A magnesium-based bulk amorphous alloy with obvious plasticity and its preparation method

An amorphous alloy and plastic technology, applied in the field of magnesium-based bulk amorphous alloy and its preparation, can solve the problems of limited preparation size, easy brittle fracture, uneven melting, etc., and achieve good biocompatibility and osseointegration performance, increase corrosion potential, and broaden the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

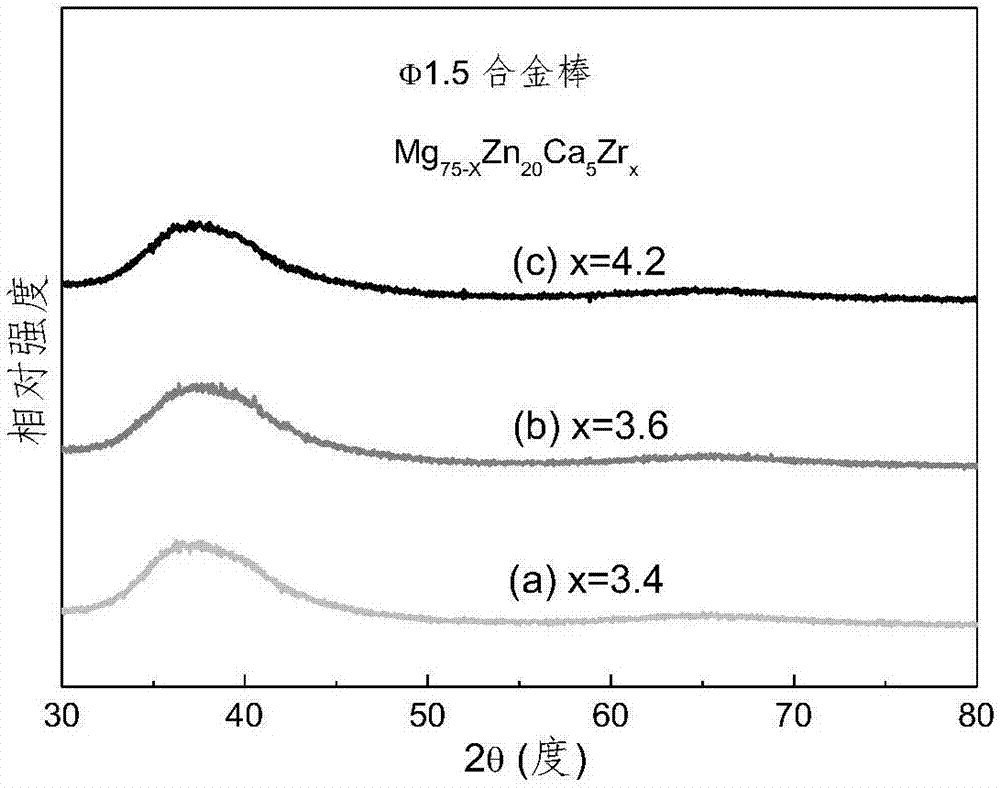

Embodiment 1

[0033] According to the atomic percentage of each element in the target alloy: Mg is 71.6%, Zn is 20%, Ca is 5%, Zr is 3.4%, weighing 99.99% pure magnesium, 99.99% pure zinc, 99.99% pure calcium, 99.99% pure zirconium is mixed to obtain the master alloy raw material; then the master alloy raw material is placed in a vacuum induction melting furnace, and when the mechanical pump is used to draw a low vacuum to 5Pa, the molecular pump is used to draw a high vacuum to 9×10 -4 Pa, and then under the protection of argon, the master alloy was repeatedly smelted 3 times (the master alloy needs to be stirred each time), and the electromagnetic stirring was turned on during the smelting process to ensure the uniformity of the alloy structure. Mg can be obtained by cooling in the furnace 71.6 Zn 20 Ca 5 Zr 3.4 alloy ingot.

[0034] High vacuum to 8×10 -4 Pa, the Mg-Zn-Ca-Zr alloy ingot obtained in the first step is melted using a resistance furnace, and when the furnace temperature...

