Slicer, feeding device thereof and slicing production line

A slicer and driving device technology, applied in the manufacture of thin wood chips, wood processing equipment, manufacturing tools, etc., can solve the problems of different lengths of materials, low production efficiency, complex structure, etc., to reduce the possibility of injury, reduce the Artificial input, the effect of ensuring personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

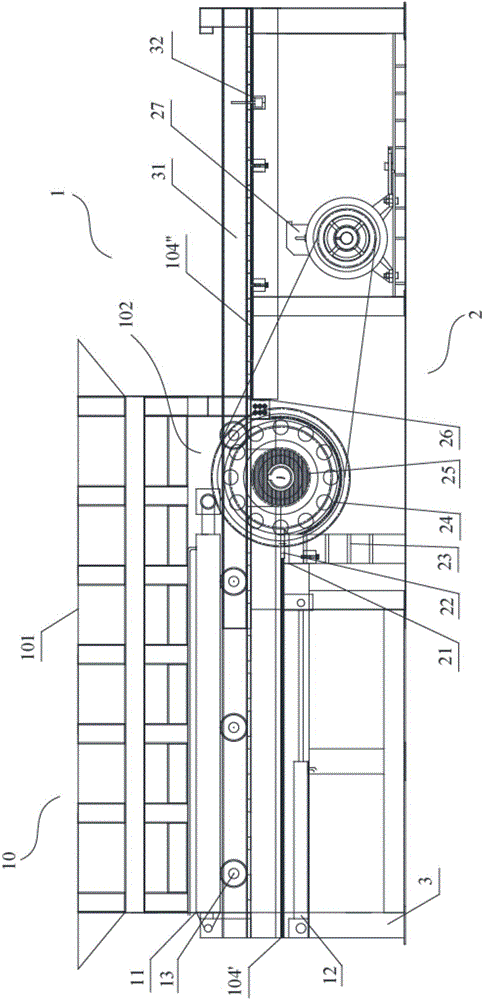

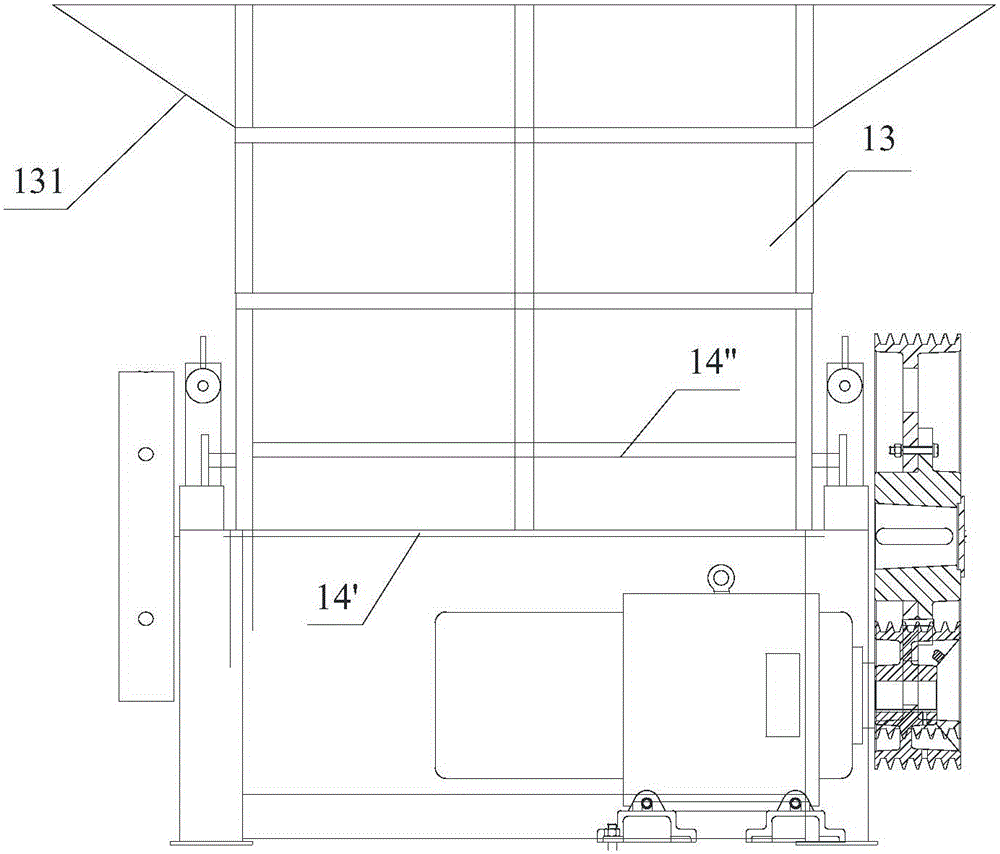

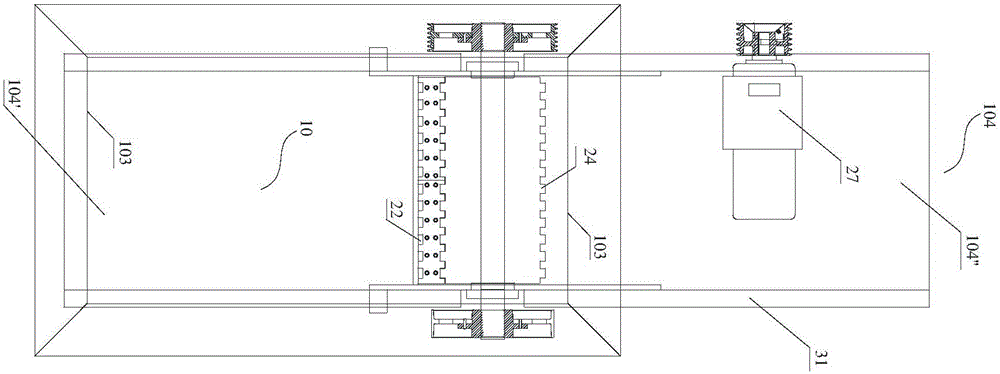

[0084] see figure 1 , figure 2 and image 3 , the slicer according to the first embodiment of the present invention, which includes: a frame 3 and a feeding mechanism 1 and a cutting mechanism 2 arranged on the frame 3 .

[0085] Wherein, the feeding mechanism 1 includes a moving bin 103 , a bottom plate 104 and a first driving device 11 . The base plate 104 and the mobile feed bin 103 encircle the material placement space, the base plate 104 is fixed on the frame 3, the material outlet 102 of the feed storage space is opened on the base plate 104, the material inlet 101 of the feed storage space is located at the mobile feed bin 103, and the mobile feed bin 103 is movably arranged on the bottom plate 104, and when moving on the bottom plate 104, the moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com