Self-permeable light bonding material and preparation method thereof

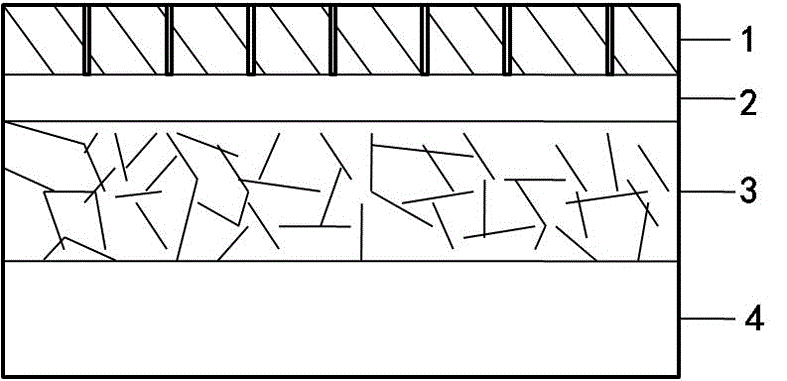

A bonding material and lightweight technology, applied in the field of road building materials and its preparation, can solve the problems of lack of self-bonding, fixing ability, decrease of water permeability of bonded leveling layer, blockage of permeable channels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A self-permeable lightweight adhesive material, which consists of the following component raw materials in parts by weight:

[0039]

[0040] The preparation method of the self-permeable lightweight adhesive material is as follows:

[0041] 1) Mix and stir 288 parts by weight of ordinary Portland cement, 32 parts by weight of mineral admixtures, 3 parts by weight of a pore connecting agent and 160 parts by weight of water to prepare cement paste;

[0042] 2) Take (commercially available) cement foaming agent, mix cement foaming agent and water according to the weight ratio of cement foaming agent: water of 1:18 to make cement foaming agent aqueous solution, and then cement foaming agent aqueous solution After being pumped to the special foaming machine for foam concrete, it is made into prefabricated foam;

[0043] 3) adding 45 parts by weight of prefabricated foam to the cement slurry, mixing and stirring to obtain a self-permeable light-weight adhesive material sl...

Embodiment 2

[0046] A self-permeable lightweight adhesive material, which consists of the following component raw materials in parts by weight:

[0047]

[0048] The preparation method of the self-permeable lightweight adhesive material is as follows:

[0049] 1) Mix and stir 408 parts by weight of ordinary Portland cement, 72 parts by weight of mineral admixtures, 5 parts by weight of a pore connecting agent, and 240 parts by weight of water to prepare cement paste;

[0050] 2) Take a (commercially available) cement foaming agent, mix the cement foaming agent with water at a weight ratio of cement foaming agent: water of 1:17 to make a cement foaming agent aqueous solution, and then mix the cement foaming agent aqueous solution After being pumped to the special foaming machine for foam concrete, it is made into prefabricated foam;

[0051] 3) Adding 42 parts by weight of prefabricated foam to the cement paste, mixing and stirring, to obtain a self-permeable lightweight bonding materia...

Embodiment 3

[0054] A self-permeable lightweight adhesive material, which consists of the following component raw materials in parts by weight:

[0055]

[0056] The preparation method of the self-permeable lightweight adhesive material is as follows:

[0057] 1) Mix and stir 448 parts by weight of ordinary Portland cement, 192 parts by weight of mineral admixtures, 6 parts by weight of a pore connecting agent and 320 parts by weight of water to prepare cement paste;

[0058] 2) Take (commercially available) cement foaming agent, mix cement foaming agent and water according to the weight ratio of cement foaming agent: water of 1:18 to make cement foaming agent aqueous solution, and then cement foaming agent aqueous solution After being pumped to the special foaming machine for foam concrete, it is made into prefabricated foam;

[0059] 3) Adding 38 parts by weight of prefabricated foam to the cement slurry prepared in step 1), mixing and stirring to obtain a self-permeable light-weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power level | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com