Efficient air preheating method and preheater

An air preheater, high-efficiency air technology, applied in the direction of heat exchanger type, indirect heat exchanger, heat exchange equipment, etc., can solve the problems of uncompact equipment, small heat exchange plate gap, small heat transfer area, etc. Compact equipment, high efficiency, reduced dust accumulation, and large heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

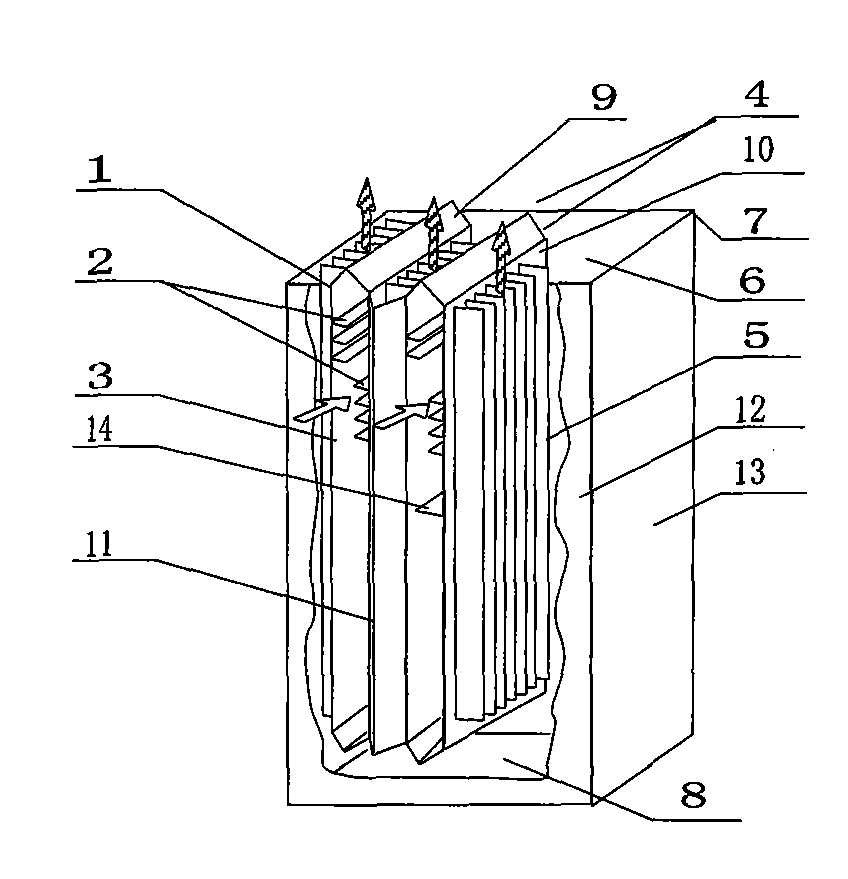

[0020] See figure 1 , is a single-box air preheater, which is applied to a flue gas air preheater with no or low sulfide. The shell 7 includes a front plate / rear plate 12 and two side plates 13. Inside the shell 7, several vertical flat Tube heat exchange unit; vertical flat tube heat exchange unit is composed of vertical flat tube 1, inner longitudinal large fins 2 and outer longitudinal large fins 5, vertical flat tube 1 consists of 2 panels 10 and 2 end plates 9 The end plate 9 is a wedge-shaped folded plate, the inner longitudinal large fins 2 and the outer longitudinal large fins 5 are arranged on both sides of the panel 10, and a connecting rib 14 is also provided between the two panels 10; two adjacent vertical flat The long side of the open end of the tube 1 is connected with a wedge-shaped bridge plate 11, and is connected and communicated with the front plate / rear plate 12; The end plate side of the vertical flat tube 1 is the inlet and outlet of the shell side, whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com