An anti-break telescopic feeder for vehicle loading

A feeder and anti-shattering technology, which is applied in the direction of conveyor, loading/unloading, transportation and packaging, etc., can solve the problems that affect the profit of the enterprise, large dust, high lump coal limit rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail below in conjunction with accompanying drawing:

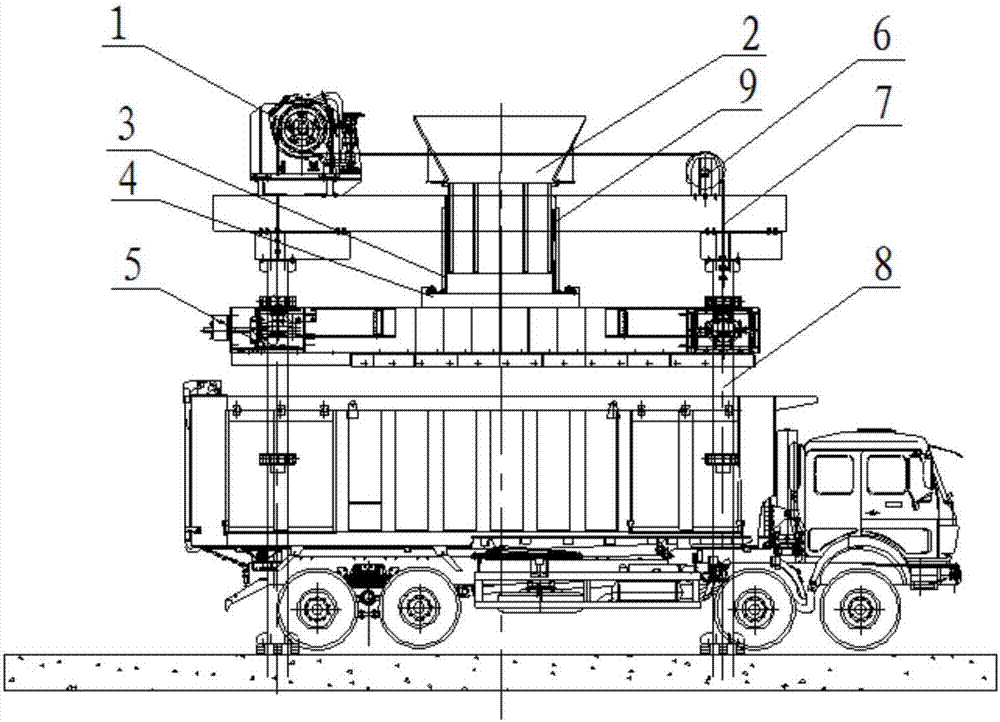

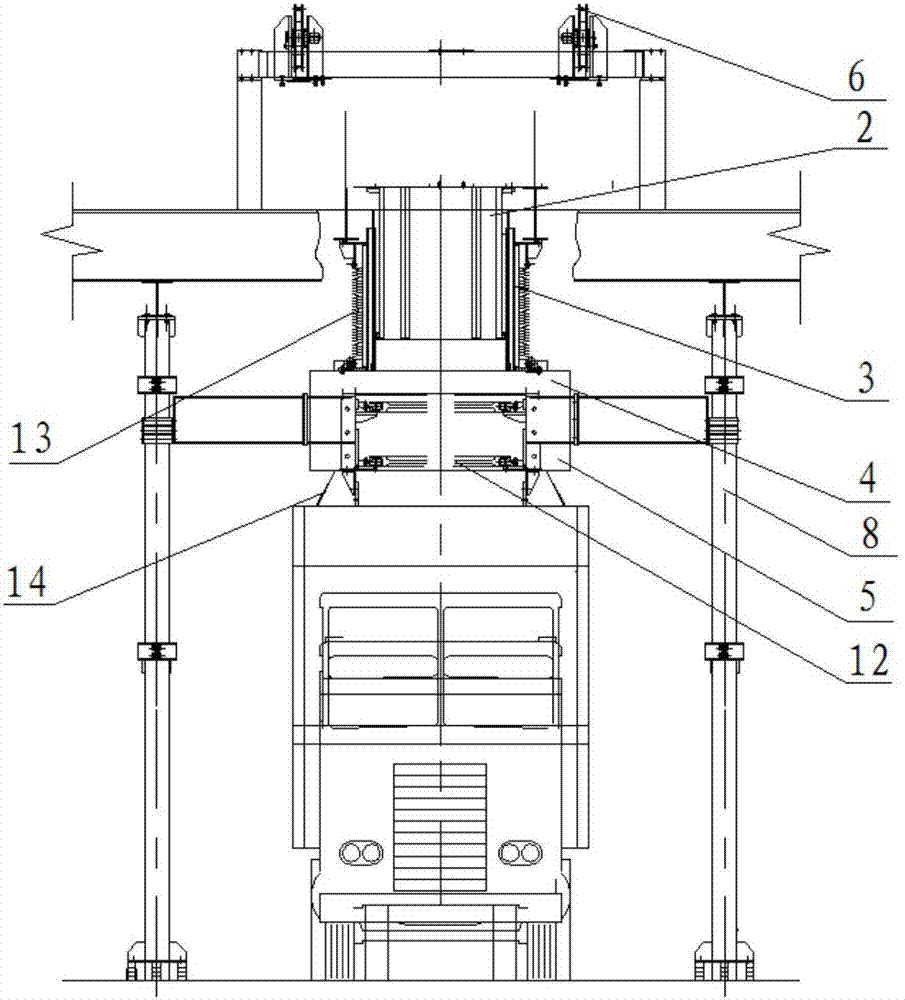

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the Patent Office of the present invention discloses an anti-breakage telescopic feeder for loading vehicles, including a discharge device, and a flat material device and a support device are sequentially arranged below the discharge device;

