Horizontal continuous casting crystallizer of cast iron and preparing method of cast iron proximate matter

A technology for casting crystallizers and crystallizers, which is applied in the field of preparing cast iron profiles and cast iron horizontal continuous casting crystallizers. It can solve the problems of scars on cast iron profiles, and achieve the effects of small machining allowance, high production efficiency, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

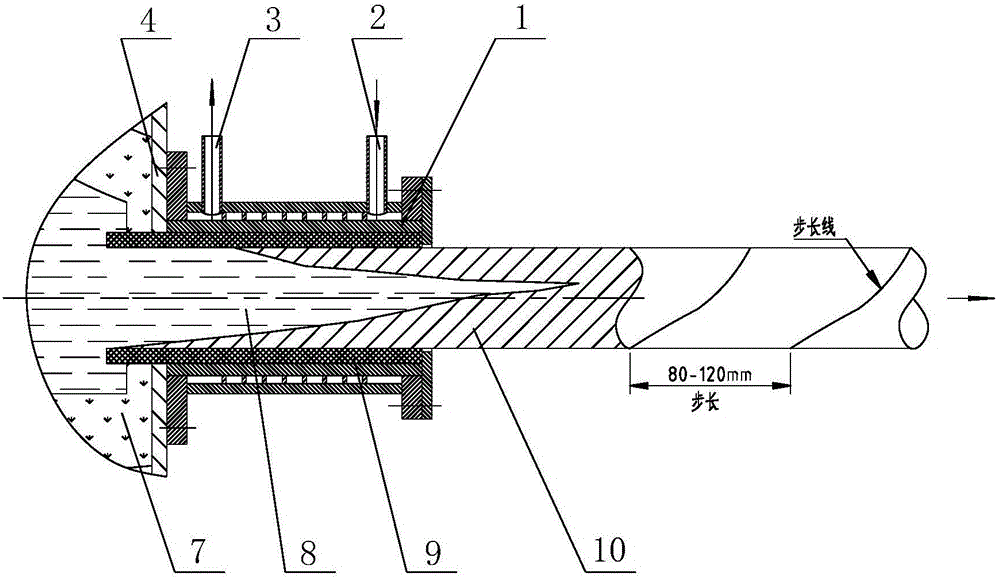

[0049] The Φ80mm gray cast iron profile is cast horizontally and continuously with the lower nozzle type isolation ring crystallizer.

[0050] The drain type isolation ring crystallizer adopts Figure 5 Graphite molds for the first row, and the spacer ring for the drain Figure 5 The first one in the first row, that is, the one with a semicircular cross-section. The inner hole size of the graphite mold 9 is Φ80mm. After pouring the gray iron molten iron inoculated with floating silicon into the holding furnace, start to continuously cast Φ80mm gray cast iron profiles in a double-stream horizontal continuous casting with the "pull-stop-pull" process. tons / hour.

