an independent brick masonry earthquake-resistant cave dwelling

A construction method and brick masonry technology, applied in the direction of building structure, building, building components, etc., can solve the problems of weak integrity, easy collapse, and poor seismic performance of cave dwellings, so as to enhance the integrity and anti-collapse performance, reduce The amount of work and the effect of improving the seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

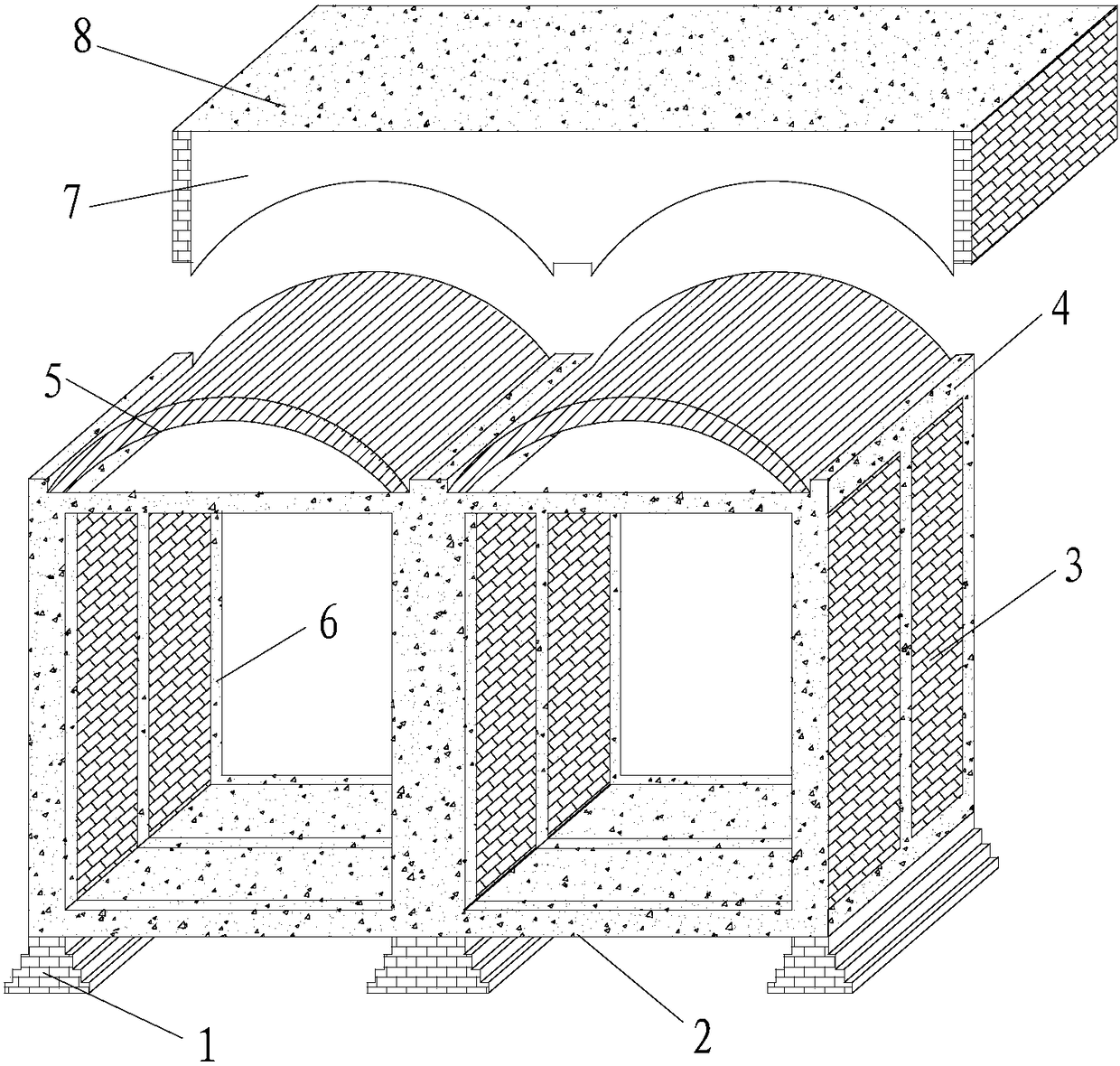

[0024] refer to figure 1 , the present invention provides a kind of free-standing brick masonry earthquake-resistant cave dwelling, comprising brick foundation 1, foundation ring beam 2, brick masonry wall body 3, upper ring beam 4, arched roof 5, structural column 6, covering soil 7 and waterproof Protective layer 8; the brick foundation 1 is two brick foundations arranged in parallel, the upper part of the brick foundation 1 is provided with a foundation ring beam 2, and the upper part of the foundation ring beam 2 corresponds to the two sides of the brick foundation 1, and respectively vertically arranged brick masonry walls 3. The upper end of the brick wall 3 is provided with an upper ring beam 4, and the two ends and the middle of the brick wall 3 are respectively vertically provided with structural columns 6, and the lower ends of the structural columns 6 are respectively connected with the foundation ring beam 2, and the structural columns The upper ends of 6 are respe...

Embodiment 2

[0029] Step 1, using viscous fiber mortar and brick blocks to build three brick foundations in parallel, and pouring reinforced concrete foundation ring beams on the brick foundations;

[0030] Step 2, using viscous fiber mortar and raw earth bricks to vertically build brick masonry walls on the foundation ring beam corresponding to the brick foundation, and at the two ends and the middle of the brick masonry walls Concrete is poured for each structural column;

[0031] Step 3, pouring an upper ring beam on the upper part of the brick masonry wall, and building a brick arch roof on the upper ring beam;

[0032] Step 4, finally covering and ramming the top of the brick arch roof of the cave dwelling, and pouring concrete on the upper part of the covering soil to form a waterproof protective layer.

[0033] in,

[0034] In step 1, the raw material components of the viscous fiber mortar include: cement, fly ash, sand, redispersible latex powder, hydroxypropyl methylcellulose an...

Embodiment 3

[0039]The viscous fiber mortar in embodiment 1 or 2 is carried out mechanical performance test, specifically as follows:

[0040] A cube test block of viscous fiber mortar was made by using a standard test mold of 70.7mm×70.7mm×70.7mm, and it was cured in a natural state (room temperature) for 30 days (the first 7 days were watered and cured), and the cubic compressive strength test was carried out. The test results show that the average compressive strength of the viscous fiber mortar test block is 21.7MPa.

[0041] A 40mm×40mm×4mm mold was used to make a tensile test block on the raw earth brick block, and it was cured for 30 days according to the standard curing method (the temperature in the curing room was 20±3 degrees, and the humidity was above 90%), and a direct tensile test was carried out. The results show that: the average uniaxial tensile strength of the raw earth brick block specimens built with viscous fiber mortar is 0.77MPa, and the failure surface occurs in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com