Method for preparing spherical nanomonocrystalline particle

A quartz particle and nano-single crystal technology, which is applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of quartz particle agglomeration, irregular shape, high production cost, etc., and achieve high solubility and low production cost , to avoid the effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1 gram of NaOH and 2 grams of NaCl were respectively added to 71.5 grams of 30nm colloidal silicon dioxide solution with a concentration of 3.84% (weight), and mixed evenly. Then, the mixture was poured into a polytetrafluoroethylene hydrothermal reaction kettle, the temperature was raised to 200°C at 5°C / min, the pressure was 18 atmospheres, and the temperature was kept constant for 72 hours. After cooling, it was settled by centrifugation, washed twice with water, dried at 120°C, and collected.

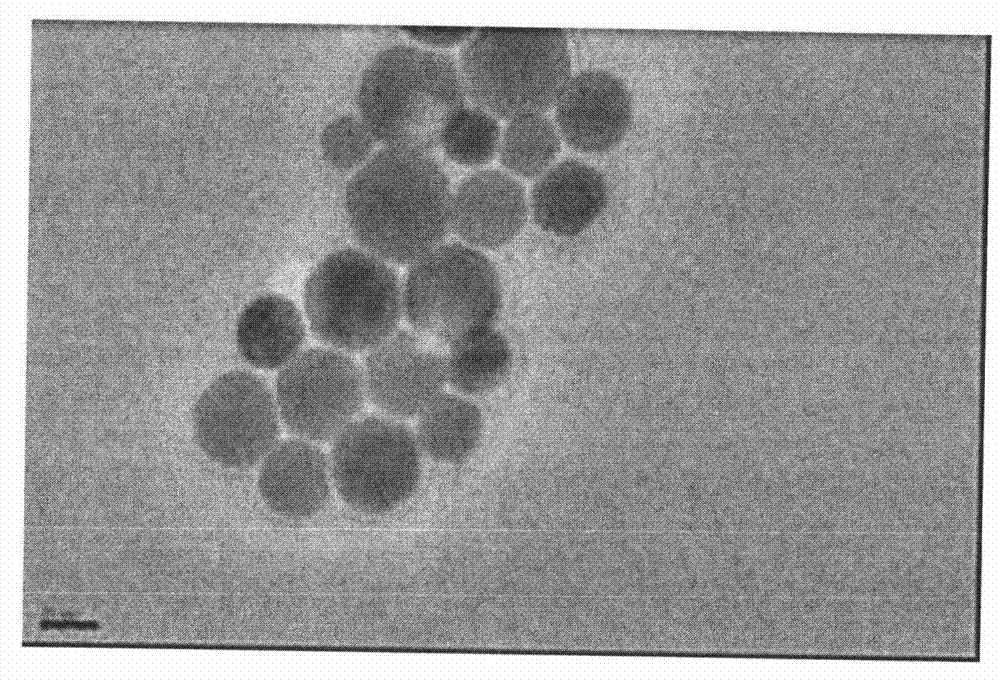

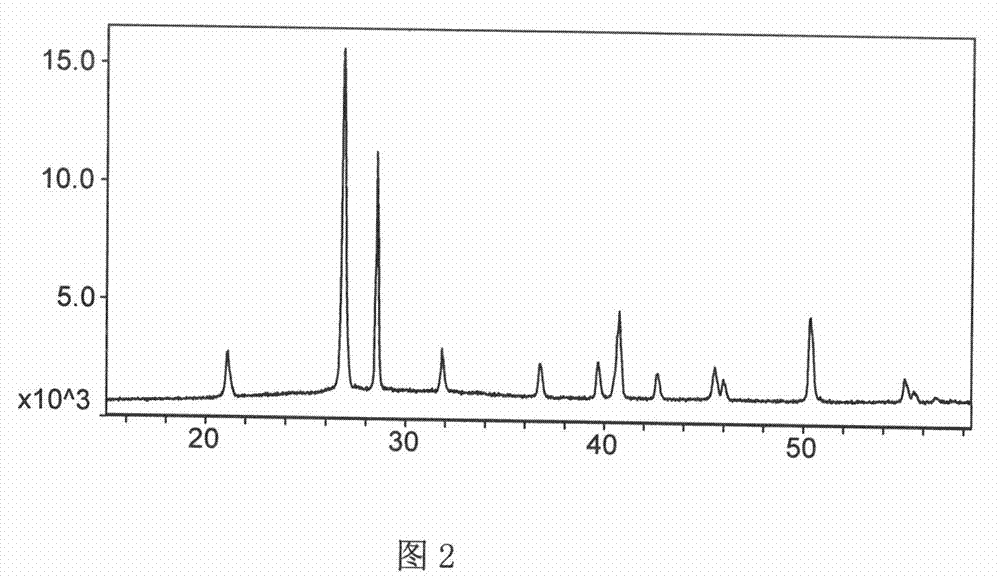

[0034] Transmission electron microscope pictures as figure 1 As shown in the transmission electron microscope images of these nano-quartz powder samples, it can be seen that the particles are spherical, non-agglomerated, monodisperse, and uniform in size. High-resolution transmission electron microscopy shows that these spherical particles have regular lattices. Each nano-quartz particle is a quartz single crystal, and the diameter of the particle is about 28nm.

[0035] T...

Embodiment 2

[0038] 4 grams of KOH and 1 gram of KCl were respectively added to 71.5 grams of 35nm colloidal silica solution with a concentration of 3.84% (weight), and mixed evenly. Then, pour this mixture into a polytetrafluoroethylene hydrothermal reaction kettle, stir it magnetically, raise the temperature to 150°C at 5°C / min, and keep the temperature constant for 48 hours at a pressure of 14 atmospheres. After cooling, it was settled by centrifugation, washed twice with water, dried at 150°C, and collected.

[0039] Transmission electron microscope pictures show that the particles are spherical, non-agglomerated, monodisperse, and uniform in size. High-resolution transmission electron microscopy shows that these spherical particles have regular lattices. Each nano-quartz particle is a quartz single crystal, and the diameter of the particle is about 20nm. The product after hydrothermal synthesis is a mixture of NaCl and α-quartz. The powder sample was washed and dried by centrifugal ...

Embodiment 3

[0042] 1 gram of NaOH and 4 grams of KCl were respectively added to 150 grams of 100 nanometer colloidal silicon dioxide solution with a concentration of 4.5% (weight), and mixed evenly. Then, pour this mixture into a polytetrafluoroethylene hydrothermal reaction kettle, stir it magnetically, raise the temperature to 150°C at 5°C / min, and keep the temperature constant for 24 hours at a pressure of 5 atmospheres. After cooling, it was settled by centrifugation, washed three times with water, dried at 100°C, and collected.

[0043] Transmission electron microscope pictures show that the particles are spherical, non-agglomerated, monodisperse, and uniform in size. High-resolution transmission electron microscopy shows that these spherical particles have regular lattices. Each nano-quartz particle is a quartz single crystal, and the diameter of the particle is about 80nm. The product after hydrothermal synthesis is a mixture of KCl and α-quartz. The powder sample was washed and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com