Embodiment 2

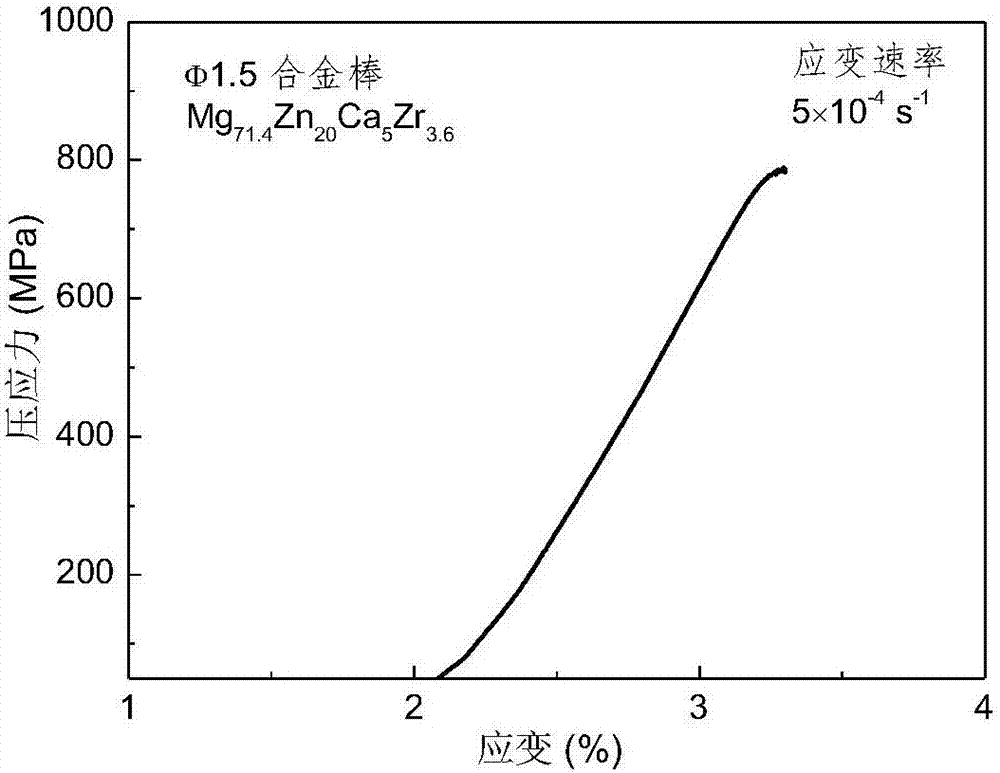

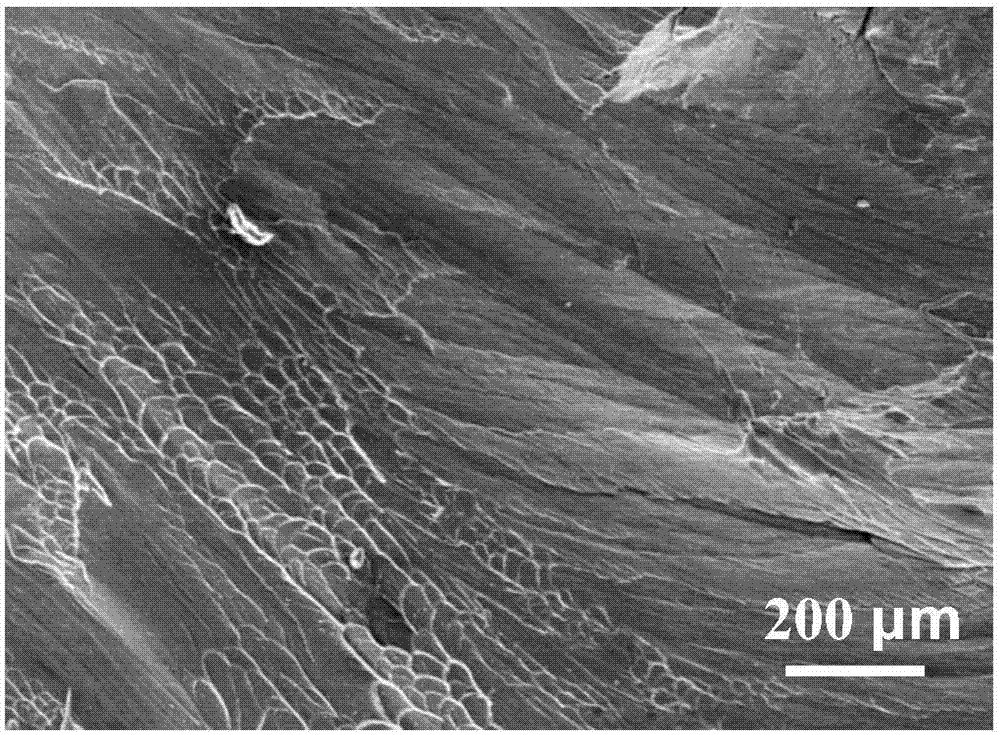

[0039] According to the atomic percentage of each element in the target alloy: Mg is 71.4%, Zn is 20%, Ca is 5%, Zr is 3.6%, weighing 99.99% pure magnesium, 99.99% pure zinc, 99.99% pure calcium, 99.99% pure zirconium is mixed to obtain the master alloy raw material; then the master alloy raw material is placed in a vacuum induction melting furnace, and when the mechanical pump is used to draw a low vacuum to 5Pa, the molecular pump is used to draw a high vacuum to 7.5×10 -4 Pa, and then under the protection of argon, the master alloy was repeatedly smelted 5 times (the master alloy needs to be stirred each time), and the electromagnetic stirring was turned on during the smelting process to ensure the uniformity of the alloy structure. Mg can be obtained by cooling in the furnace 71.4 Zn 20 Ca 5 Zr 3.6 alloy ingot.

[0040] First pump high vacuum to 7.5×10 -4 When Pa, the Mg-Zn-Ca-Zr alloy ingot obtained in the first step is melted in a resistance furnace, and the refinin...

Embodiment 3

[0045] According to the atomic percentage of each element in the target alloy: Mg is 71%, Zn is 20%, Ca is 5%, Zr is 4%, weighing 99.99% pure magnesium, 99.99% pure zinc, 99.99% pure calcium, 99.99% pure zirconium is mixed to obtain the master alloy raw material; then the master alloy raw material is placed in a vacuum induction melting furnace, and when the mechanical pump is used to draw a low vacuum to 5Pa, the molecular pump is used to draw a high vacuum to 7×10 -4 Pa, and then under the protection of argon, the master alloy was repeatedly smelted 4 times (the master alloy needs to be stirred each time), and the electromagnetic stirring was turned on during the smelting process to ensure the uniformity of the alloy structure. Mg can be obtained by cooling in the furnace 71 Zn 20 Ca 5 Zr 4 alloy ingot.

[0046] First pump high vacuum to 7×10 -4 When Pa, the Mg-Zn-Ca-Zr alloy ingot obtained in the first step is melted in a resistance furnace, and the refining agent whos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com