A seed crystal axis and method for growing silicon carbide in liquid phase

A liquid phase growth, silicon carbide technology, applied in chemical instruments and methods, single crystal growth, single crystal growth and other directions, to achieve the effect of ensuring crystal quality and growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

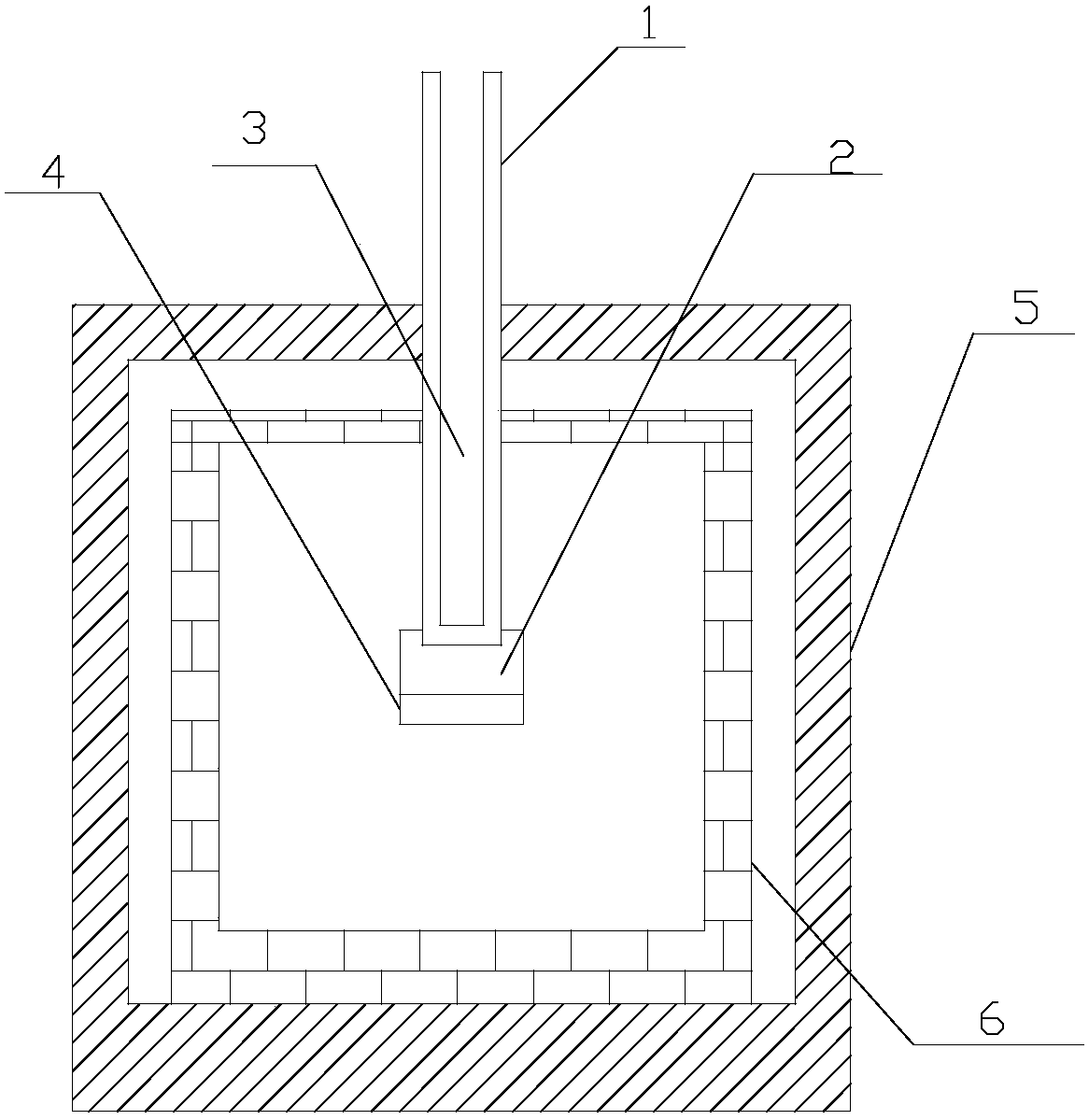

[0018] A seed shaft for liquid-phase growth of silicon carbide, comprising a graphite shaft 1, a graphite shaft cap 2 is connected to the lower end of the graphite shaft 1, and the graphite shaft cap 2 has a hollow structure;

[0019] The graphite shaft cap 2 and the graphite shaft 1 are connected by threads.

[0020] Using the above-mentioned method of growing silicon carbide in the liquid phase of the seed shaft, an inert gas is introduced into the growth chamber during the growth of the silicon carbide.

[0021] The inert gas is helium.

[0022] A temperature measuring hole 3 is provided in the middle of the graphite shaft 1.

[0023] In order to further increase heat dissipation, the height of the graphite shaft cap 2 is 10 cm.

