Two-dimensional expansion method for CVD monocrystal diamond

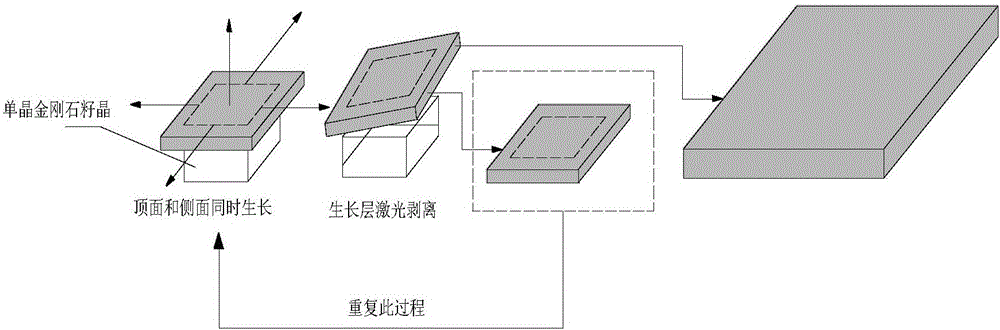

A technology of single crystal diamond and seed crystal, which is applied in the field of manufacturing single crystal diamond materials, can solve the problems of low expansion efficiency, cumbersome operation process, complicated three-dimensional expansion technology, etc., and achieve the effect of size expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

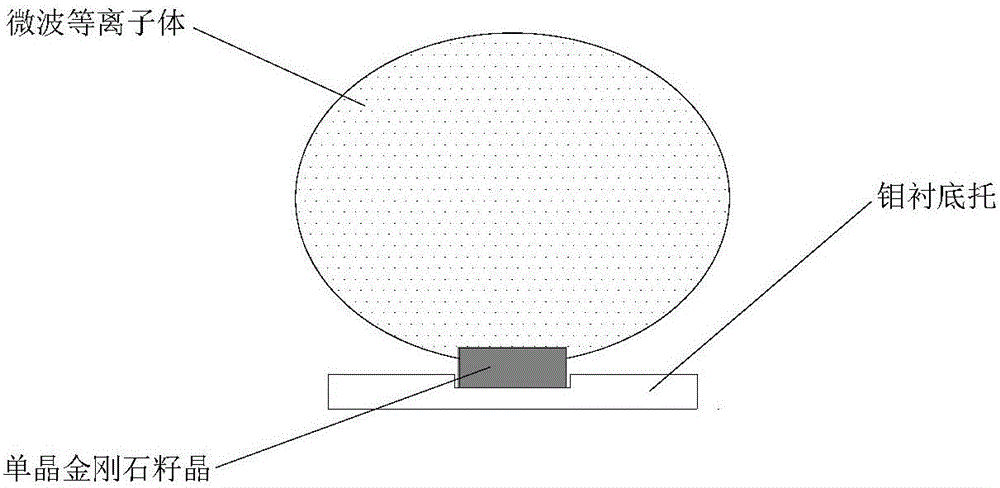

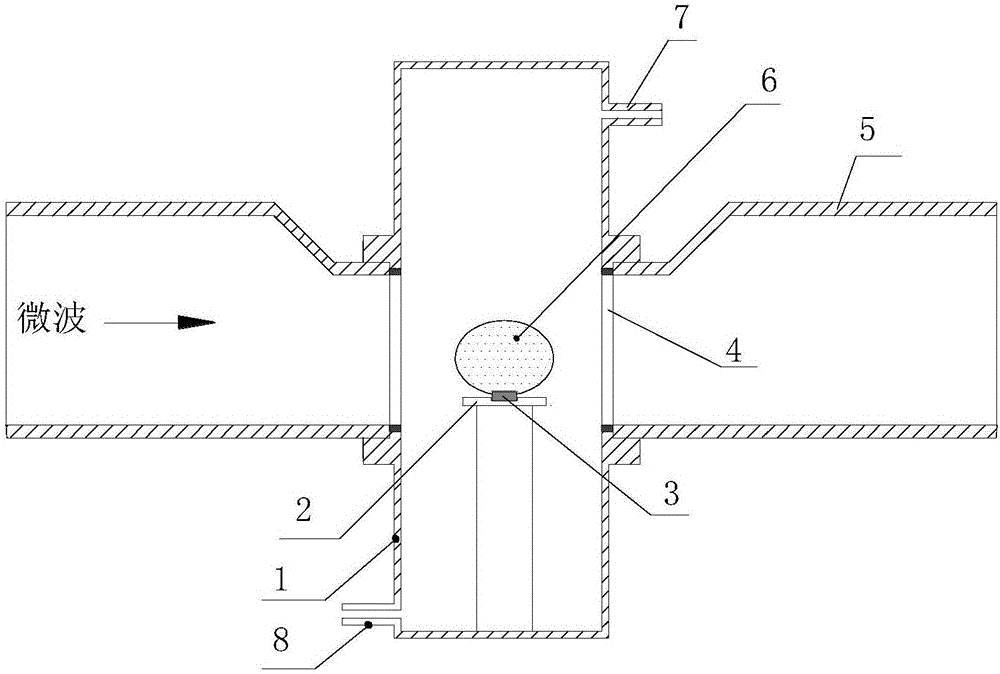

[0023] As shown in Figure 3, the device for growing single crystal diamond adopted in the following embodiments of the present invention comprises a deposition chamber, a substrate holder, and a microwave generator; the deposition chamber 1 is composed of an upper metal flange, a lower metal flange and a compression The rectangular waveguide 5 is connected, and the compressed rectangular waveguide 5 is connected with the microwave generator; the deposition chamber 1 is provided with an air inlet and an air outlet; the center of the substrate holder is provided with a hole (or groove).

[0024] The deposition chamber 1 comprises a quartz glass tube, an upper metal flange, and a lower metal flange (constituting a chamber). The upper metal flange is located at the upper end of the quartz glass tube, and a rubber sealing ring is arranged between the upper me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com