Carbon-nanotube covered electric wire

A technology of carbon nanotubes and coated wires, applied in the direction of carbon nanotubes, nanocarbons, circuits, etc., can solve problems such as difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~32、 comparative example 1~8

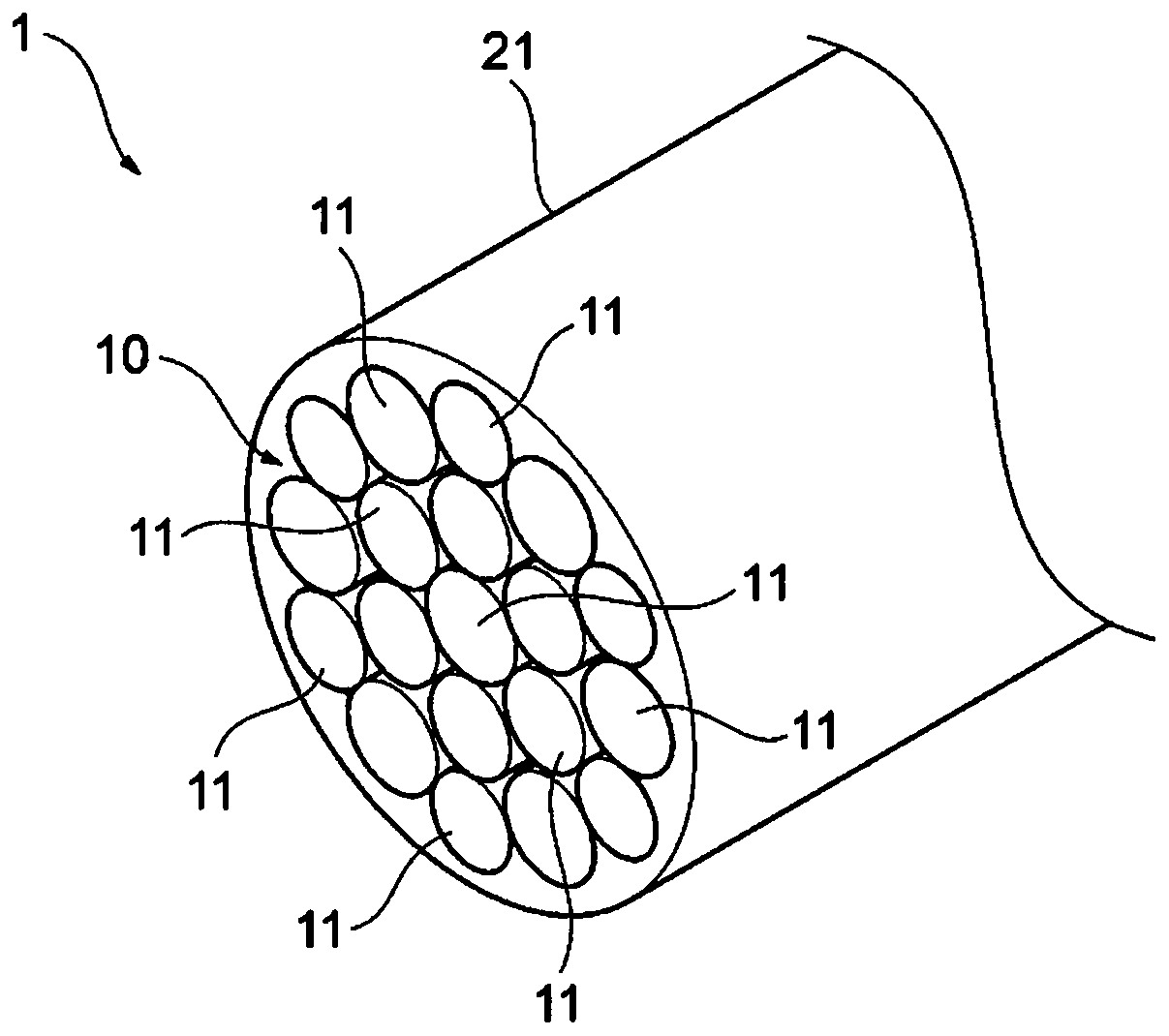

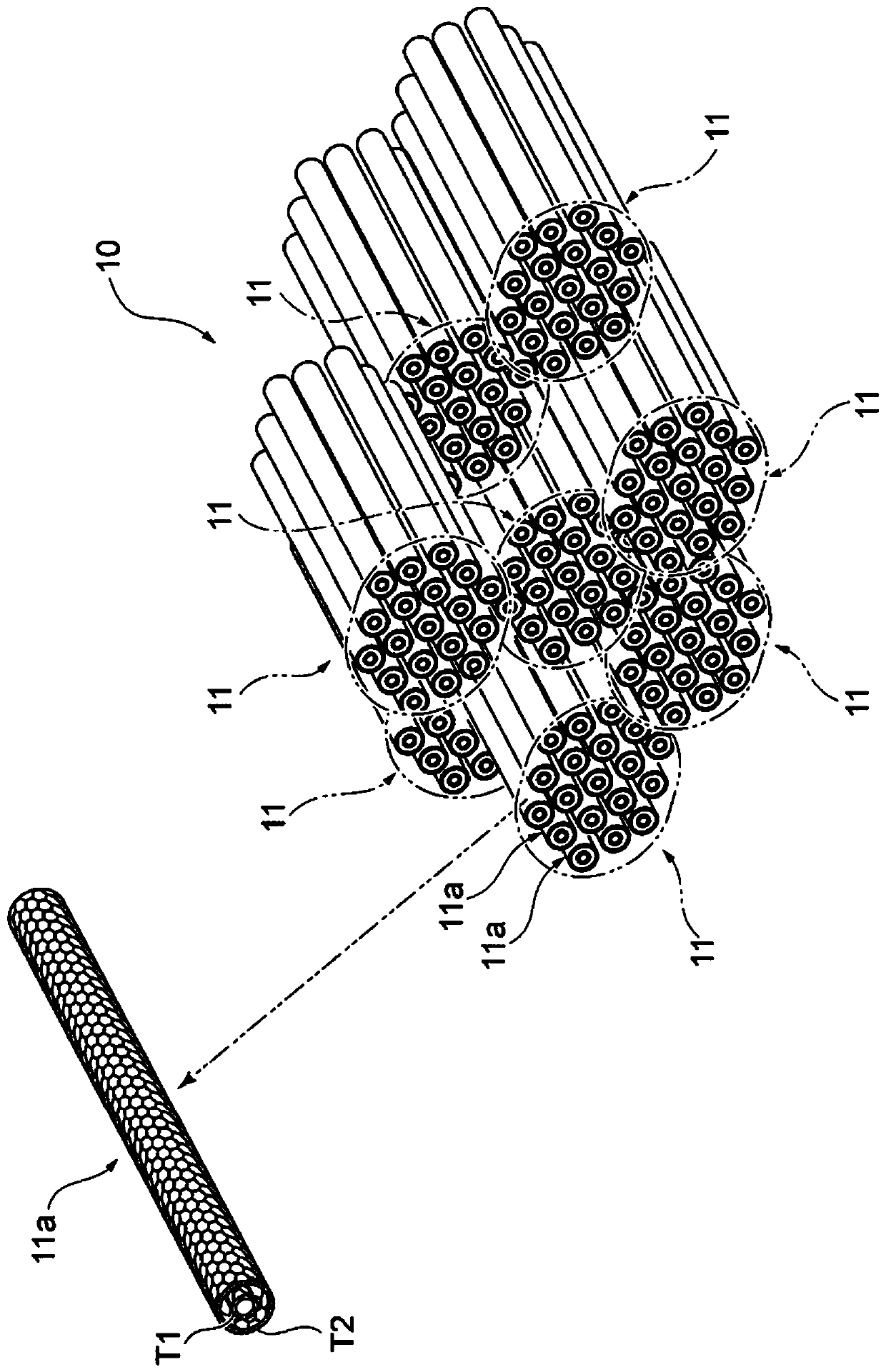

[0082] About the manufacturing method of CNT wire rod

[0083] First, the dry spinning method (Japanese Patent No. 5819888) or the method of wet spinning (Japanese Patent No. 5135620, Japanese Patent No. 5131571, Japanese Patent No. 5131571, Japanese Patent No. No. 5288359), so as to obtain a stranded wire composed of a plurality of CNT wires with an equivalent circle diameter of 5 mm.

[0084] About the method of coating the outer surface of the CNT wire with an insulating coating layer

[0085] Extrusion coating was carried out using the resins in Table 1 below to form a coating layer with an average thickness of 2.3 mm along the length direction on the outer surface of the CNT wire, thereby producing the following Table 1 used in Examples and Comparative Examples CNT-coated wires.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com