A kind of thermite welding crucible forming mold

A technology for forming molds and aluminothermic welding, applied in the directions of molds, ceramic forming cores, ceramic forming mandrels, etc., can solve the problems affecting the welding quality of aluminothermic welding, unfavorable aluminothermic welding, leakage of molten steel, etc., and achieve the effect of sand injection molding Good, ensure the filling ability, prevent the effect of blocking the exhaust hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

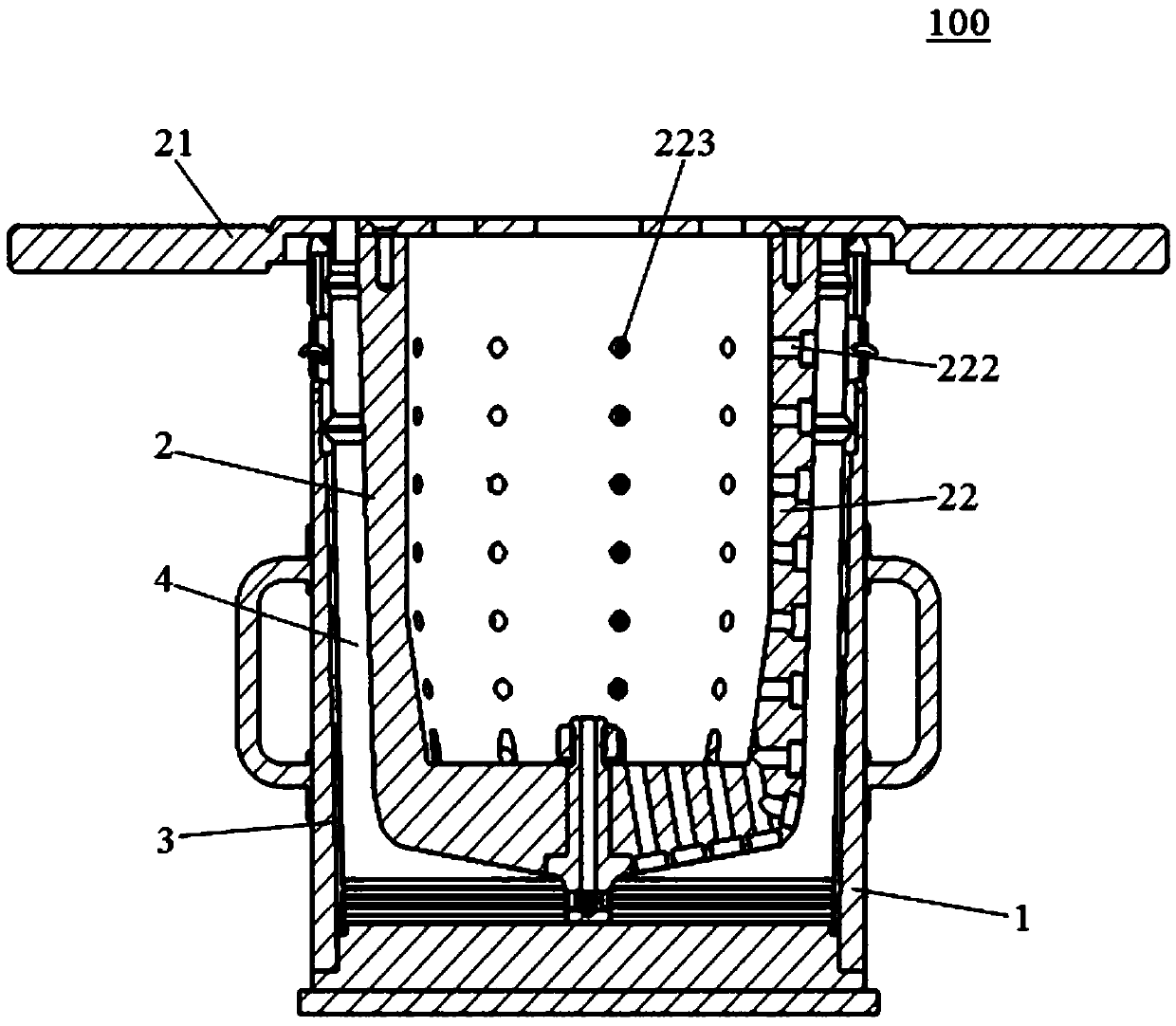

[0030] Please refer to Figure 1-Figure 5 This embodiment is the aluminothermic crucible forming mold 100, which includes an outer mold 1 in which a first cavity 11 is formed, and an inner mold 2 partially housed in the first cavity 11. The first cavity 11 contains a container barrel 3 close to the inner wall surface of the first cavity 11. The inner mold 2 and the container barrel 3 constitute a crucible core shooting cavity 4.

