Brittle metal microspheres preparation method based on metal microspheres forming device

A brittle metal and forming device technology is applied to the preparation of brittle metal microspheres. By designing the field of metal microsphere forming devices, the problems of difficulty in manufacturing brittle metal microspheres, complicated mechanism and huge equipment can be solved, and the equipment is simple and the cost is achieved. Low, the effect of preventing metal oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

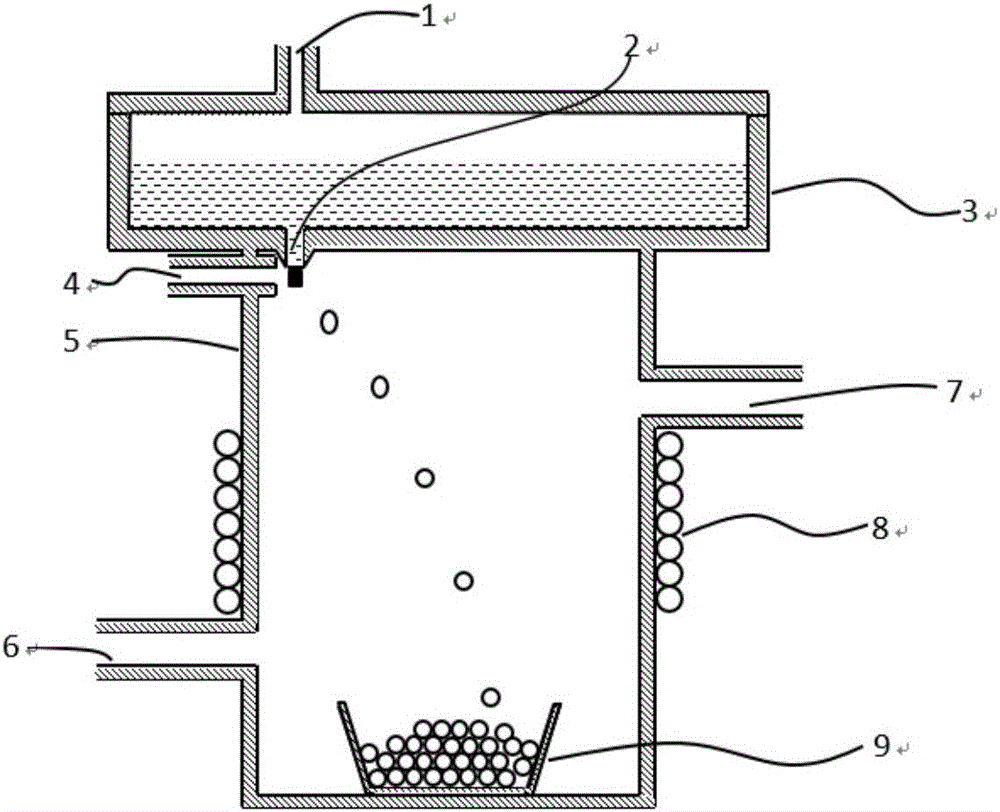

[0044] Once the compressed gas pressure, nozzle aperture and pulse gas frequency are determined according to the size of the metal ball to be manufactured (compressed gas pressure 0.5MPa, nozzle aperture 0.2mm, pulse gas frequency 50Hz), metal bismuth is placed in the melting chamber 3, heated Let it melt. The compressed gas is fed into the melting chamber 3 through the compressed gas inlet 1 , and the molten bismuth is ejected through the nozzle 2 .

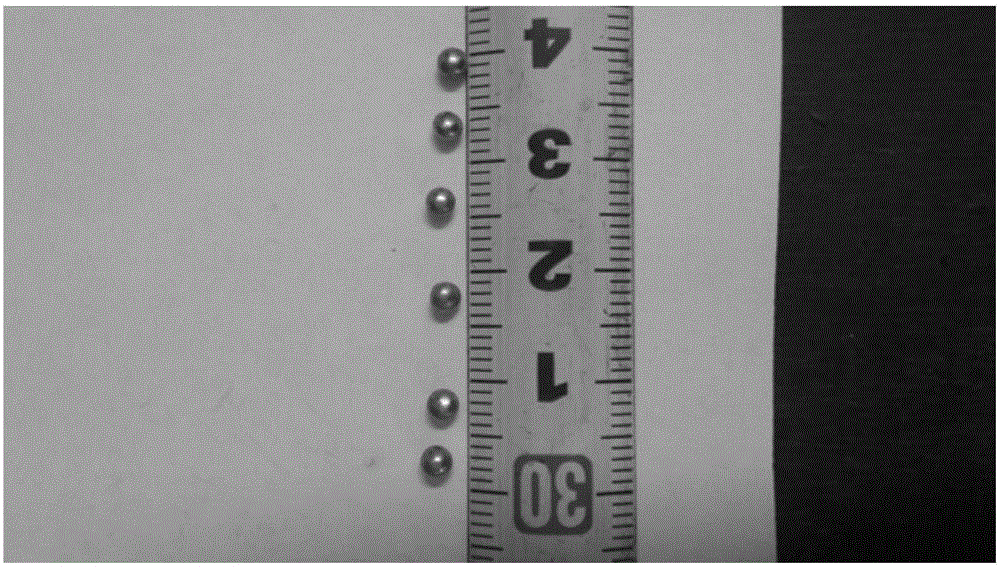

[0045]After the molten bismuth is ejected, it is blown away from the nozzle 2 by the pulse gas fed through the pulse gas inlet 4, causing it to fall, thereby forming bismuth droplets. During the falling process, the bismuth droplet transforms into an almost perfect spherical shape due to surface tension, and after passing through the area where the cooling unit 8 is located, it is cooled and solidified (specifically ensure that the temperature in this area is below 0° C.) to form a metal bismuth ball. Then, the metal bismuth ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com