Embodiment 2

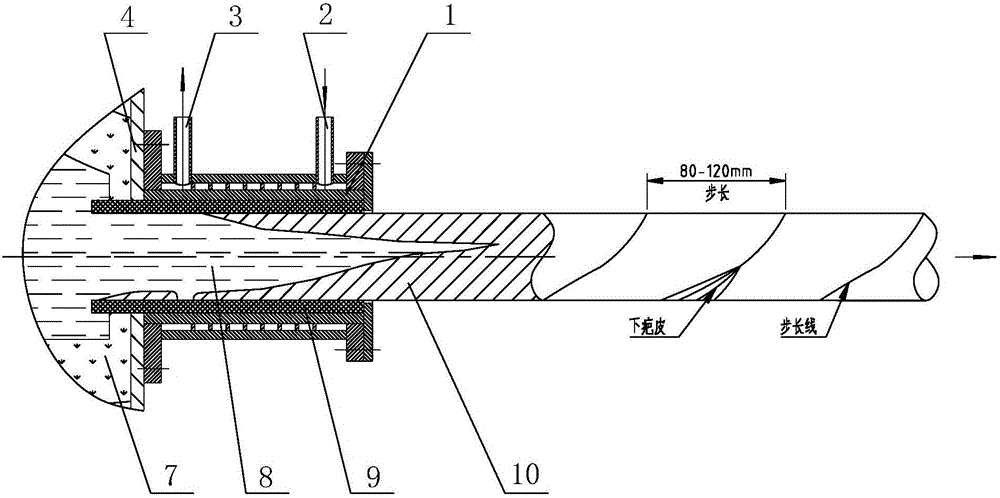

[0052] The Φ180mm ductile iron profile is cast horizontally and continuously with the nozzle-type spacer ring mold.

[0053] The drain type isolation ring crystallizer adopts Figure 5 Graphite molds for the first row, and the spacer ring for the drain Figure 5 The third in the first row, that is, the semi-circular section. The inner hole size of the graphite mold 9 is Φ180mm. After the spheroidized molten iron is inoculated with floating silicon and poured into the holding furnace, the "pull-stop-pull" process is used to continuously cast Φ180mm ductile iron profiles horizontally in a single stream. Production 2.5 tons / hour.

Embodiment 3

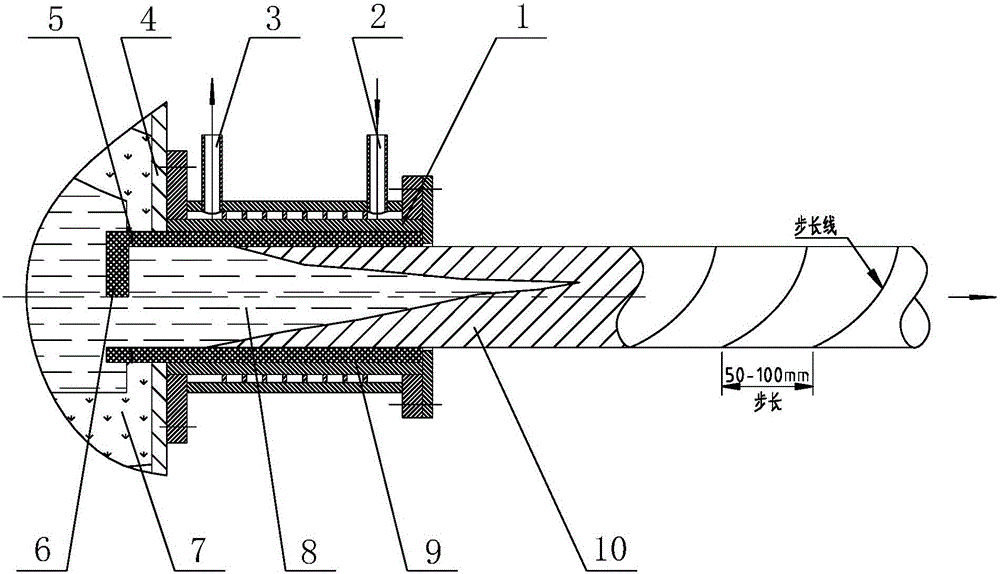

[0055] The horizontal continuous casting of nodular iron profiles with a regular hexagonal cross-section of 120 mm in opposite sides is adopted with the nozzle-type spacer ring crystallizer.

[0056] The drain type isolation ring crystallizer adopts Figure 5 Graphite mold for the second row, the drain type spacer ring adopts Figure 5 The second one in the second row, that is, the intermediate section. The inner hole size of the graphite mold 9 is a regular hexagon with opposite sides of 120 mm. After the spheroidized molten iron is inoculated with floating silicon and poured into the holding furnace, the "pull-stop-pull" process is used to continuously cast ductile iron profiles with a regular hexagonal cross-section of 120 mm across sides, and the step length of the cast iron profiles is controlled at 70-90mm, single shift production 2 tons / hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Step size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com