UV roller painting open clear primer and preparing method thereof

A primer and roller coating technology, which is applied in the field of paint, can solve the problems of easy-to-close conduits, poor openness, and low viscosity, and achieve the effects of fast curing speed, high production efficiency, and good adhesion of the paint film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

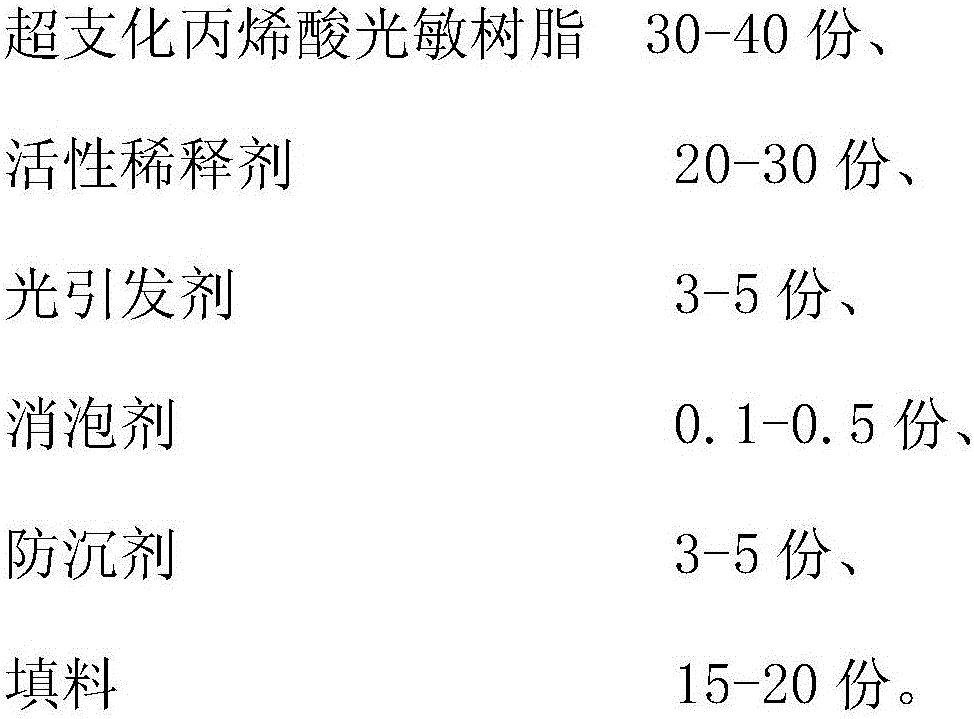

[0030] The preparation method of a kind of UV roller coating open clear primer is as follows, add hyperbranched acrylic acid photosensitive resin, reactive diluent, photoinitiator and defoamer successively in reaction vessel, stir 10-30 minutes with 1000-1500r / min to Evenly, then add anti-settling agent and filler, and finally stir at 1600-1800r / min for 15-30 minutes until the fineness is less than 40 microns.

[0031] The hyperbranched acrylic photosensitive resin described therein is preferably B-574C produced by Guangdong Boxing New Material Technology Co., Ltd., and the reactive diluent is preferably trimethylolpropane triacrylate and / or tripropylene glycol diacrylate of Sanmu Company Esters, the initiator is preferably BASF's 1173 (2-hydroxy-2-methyl-1-phenylacetone), the defoamer is preferably Tego additive Airex 920, the anti-settling agent is preferably Degussa R972, and the filler is preferably It is 1250 talc powder from Guangxi Longsheng.

[0032] (2) Embodiment

Embodiment 1

[0034] Photosensitive resin: 20 parts

[0035] Trimethylolpropane triacrylate: 30 parts

[0036] Tripropylene glycol diacrylate: 20 parts

[0037] Photoinitiator: 5 parts

[0038] Defoamer: 0.1 parts

[0039] Anti-sedimentation agent: 5 parts

[0040] Talc: 19.9 parts.

[0041] Production process: Add photosensitive resin, trimethylolpropane triacrylate, tripropylene glycol diacrylate, photoinitiator, defoamer in sequence, stir at 1500r / min for 10min until uniform, add anti-settling agent, Talc powder, then stirred at 1800r / min for 15min until the fineness is less than 40μm.

Embodiment 2

[0043] Photosensitive resin: 25 parts

[0044] Trimethylolpropane triacrylate: 25 parts

[0045] Tripropylene glycol diacrylate: 25 parts

[0046] Photoinitiator: 5 parts

[0047] Defoamer: 0.1 parts

[0048] Anti-sedimentation agent: 5 parts

[0049] Talc powder: 13.9 parts

[0050] Production process: Add photosensitive resin, trimethylolpropane triacrylate, tripropylene glycol diacrylate, photoinitiator, defoamer in sequence, stir at 1500r / min for 10min until uniform, add anti-settling agent, Talc powder, then stirred at 1800r / min for 15min until the fineness is less than 40μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com