A synergistic removal agent for flue gas multi-pollutants used in dense phase dry tower process

A technology for removing agents and pollutants, applied in gas treatment, air quality improvement, membrane technology, etc., can solve the problems of high price and low efficiency, and achieve the effects of reducing preparation costs, reducing costs, and enhancing adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

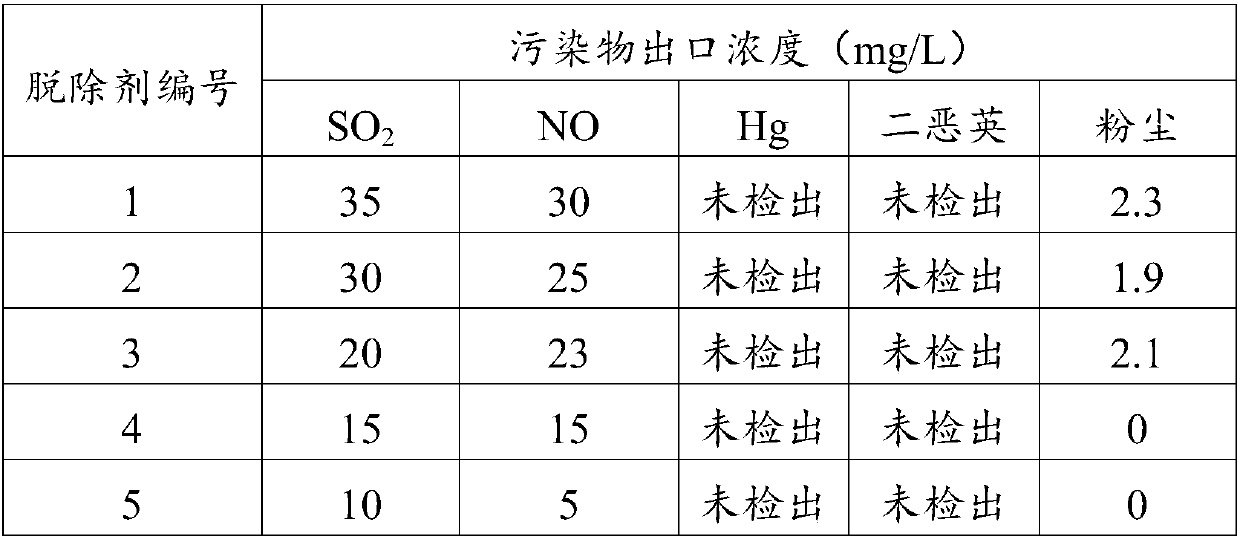

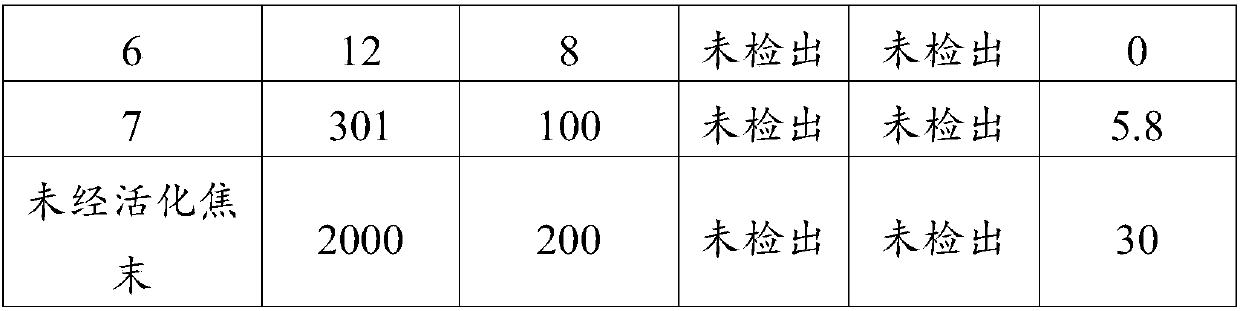

Examples

Embodiment 1

[0021] First, take 10 kg of coke powder with a particle size of 3 mm, roast it in a rotary roasting furnace at 200 ° C, 50 rpm for 30 minutes, then open the furnace door, cool it for 1 hour, and the temperature of the coke powder will drop to 98 ° C. Then close the furnace door again, and in the rotary roaster, pass into the nitrogen with a purity of 99.99%. When the nitrogen content in the rotary roaster reaches more than 99%, stop nitrogen filling, and close the rotary roaster door. At this time, the temperature in the furnace is displayed as 90°C, adjust the rotation speed to 200r / min, and start the surface treatment of the coke powder. After 1 hour of treatment in a nitrogen environment, continue to raise the temperature of the rotary roaster to 500°C, at a rotation speed of 50r / min Calcined in a rotary roaster for 30min. After closing the roasting furnace for 1 hour, open the furnace door, and after another 1 hour, the temperature in the furnace dropped to 102° C., and th...

Embodiment 2

[0023] First, take 10 kg of coke powder with a particle size of 2 mm, roast it in a rotary roasting furnace at 200 ° C, 50 rpm for 30 minutes, then open the furnace door, and cool it for 1 hour, and the temperature of the coke powder will drop to 98 ° C. Then close the furnace door again, and in the rotary roaster, pass into the nitrogen with a purity of 99.99%. When the nitrogen content in the rotary roaster reaches more than 99%, stop nitrogen filling, and close the rotary roaster door. At this time, the temperature in the furnace is displayed as 90°C, adjust the speed to 200r / min, and start the surface treatment of the coke powder. After 1 hour of treatment in a nitrogen environment, continue to raise the temperature of the roasting furnace to 500°C. Calcined in a rotary roaster for 30 minutes. After closing the roasting furnace for 1 hour, open the furnace door, and after another 1 hour, the temperature in the furnace dropped to 102° C., and the steps of filling nitrogen g...

Embodiment 3

[0025] First, take 10 kg of coke powder with a particle size of 2 mm, roast it in a rotary roasting furnace at 200 °C and 100 rpm for 60 minutes, then open the furnace door, and cool it for 1 hour, and the temperature of the coke powder will drop to 98 °C. Then close the furnace door again, and in the rotary roaster, pass into the nitrogen with a purity of 99.99%. When the nitrogen content in the rotary roaster reaches more than 99%, stop nitrogen filling, and close the rotary roaster door. At this time, the temperature in the furnace is displayed as 90°C, adjust the speed to 200r / min, and start the surface treatment of the coke powder. After 1 hour of treatment in a nitrogen environment, continue to raise the temperature of the roasting furnace to 500°C. Calcined in a rotary roaster for 60 minutes. After closing the roasting furnace for 1 hour, open the furnace door, and after another 1 hour, the temperature in the furnace dropped to 102° C., and the steps of filling nitrogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com