Quenched and tempered high-strength alloy steel 06Ni9DR steel plate used for ultralow-temperature pressure container and preparation method of quenched and tempered high-strength alloy steel 06Ni9DR steel plate

A pressure vessel and ultra-low temperature technology, which is applied in the field of steel plates for pressure vessels and its preparation, can solve the problems of dependence on imports and the difficulty of producing 06Ni9DR steel plates, and achieve the effects of avoiding welding magnetic deflection, good low-temperature performance, and good post-weld performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]A quenched and tempered high-strength alloy steel 06Ni9DR steel plate for ultra-low temperature pressure vessels, including the following chemical components in mass percentages (unit, wt%): C: 0.01, Si: 0.20, Mn: 0.50, P: 0.006, S: 0.002, Ni : 8.5, Cu: 0.10, Mo: 0.01, V: 0.005, Cr: 0.10, Als: 0.015, N: 0.012, and the balance is Fe and unavoidable impurities.

[0032] Wherein, the carbon equivalent of the alloy steel plate [Ceq=C+Mn / 6+(Cr+V+Mo) / 5+(Cu+Ni) / 15]=0.10%, and the thickness of the steel plate is 12mm.

[0033] Its preparation method comprises the following steps:

[0034] (1) KR hot metal pretreatment: use the ladle to carry the hot metal, remove the former slag from the hot metal at the station, control the content of P and S in the hot metal, after the hot metal is stirred and desulfurized by KR, the hot metal P≤0.1%, S≤0.004%, and the desulfurization cycle≤25min , desulfurization temperature drop ≤ 20 ℃; after desulfurization is completed, the slag layer is ...

