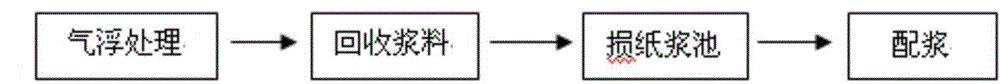

Treatment process of papermaking recovery pulp

A technology for processing and recovering pulp, which is applied in papermaking, papermaking machines, textiles and papermaking, etc. It can solve the problems of pulping and quantitative fluctuations, reduce production stability, production loss, etc., and achieve reduced loss and stable broken paper line concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

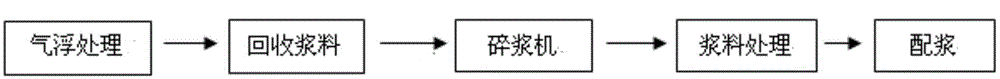

[0028] Such as figure 2 Shown, a kind of papermaking recovery slurry processing technology comprises the following steps in sequence:

[0029] (1) Air flotation process papermaking white water to obtain recycled slurry; the steps and process conditions of the air flotation method are: open the white water pump to make the white water enter the air flotation device; after the white water is about to be injected to the overflow level , turn on the driving and skimming device of the air flotation device; the air flotation device starts to operate, and adjust the inlet pressure and outlet water pressure of the steam dissolving tank so that the slurry in the white water can float normally;

[0030] The air flotation device is connected with an air compressor, the air compressor pressure is 0.8MPa, and the air flow rate is 1.0m 3 / h, the outlet pressure of the steam tank is 0.5MPa, the driving motor frequency of the air flotation device is 25Hz, and the motor frequency of the skim...

Embodiment 2

[0039] A process for treating pulp recovered from papermaking, comprising the following steps in sequence:

[0040] (1) Air flotation process papermaking white water to obtain recycled slurry; the steps and process conditions of the air flotation method are: open the white water pump to make the white water enter the air flotation device; after the white water is about to be injected to the overflow liquid level , turn on the driving and skimming device of the air flotation device; the air flotation device starts to operate, and adjust the inlet pressure and outlet water pressure of the steam dissolution tank so that the slurry in the white water can float normally;

[0041] The air flotation device is connected with an air compressor, the pressure of the air compressor is 0.6MPa, and the air flow rate is 0.8m 3 / h, the outlet pressure of the steam tank is 0.4MPa, the driving motor frequency of the air flotation device is 20Hz, and the motor frequency of the skimming device is...

Embodiment 3

[0050] A process for treating pulp recovered from papermaking, comprising the following steps in sequence:

[0051](1) Air flotation process papermaking white water to obtain recycled slurry; the steps and process conditions of the air flotation method are: open the white water pump to make the white water enter the air flotation device; after the white water is about to be injected to the overflow level , turn on the driving and skimming device of the air flotation device; the air flotation device starts to operate, and adjust the inlet pressure and outlet water pressure of the steam dissolving tank so that the slurry in the white water can float normally;

[0052] The air flotation device is connected with an air compressor, the pressure of the air compressor is 1MPa, and the air flow rate is 1.5m 3 / h, the outlet pressure of the steam tank is 0.6MPa, the driving motor frequency of the air flotation device is 30Hz, and the motor frequency of the skimmer is 15Hz.

[0053] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com