Surface modification method for titanium alloy

A surface modification, titanium alloy technology, applied in metal material coating process, coating, fusion spraying, etc., can solve the problems of low surface hardness and poor wear resistance of titanium alloy, and achieve surface structure and performance improvement, energy High interest rate, the effect of improving special physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

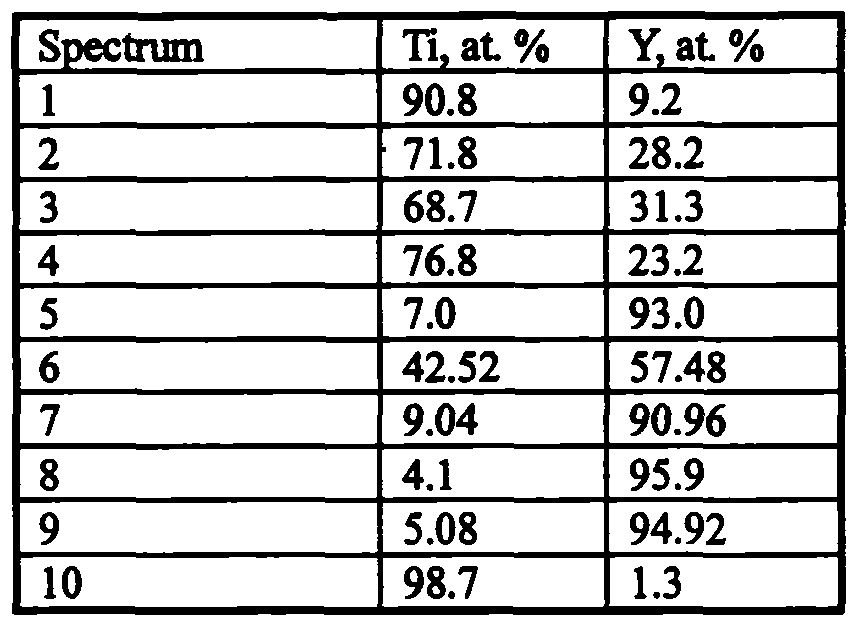

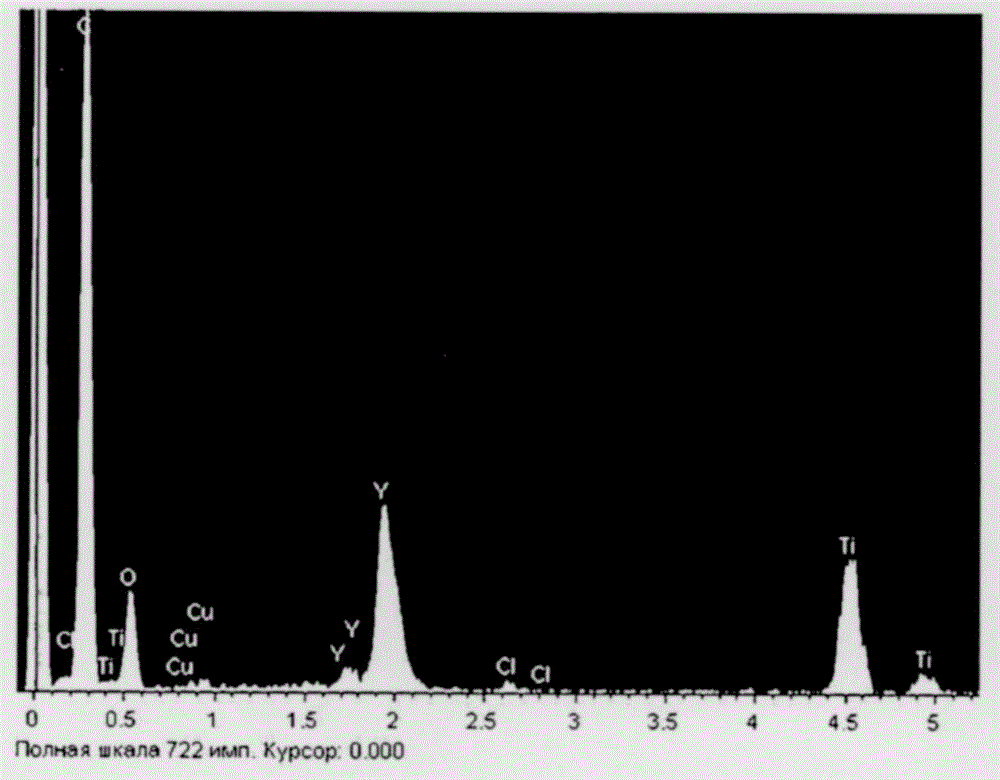

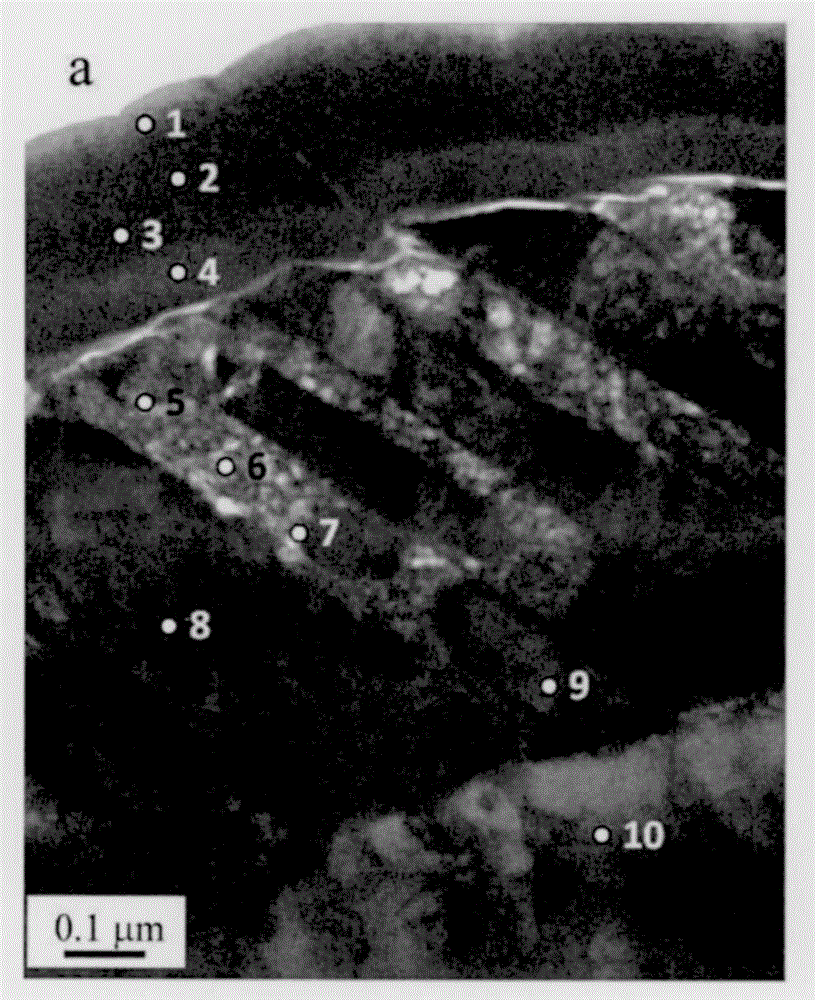

[0022] Figure 1 and figure 2 Said, a method for surface modification of titanium alloy, the titanium foil adopts industrial pure titanium VT1-0, the surface of the titanium foil is alloyed by electric explosion technology, and the yttrium metal powder is used as the cathode. The technical parameters of electric explosion are: the absorbed power density at the jet axis is 5.5GW / m 2 , the plasma action time is 100μs, and the gas residual pressure in the working chamber is 100Pa. The process parameters for modifying the surface of the alloyed titanium foil by high-current pulsed electron beam irradiation technology are: electron energy 18kev, electron beam energy density 50J / cm 2 , the number of pulses is 3 times, the pulse time is 150μs, and the frequency is 0.3Hz. The above two steps are completed in a vacuum state.

[0023] Such as figure 2 As shown, the microstructural diagrams of titanium alloy surface modification layer and titanium alloy layer under different scales, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com