Cement-stabilizing layer material of regenerated fiber-reinforced building solid waste recycled fine aggregate and preparation method of cement-stabilizing layer material

A technology of solid waste and recycled fine aggregate, which is applied in the direction of solid waste management, sustainable waste treatment, and climate sustainability, and can solve problems such as environmental pollution, waste of construction solid waste regeneration resources, and high processing costs. Achieve high compressive strength and enhance the effect of use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

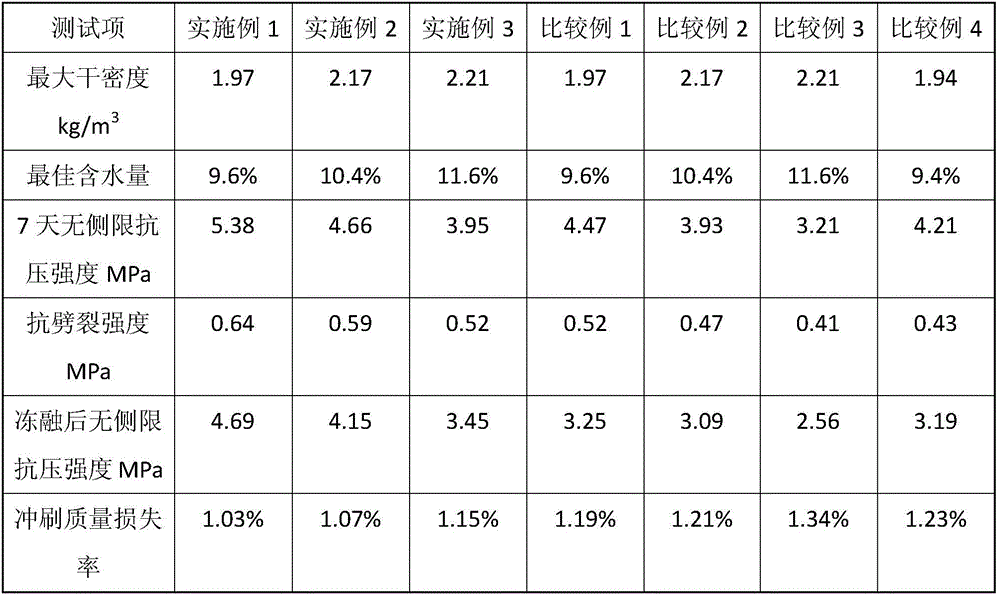

Examples

Embodiment 1

[0044] This embodiment relates to a water-stabilizing layer material of fiber-reinforced construction solid waste regenerated fine aggregate, which is composed of 94.5% mass fraction of construction solid waste regenerated fine aggregate (wherein the mass of 1# material and 2# material ratio of 3.26:6.74) and 5.5% of P.O 42.5 cement, mixed with 3‰ of recycled woven bag fiber and 9.6% of water relative to the sum of the above two raw materials, wherein the length of the recycled woven bag fiber is 15~ 20mm, equivalent diameter 35-50μm, tensile strength ≥ 826MPa.

[0045]This embodiment also relates to a method for preparing a water-stabilizing layer material of fiber-reinforced construction solid waste regenerated fine aggregate, the method comprising the following steps:

[0046] Add 94.5% mass fraction of construction solid waste regenerated fine aggregate (the mass ratio of 1# material to 2# material is 3.26:6.74) and 5.5% mass fraction of P.O 42.5 cement into the forced mix...

Embodiment 2

[0048] This embodiment relates to a water-stabilizing layer material of fiber-reinforced construction solid waste regenerated fine aggregate, which is composed of 95.5% mass fraction of construction solid waste regenerated fine aggregate (wherein the mass of 1# material and 2# material The ratio is 4.35:5.65) and 4.5% of P.O 32.5 cement, and externally mixed with 1‰ of recycled glass fiber and 10.4% of water relative to the sum of the above two raw materials, wherein the length of recycled glass fiber is 6-15mm, The equivalent diameter is 15-35μm, and the tensile strength is ≥950MPa.

[0049] This embodiment also relates to a method for preparing a water-stabilizing layer material of fiber-reinforced construction solid waste regenerated fine aggregate, the method comprising the following steps:

[0050] Add 95.5% mass fraction of construction solid waste regenerated fine aggregate (the mass ratio of 1# material to 2# material is 4.35:5.65) and 4.5% mass fraction of P.O 32.5 ce...

Embodiment 3

[0052] This embodiment relates to a water-stabilizing layer material of fiber-reinforced construction solid waste regenerated fine aggregate, the material is composed of 97% mass fraction of construction solid waste regenerated fine aggregate (wherein the quality of 1# material and 2# material The ratio is 6.86:3.14) and 3% of P.O 42.5 cement with a mass fraction of 2‰ of recycled woven bag fiber and 12.5% of water relative to the sum of the above two raw materials, wherein the length of the recycled woven bag fiber is 15 ~20mm, equivalent diameter 35~50μm, tensile strength ≥826MPa.

[0053] This embodiment also relates to a method for preparing a water-stabilizing layer material of fiber-reinforced construction solid waste regenerated fine aggregate, the method comprising the following steps:

[0054] Add 97% mass fraction of construction solid waste regenerated fine aggregate (the mass ratio of 1# material to 2# material is 6.86:3.14) and 3% mass fraction of P.O 42.5 cemen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com