Carbon nanosphere preparation as well as preparation method and anti-helicobacter pylori infection experiment method thereof

A technology against Helicobacter pylori and Helicobacter pylori, which is applied in antibacterial drugs, material inspection products, carbon active ingredients, etc., can solve the problems of high infection recurrence rate, aggravated drug adverse reactions, and increased drug dosage. Achieving powerful anti-Helicobacter pylori effect, ensuring high stability, and low dose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] As a specific embodiment, the preparation method of carbon nanosphere preparation comprises the following steps:

[0048] 1. Using graphene as the raw material to process and prepare carbon nanospheres;

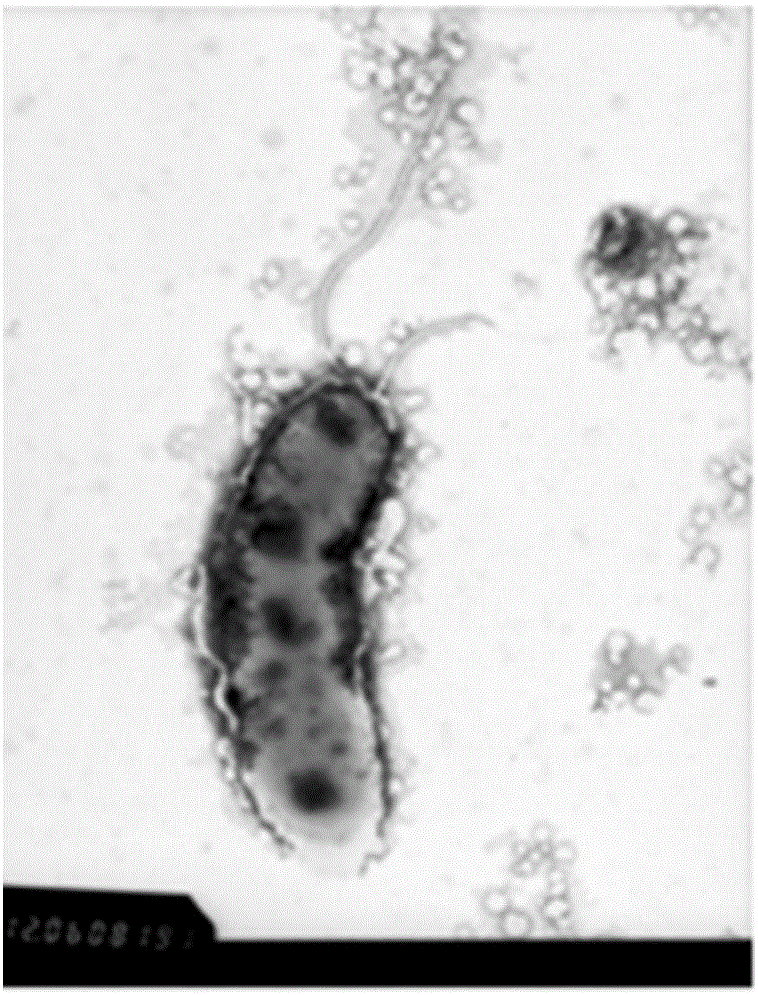

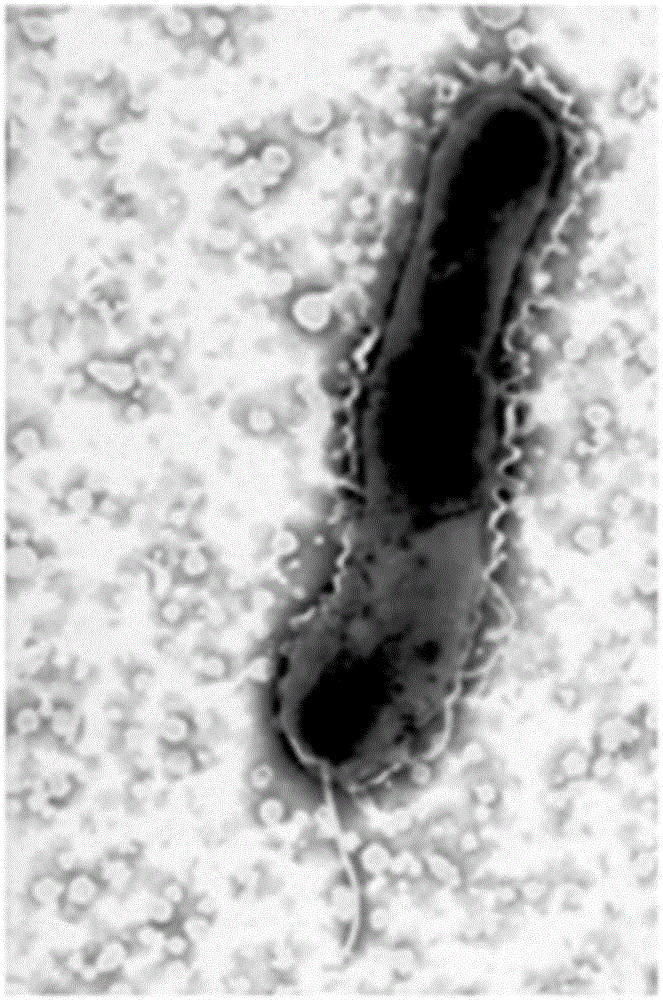

[0049] 2. Use transmission electron microscopy to screen carbon nanospheres whose particle size meets the requirements, wherein carbon nanospheres with a particle size of 5-30 nm account for more than 95%; carbon nanospheres are dispersed in a single spherical shape;

[0050] 3. According to the concentration requirements, weigh the carbon nanospheres screened in step 2 and deionized water respectively, and set aside;

[0051] 4. Mix and disperse the carbon nanospheres obtained in step 3 and deionized water;

[0052] 5. Stir the mixed liquid obtained by mixing in step 4, wherein the stirring time is 10-20 minutes, and the stirring speed is 60-80 r / min;

[0053] 6. Ultrasonic treatment is performed on the mixed solution after the stirring treatment in step five, where...

Embodiment 1

[0058] Example 1: Preparation of carbon nanospheres and deionized water.

[0059] Graphene is used as a raw material to process and prepare carbon nanospheres, and the carbon nanospheres with a particle size of 5-30 nm are screened under a transmission electron microscope for future use. It should be ensured that carbon nanospheres with a particle size of 5-30 nm account for more than 95% of the total amount.

[0060] Prepare deionized water and set aside.

Embodiment 2

[0061] Example 2: Preparation of 1.0% carbon nanosphere preparation.

[0062] According to the concentration requirement of 1.0%, a certain amount of carbon nanospheres and deionized water were mixed and dispersed, and stirred for 20 minutes, wherein the stirring speed was 80 r / min.

[0063] Ultrasonic treatment was performed on the stirred mixed solution, wherein the whole ultrasonic time was set to 20 minutes, the single ultrasonic time was set to 3 seconds, the interval time was set to 3 seconds, and the ultrasonic intensity was set to 100w (ultrasound in a low-temperature water bath).

[0064] The pH value of the mixed solution after ultrasonication is adjusted with sodium bicarbonate-sodium carbonate buffer solution, and the final pH value of the mixed solution is adjusted to 7.6, so as to obtain a carbon nanosphere preparation that meets the requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com