Method and device for detecting gas concentration

A technology of gas concentration and detection method, applied in liquid/vacuum measurement for liquid tightness, by detecting the appearance of fluid at the leak point, etc., can solve the problems of low efficiency, low detection accuracy, and inability to guarantee work quality, etc. Achieve low cost and no manual intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A gas concentration detection method described in the present invention utilizes the principle that the diffusion speed of one gas in another gas is inversely proportional to the pressure of the surrounding gas, that is, the characteristic that the tracer gas diffuses faster in a vacuum state , adopting the scientific and reasonable combination of the advantages of vacuum box-type gas leak detection technology and atmospheric suction gun-type leak detection technology, it can not only realize low-cost and fast detection of gas concentration and gas leakage, but also realize automatic detection at the same time No human intervention is required, and leaks can be approximated.

[0032] The gas concentration detection method of the present invention comprises the following steps:

[0033] S1: Place the workpiece to be inspected in a confined space;

[0034] S2: In the confined space, a number of gas suction points are distributed outside the workpiece to be inspected, and...

Embodiment 2

[0043] Such as image 3 with 4As shown, a gas concentration detection device according to the present invention utilizes the principle that the diffusion speed of one gas in another gas is inversely proportional to the pressure of the surrounding gas, that is, the diffusion speed of the tracer gas is faster at low pressure. It adopts the scientific and reasonable combination of the advantages of vacuum box type gas leak detection technology and atmospheric suction gun type leak detection technology, which can realize low-cost and fast detection of gas concentration and gas leakage, and at the same time realize automatic Detect without manual intervention, but also provide approximate location of leaks.