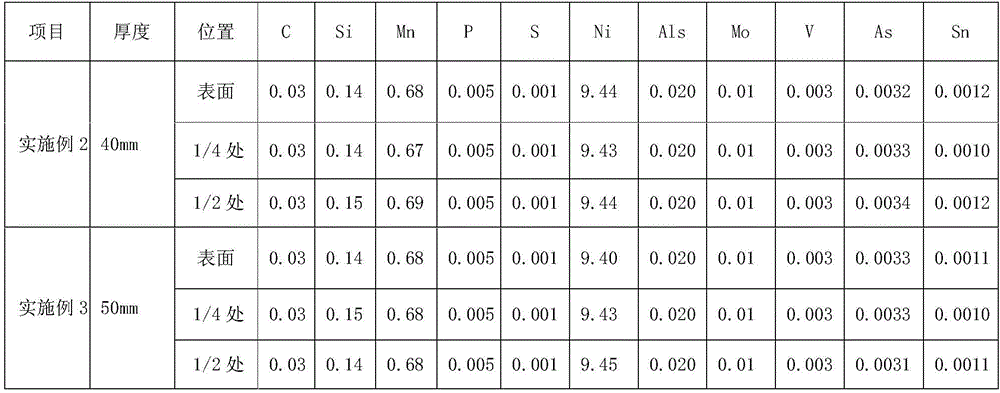

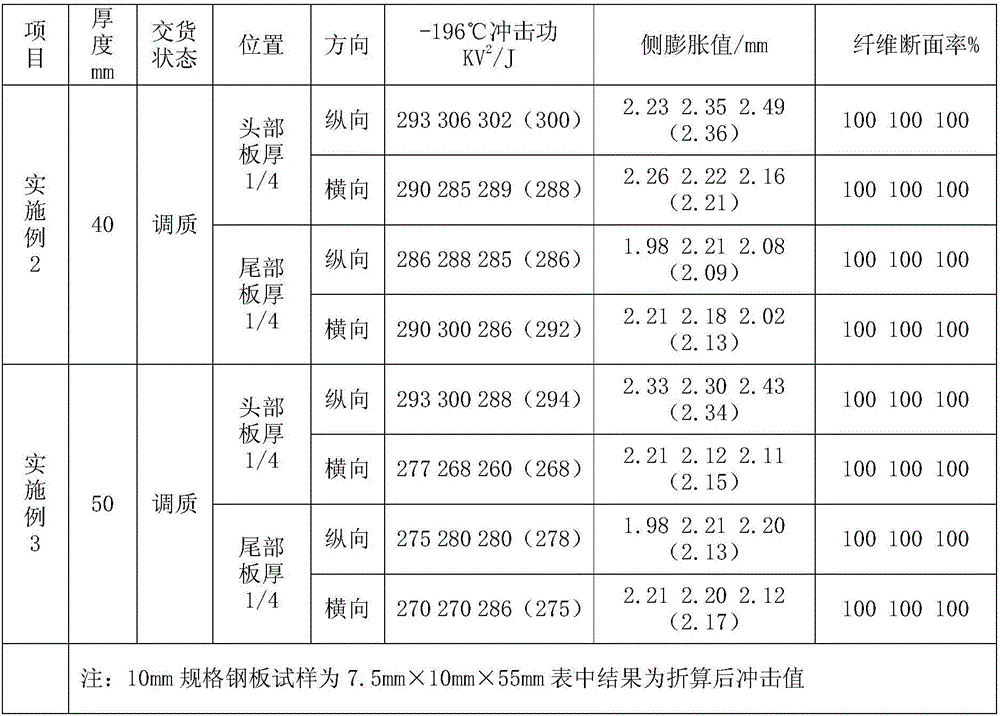

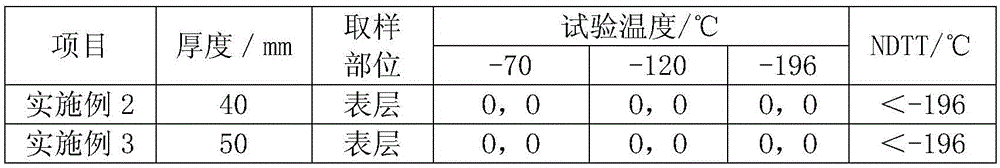

Embodiment 2

[0047] A quenched and tempered high-strength alloy steel 06Ni9DR steel plate for ultra-low temperature pressure vessels, including the following chemical components in mass percentages (unit, wt%): C: 0.03, Si: 0.14, Mn: 0.69, P: 0.005, S: 0.001, Ni : 9.4, Cu: 0.01, Mo: 0.01, V: 0.003, Cr: 0.25, Als: 0.020, N: 0.00189, and the balance is Fe and unavoidable impurities.

[0048] Wherein, the carbon equivalent of the alloy steel plate [Ceq=C+Mn / 6+(Cr+V+Mo) / 5+(Cu+Ni) / 15]=0.50%, and the thickness of the steel plate is 40mm.

[0049] Its preparation method comprises the following steps:

[0050] (1) KR hot metal pretreatment: use the ladle to carry the hot metal, remove the former slag from the hot metal at the station, control the content of P and S in the hot metal, after the hot metal is stirred and desulfurized by KR, the hot metal P≤0.1%, S≤0.004%, and the desulfurization cycle≤25min , desulfurization temperature drop ≤ 20 ℃; after desulfurization is completed, the slag layer ...

Embodiment 3

[0063] A quenched and tempered high-strength alloy steel 06Ni9DR steel plate for ultra-low temperature pressure vessels, including the following chemical components in mass percent (unit, wt%): C: 0.03, Si: 0.14, Mn: 0.68, P: 0.005, S: 0.001, Ni : 9.4, Cu: 0.09, Mo: 0.01, V: 0.003, Cr: 0.20, Als: 0.020, N: 0.00195, and the balance is Fe and unavoidable impurities.

[0064] Wherein, the carbon equivalent of the alloy steel plate [Ceq=C+Mn / 6+(Cr+V+Mo) / 5+(Cu+Ni) / 15]=0.15%, and the thickness of the steel plate is 50mm.

[0065] Its preparation method comprises the following steps:

[0066] (1) KR hot metal pretreatment: use the ladle to carry the hot metal, remove the former slag from the hot metal at the station, control the content of P and S in the hot metal, after the hot metal is stirred and desulfurized by KR, the hot metal P≤0.1%, S≤0.004%, and the desulfurization cycle≤25min , desulfurization temperature drop ≤ 20 ℃; after desulfurization is completed, the slag layer is s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com