Multifunctional liquid sampling and storing steel cylinder of novel sealing structure

A sealed structure, liquid sampling technology, applied in the field of storage and testing of toxic and harmful liquids, can solve the problems of inability to fill nitrogen to maintain pressure, inability to achieve airtight sampling, inability to effectively prevent components from entering the bottle, etc., and achieve the effect of solving poor sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

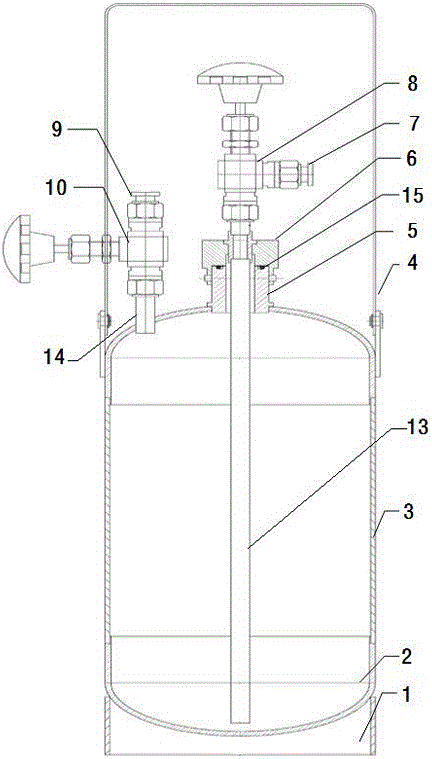

[0028] 1. Bottle design

[0029] According to the specifications of the stainless steel pipe, select Φ133×2, S31603 stainless steel cylinder, the length of the cylinder section is 83mm, the head is 35mm, and the total volume of the bottle body 3 is 2.2L.

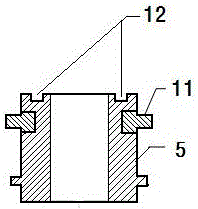

[0030] 2. Pipeline and interface design

[0031] The liquid pipe 13 and the liquid pipe interface 7, the gas pipe 14 and the gas pipe interface 9 all adopt the form of Φ14×1.5, 60° threaded joints. Both the liquid pipe interface 7 and the gas pipe interface 9 are equipped with a sealing cover. The distance between the liquid pipe 13 and the gas pipe 14 is appropriate, which is convenient for valve disassembly and sampling operation.

[0032] The liquid pipe 13 adopts ø8×2, and the center point coincides with the center point of the bottle body 3 .

[0033] The gas pipe 14 adopts ø8×2, the interface is M14×1.5, a 60-degree bell mouth, and the center point is 40mm away from the center point of the tank body.

[0034] Both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com