Integrated heating wallboard and production method thereof

A technology that integrates heating walls and production methods, applied in heating methods, electric heating systems, household heating, etc., can solve the problems of low integration of heating wall panels, short service life, uneven heating, etc., and achieve reliable and durable structures and finished products The effect of stable quality and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, invention is further described:

[0031] The orientations described in the description of the invention, such as "upper", "lower", "left", "right", "front", "rear", etc., are all based on the orientation of the accompanying drawings, and are used to describe the relationship between each component. The purpose of the inter-relationship is not to indicate the unique or absolute positional relationship between the various components, but only to realize one of the implementation modes of the invention, and not to limit the implementation mode thereof.

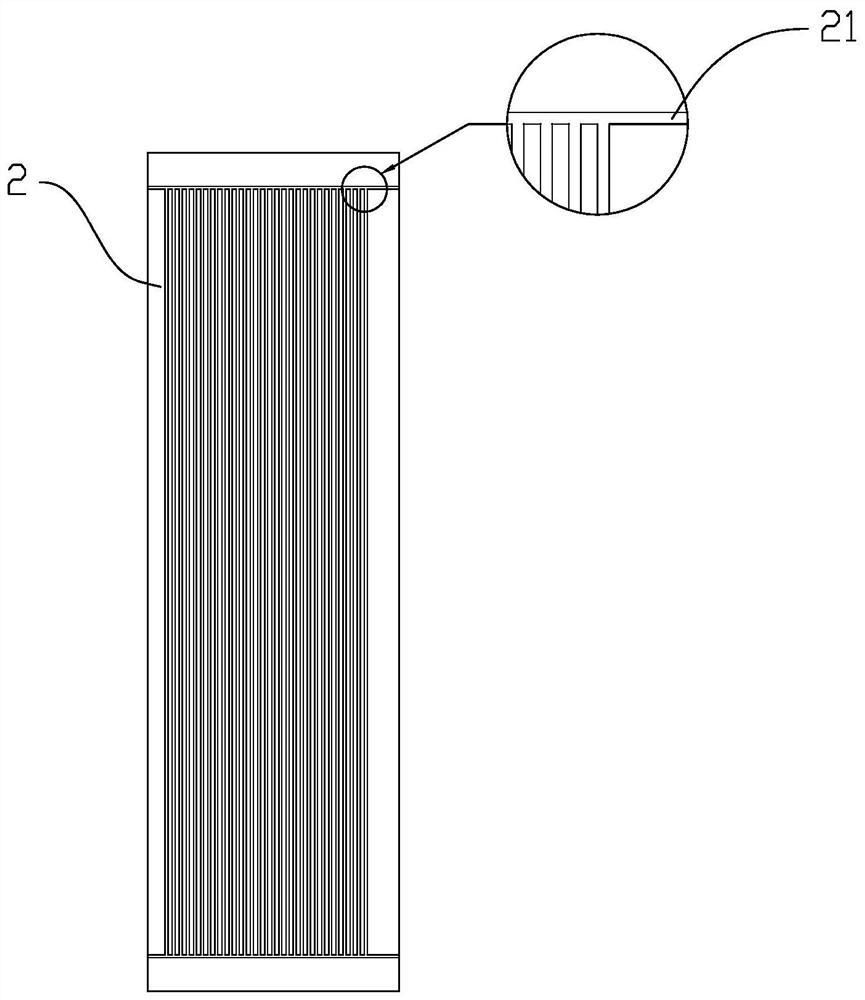

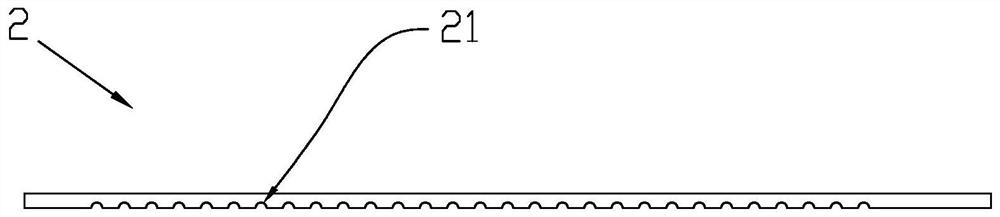

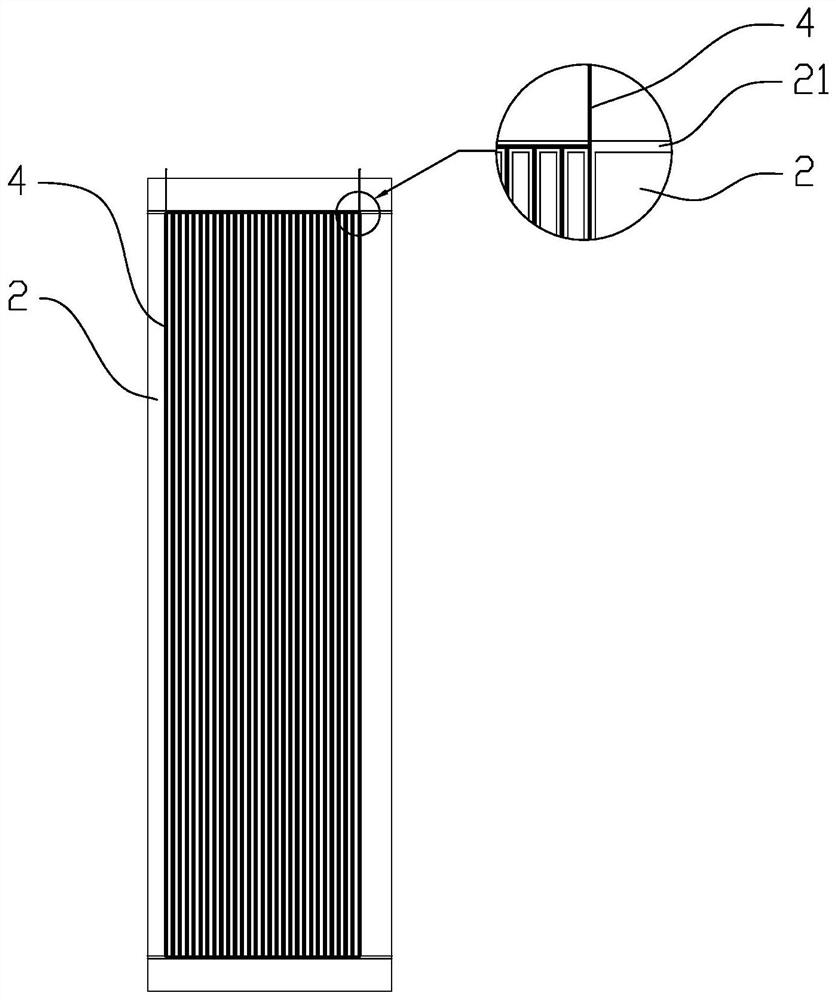

[0032] Such as Figure 5 As shown, an integrated heating wallboard includes a base plate 2, the upper surface of the base plate 2 is uniformly covered with tiles 3, and a plurality of embedded grooves 21 are opened on the base plate 2, The base plate 2 is provided with a heating wire 4 in the pre-embedded groove 21, and the lower surface of the base plate 2 is covered with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com