Embodiment 2

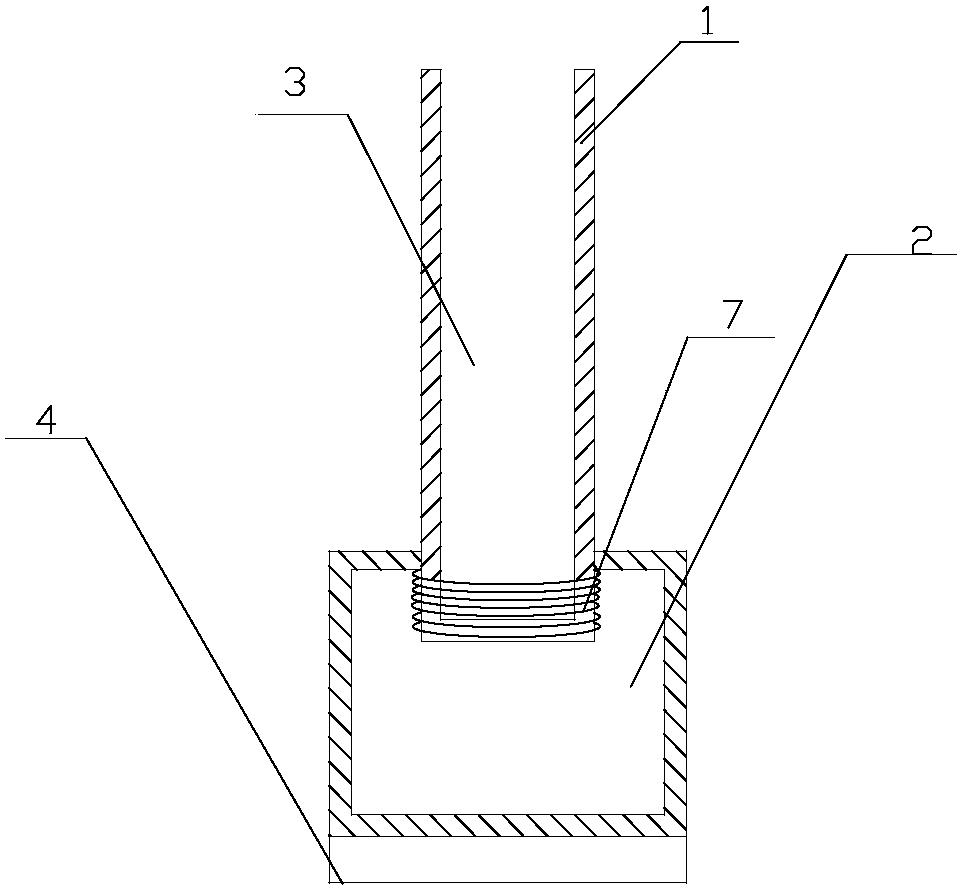

[0025] A seed shaft for liquid-phase growth of silicon carbide, comprising a graphite shaft 1, a graphite shaft cap 2 is connected to the lower end of the graphite shaft 1, and the graphite shaft cap 2 has a hollow structure;

[0026] The graphite shaft cap 2 and the graphite shaft 1 are connected by a buckle.

[0027] Using the above-mentioned method of growing silicon carbide in the liquid phase of the seed shaft, an inert gas is introduced into the growth chamber during the growth of the silicon carbide.

[0028] The inert gas is helium.

[0029] A temperature measuring hole 3 is provided in the middle of the graphite shaft 1.

[0030] To further increase heat dissipation, the height of the graphite shaft cap 2 is 5 cm.

Embodiment 3

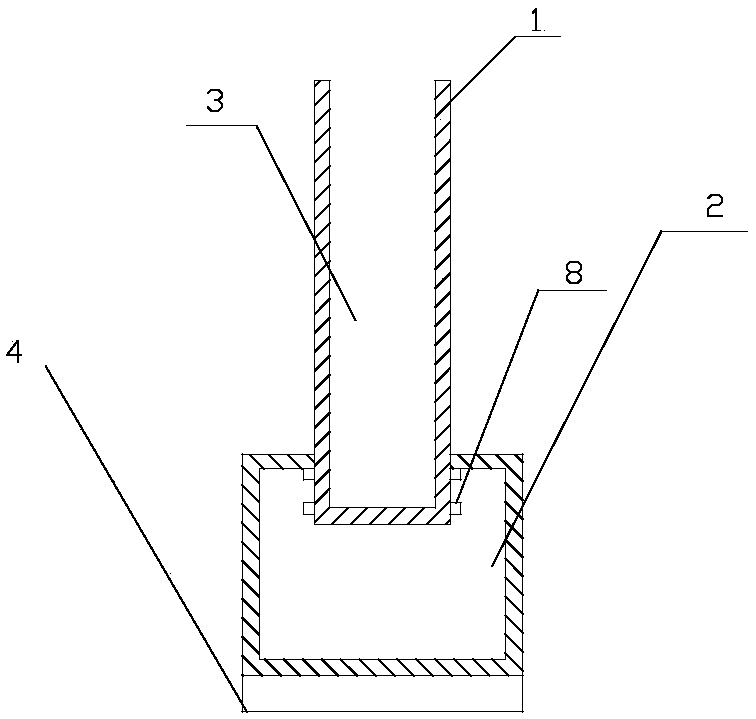

[0032] A seed shaft for liquid-phase growth of silicon carbide, comprising a graphite shaft 1, a graphite shaft cap 2 is connected to the lower end of the graphite shaft 1, and the graphite shaft cap 2 has a hollow structure;

[0033] The graphite shaft cap 2 and the graphite shaft 1 are connected by threads.

[0034] A temperature measuring hole 3 is provided in the middle of the graphite shaft 1.

[0035] Using the above-mentioned method of growing silicon carbide in the liquid phase of the seed shaft, an inert gas is introduced into the growth chamber during the growth of the silicon carbide.

[0036] The inert gas is argon.

[0037] The height of the graphite shaft cap 2 is 1 cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com