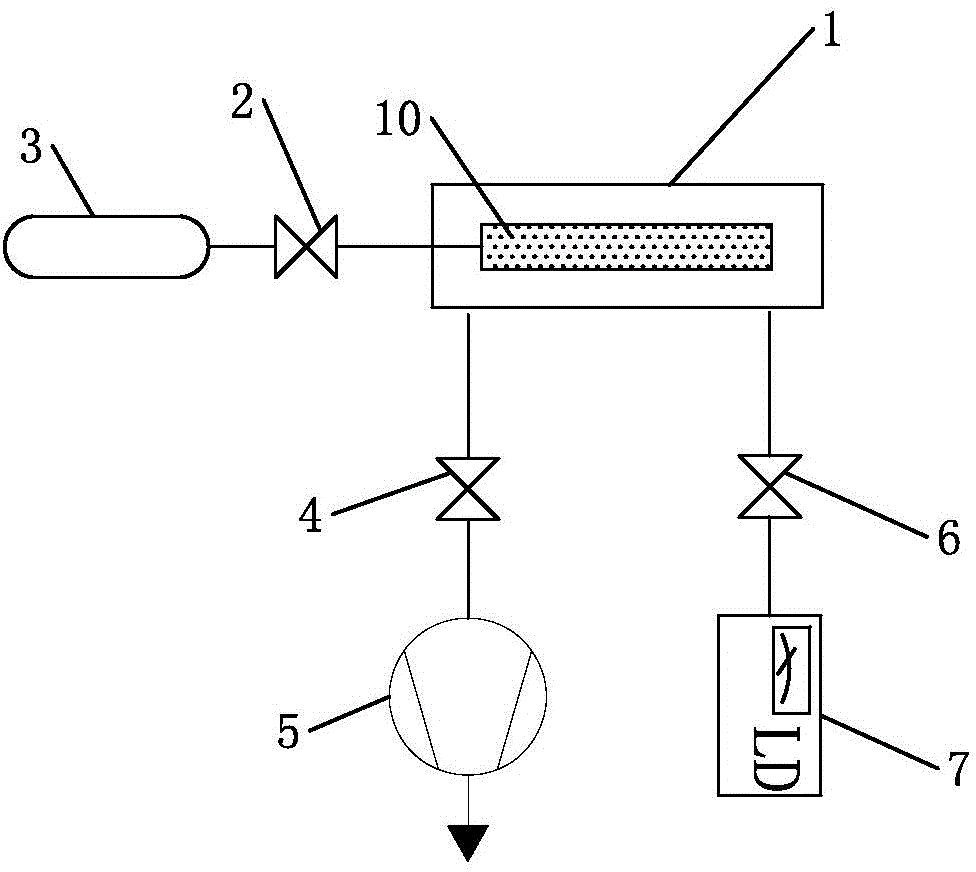

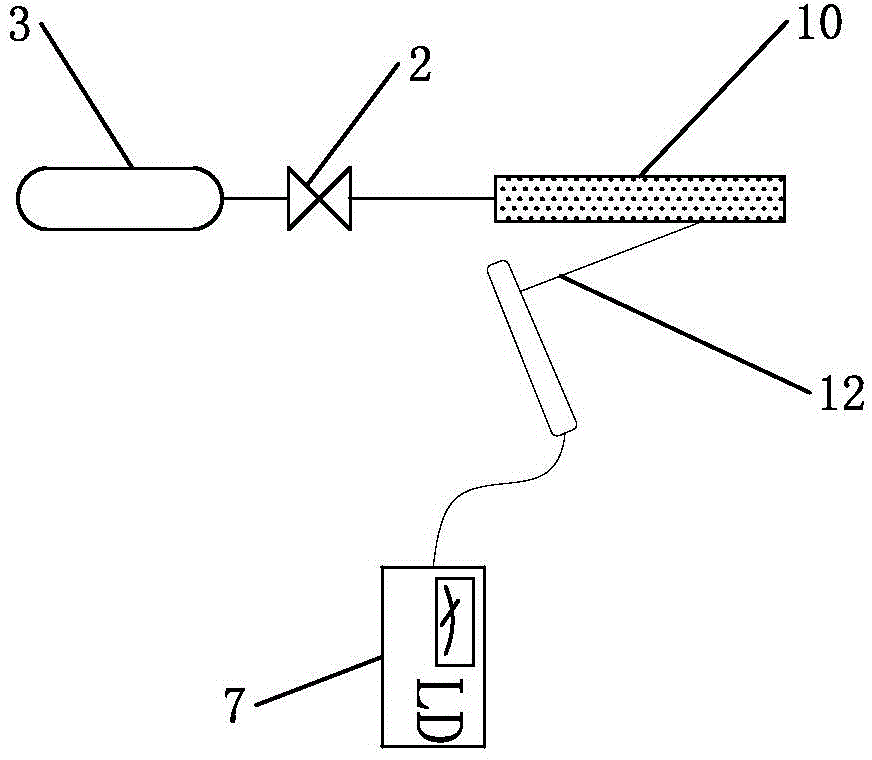

[0044] The gas concentration detection device of the present invention includes a detection box 1 providing a closed space for placing workpieces to be inspected; a tracer gas valve 2 and a tracer gas source connected to the workpiece to be inspected are arranged outside the ...

Embodiment 3

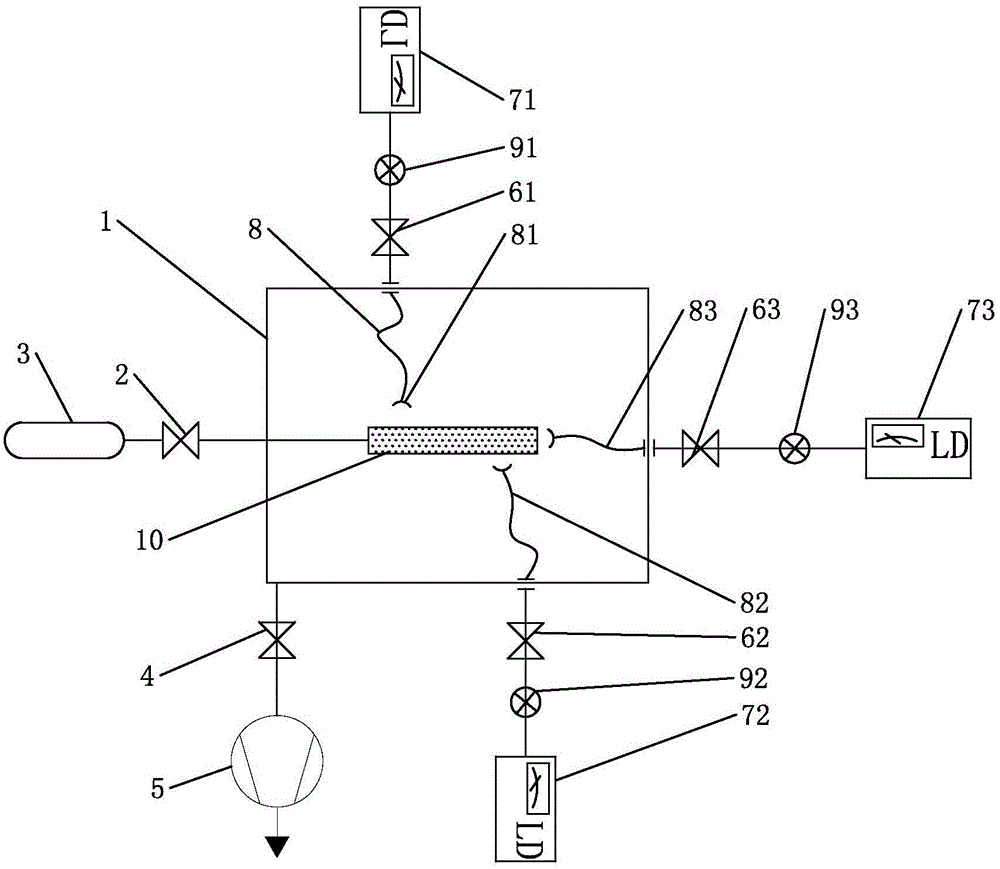

[0052] Such as Figure 5 with 6 As shown, the difference between this embodiment and Embodiment 2 is that the gas sensors are continuously arranged differently, and other structures are the same as Embodiment 2, specifically: each gas suction nozzle 8 is connected to a group of gas suction pumps 9 and The gas sensor valve 6 is connected with a gas sensor 7 uniformly afterwards. This embodiment includes three groups of gas nozzles 8, namely the first gas suction nozzle 81, the second gas suction nozzle 82 and the third gas suction nozzle 83. The first gas suction nozzle 81 is connected to the first gas sensor valve through the pipeline. 61. The first gas suction pump 91 is connected to the gas sensor 7. The second gas suction nozzle 82 is connected to the second gas sensor valve 62, the second gas suction pump 92 and the gas sensor 7 through pipelines. The gas suction nozzle 83 is connected with the third gas sensor valve 63, the third gas suction pump 93 and the gas sensor 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com