A method and system for solvent extraction and solvent recovery of carbonate-rich oil sands

A solvent recovery device and carbonate technology, applied in the field of operation, can solve the problems of solvent leakage and oil sand separation, and other problems, and achieve the effects of improving solvent utilization efficiency, good economic and environmental benefits, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

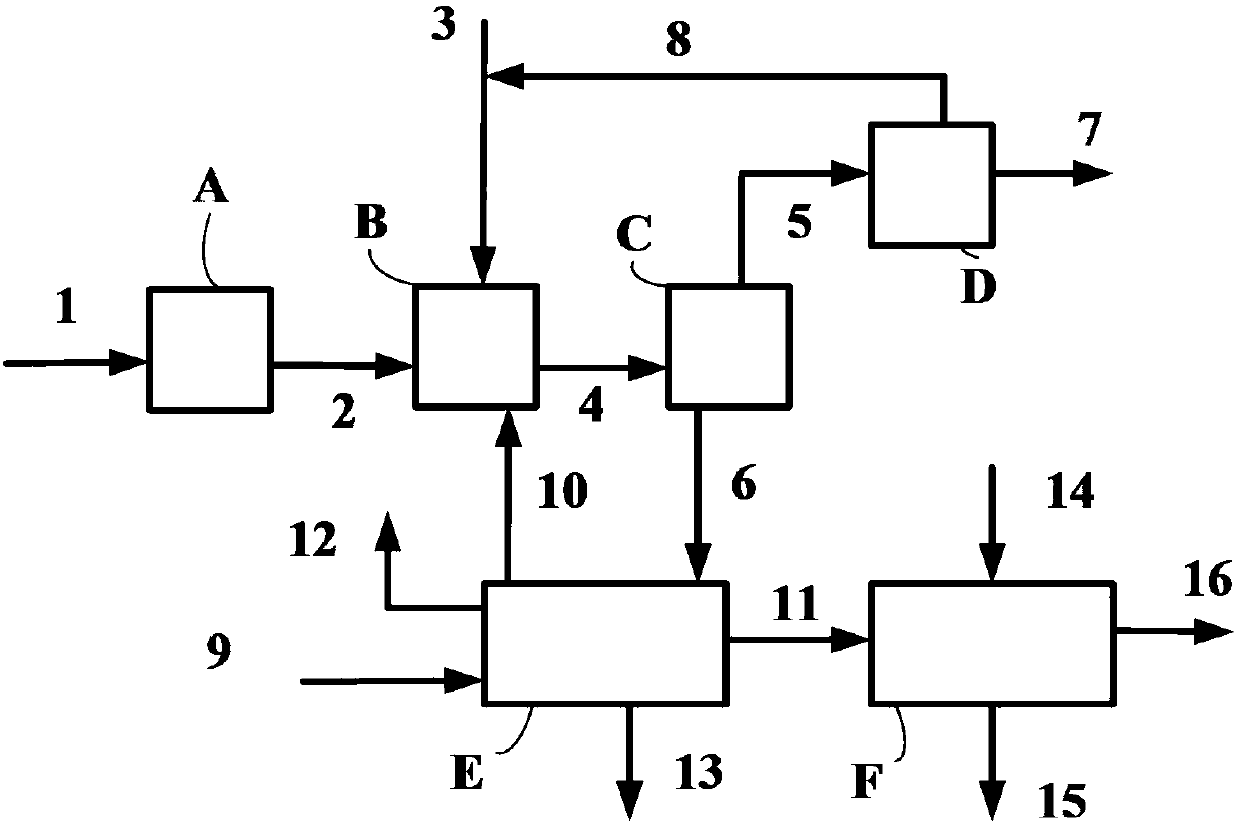

[0044] A method and system for solvent extraction of oil sands rich in carbonate, the operation steps are as follows:

[0045] (1) The small particles of oil sand ore crushed by the crushing device (the carbonate content accounts for 52.1% of the mineral salt, and the particles are less than 3cm) and toluene are mixed and stirred at 0°C for 30 minutes according to the liquid-solid mass ratio of 1:1;

[0046] (2) The extraction mixture extracted from the extraction device is transported to the solid-liquid separation device for solid-liquid separation, and the supernatant solvent asphalt oil clear liquid is extracted to the solvent recovery device for solvent-asphalt oil separation operation to obtain circulating solvent and asphalt oil products;

[0047] (3) Residual solids (mineral particles and a small amount of solvent oil mixture) at the bottom of the above obtained react with 3mol / L hydrochloric acid solution in the tailings pickling treatment device according to the mass ...

Embodiment 2

[0051] A method and system for solvent extraction of oil sands rich in carbonate, the operation steps are as follows:

[0052] ⑴ Small particles of oil shale ore crushed by the crushing device (carbonate content accounts for 82.1% of the mineral salt, and the particle size is less than 1cm) and naphtha (boiling point below 220°C) are 1:5 at 25 ℃ for mixing and stirring extraction for 20min;

[0053] (2) The extraction mixture extracted from the extraction device is transported to the solid-liquid separation device for solid-liquid separation, and the supernatant solvent asphalt oil clear liquid is extracted to the solvent recovery device for solvent-asphalt oil separation operation to obtain circulating solvent and asphalt oil products;

[0054] (3) Residual solids (mineral particles and a small amount of solvent oil mixture) at the bottom obtained above react with 0.1mol / L sulfuric acid solution in the tailings pickling treatment device according to the mass ratio of 1:10 to ...

Embodiment 3

[0058] A method and system for solvent extraction of oil sands rich in carbonate, the operation steps are as follows:

[0059] (1) The oil sludge small particles crushed by the crushing device (the carbonate content accounts for 10.1% of the mineral salt, and the particles are less than 0.5cm) and kerosene are sealed, mixed and extracted at 55°C for 60 minutes according to the liquid-solid mass ratio of 1:10;

[0060] (2) The extraction mixture extracted from the extraction device is transported to the solid-liquid separation device for solid-liquid separation, and the supernatant solvent asphalt oil clear liquid is extracted to the solvent recovery device for solvent-asphalt oil separation operation to obtain circulating solvent and asphalt oil products;

[0061] (3) Residual solids (mineral particles and a small amount of solvent oil mixture) at the bottom obtained above react with 5mol / L formic acid solution in the tailings pickling treatment device according to the mass rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com