Three-dimensional structure composite aerogel and preparation method thereof

A technology of composite airgel and three-dimensional structure, which is applied in the field of three-dimensional structure composite airgel and its preparation, can solve the problems of easy oxidation and dispersion of copper nanowires, improve electrical conductivity and mechanical properties, promote dispersion, and inhibit agglomeration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

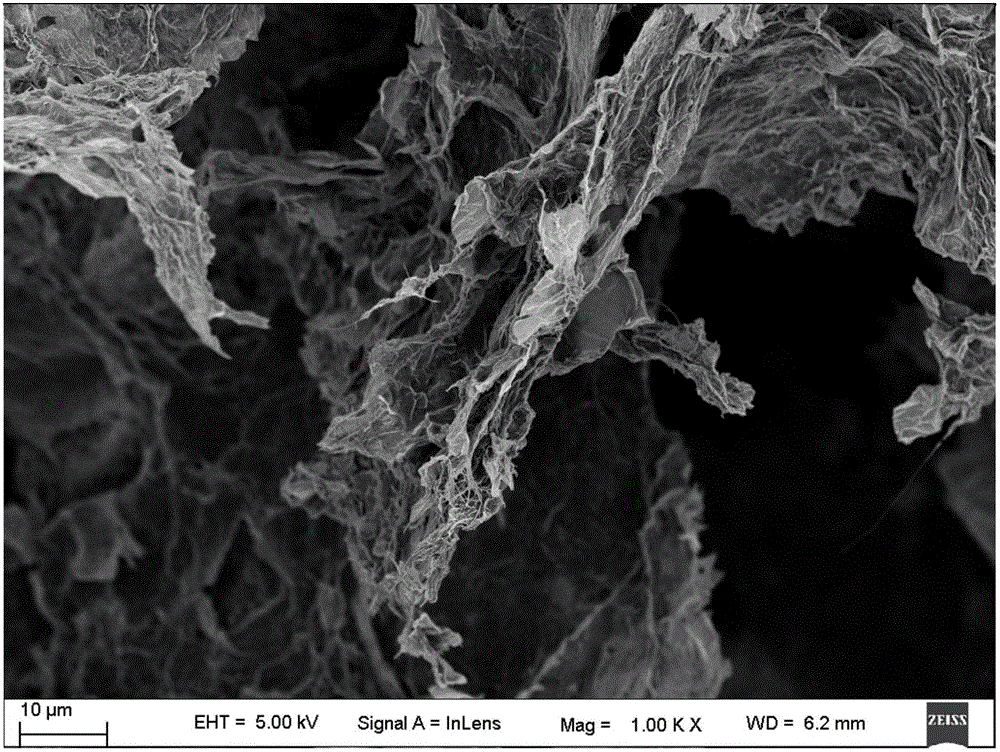

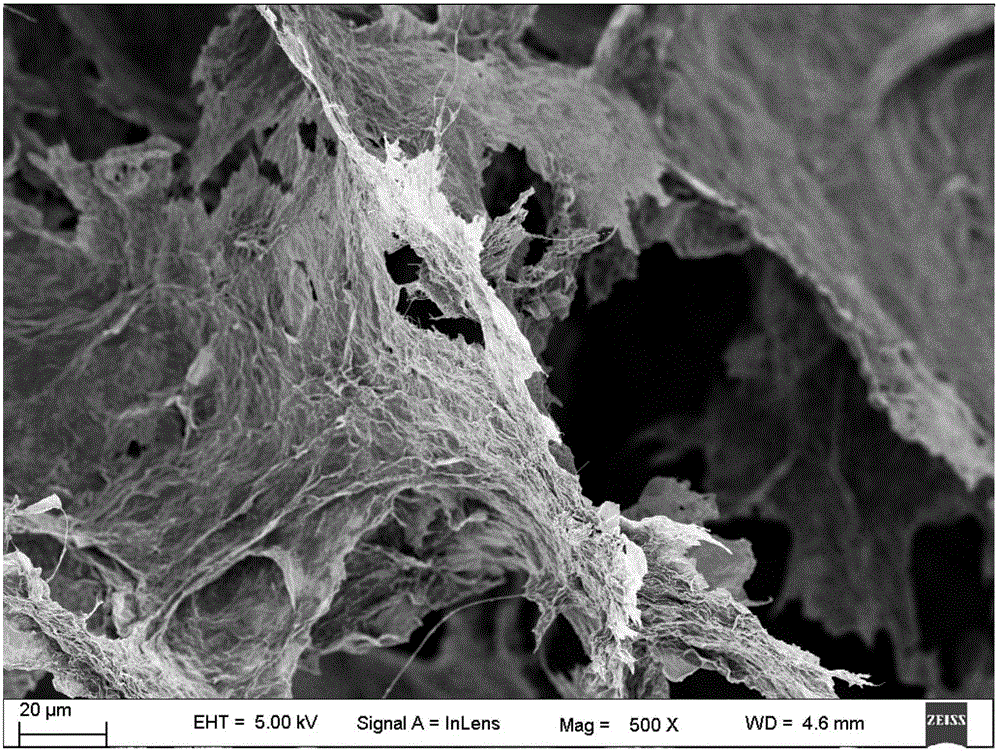

[0045] The preparation method of the copper nanowire-graphene oxide reduction co-assembled three-dimensional structure composite airgel of this embodiment comprises the following steps:

[0046] Weigh 100mg of ascorbic acid in a 20ml glass bottle, add 7.5ml of deionized water, stir to dissolve, add 80mg of copper nanowires and 2.5ml of graphene oxide aqueous solution, the concentration is 8mg / ml, which is the mass of copper nanowires and graphene oxide The ratio is 4:1, ultrasonic 30min, to obtain a mixed solution;

[0047] The above mixed solution was heated to 50° C., kept for 16 hours, and cooled to room temperature to obtain a copper nanowire-graphene three-dimensional structure composite hydrogel. The copper nanowire-graphene three-dimensional structure composite hydrogel was removed from excess water, and then Add deionized water to wash, remove excess water after standing for 12 hours, and repeat several times;

[0048] The washed copper nanowire-graphene three-dimensi...

Embodiment 2

[0051] On the basis of Example 1, the difference between the preparation method of the copper nanowire-graphene co-assembled three-dimensional structure composite airgel of this example and Example 1 is that the quality of the copper nanowire is 40 mg, that is, the copper nanowire and the The mass ratio of graphene oxide is 2:1.

[0052] Other steps of the preparation method of the copper nanowire-graphene co-assembled three-dimensional structure composite airgel in this embodiment are the same as those in Embodiment 1.

Embodiment 3

[0054] On the basis of Example 1, on the basis of Example 1, the preparation method of the copper nanowire-graphene co-assembled three-dimensional structure composite airgel in this example differs from Example 1 in that the quality of the copper nanowires 60 mg, that is, the mass ratio of copper nanowires to graphene oxide is 3:1.

[0055] Other steps of the preparation method of the copper nanowire-graphene co-assembled three-dimensional structure composite airgel in this embodiment are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com