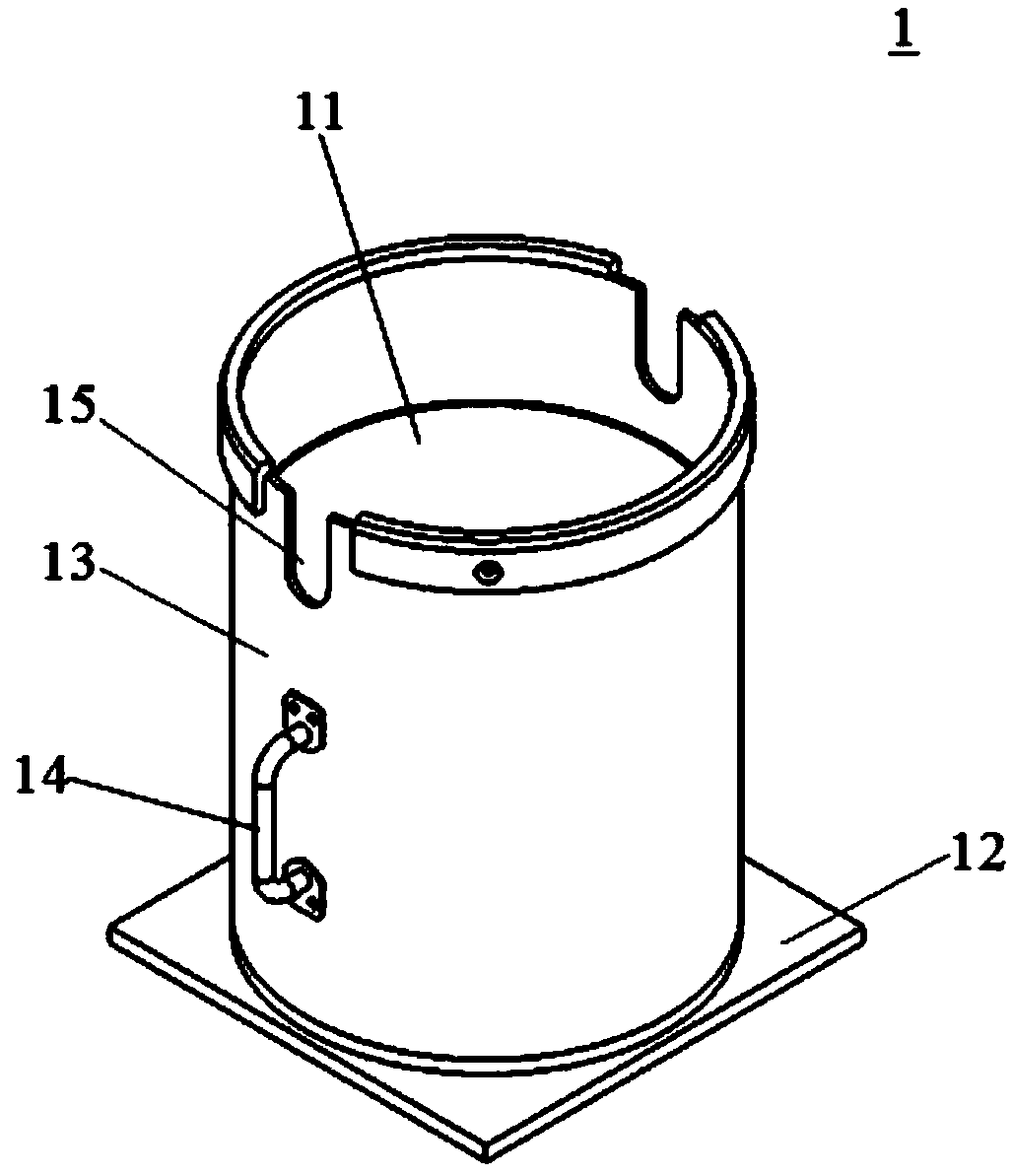

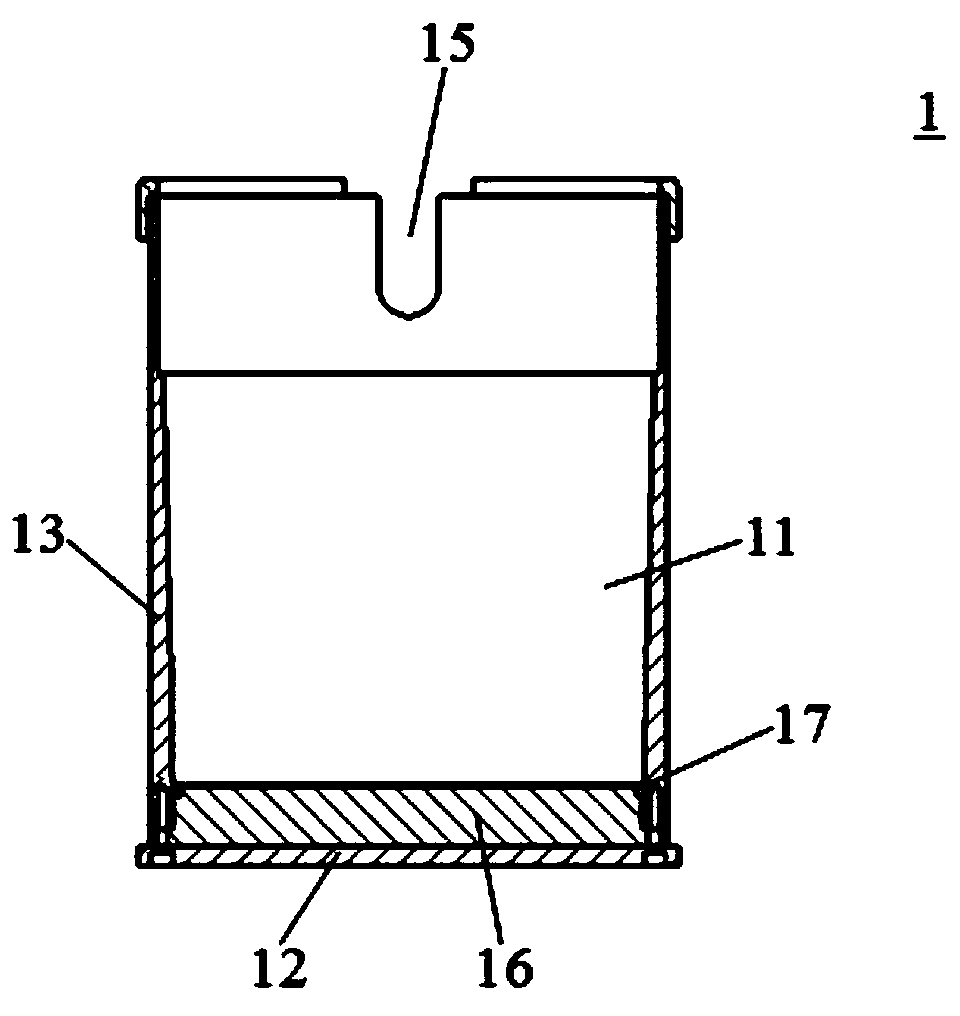

[0031] The outer mold 1 includes a base 12, a cylinder 13 fixed on the base 12, and a first handle 14 symmetrically fixed on the surface of the cylinder 13. U-shaped positioning openings 15 are symmetrically opened on the upper surface of the cylinder body 13, which have a positioning and guiding effect on the placement position of the container barrel 3. A circular boss 16 is provided in the middle of the base 12, and a positioning slot 17 is formed on the edge of the boss 16 and the inner wall surface of the cylinder 13, which is mainly used to clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com