[0027] The unloading device includes a chute section and a discharge gate arranged below the chute section. The chute section includes an internal fixed chute 2 and an external movable telescopic chute 3; Type structure chute; The external movable telescopic chute 3 slides up and down in the dovetail groove type slide rail that is provided with on the internal fixed chute 2.

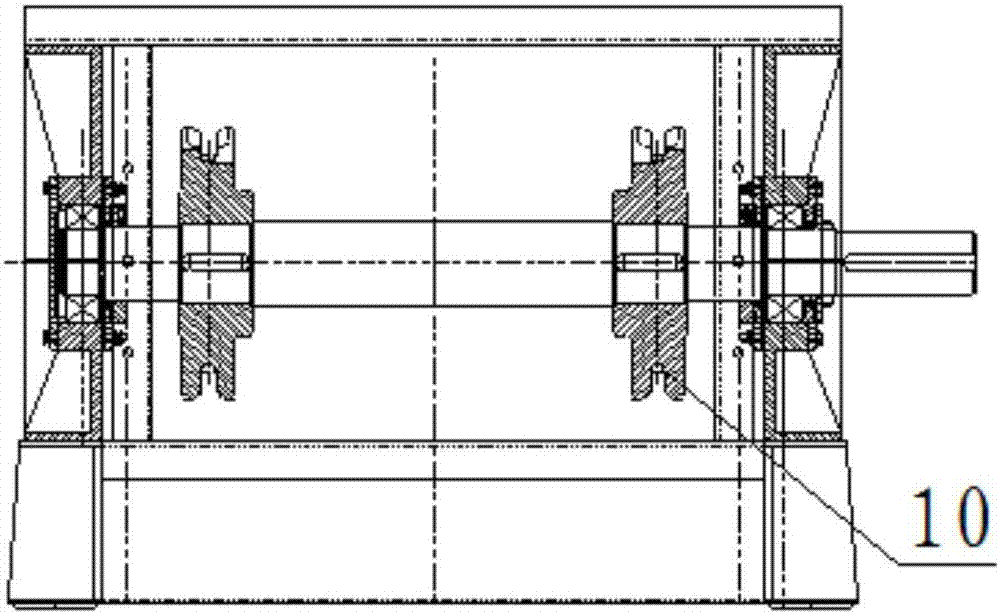

[0028] The leveling device includes a coal scraper 5, and the scraper 5 includes a scraper 12, and the scraper 12 passes through the scraper chain 11 and the head sprocket 10 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com