A kind of modified PBT raw material anti-caking stirring equipment and breaking up method

A stirring equipment and anti-caking technology, applied in mixer accessories, driving agitator dissolving, chemical instruments and methods, etc., can solve problems such as residues, raw material solution ratio errors, inability to effectively break blisters, etc. than exact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

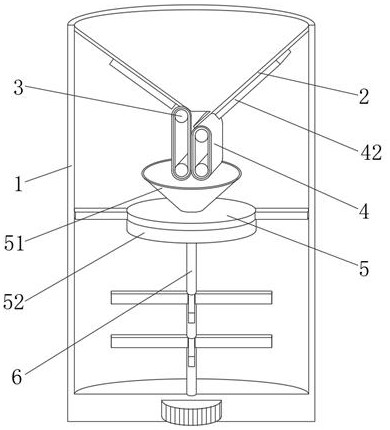

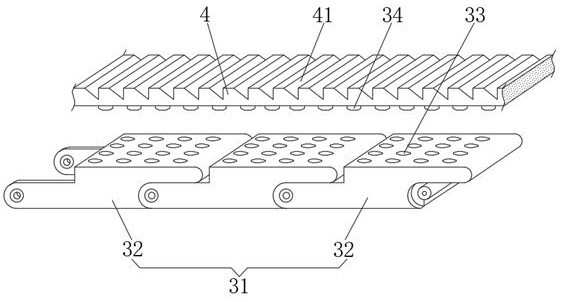

[0034] see Figure 1-5, the present embodiment provides a modified PBT raw material anti-caking stirring device, including a material barrel 1 with a built-in stirring rod 6, wherein the bottom end of the stirring rod 6 is rotatably connected with the inner wall of the bottom side of the material barrel 1, and the material barrel 1 Provide a loading space for the material. When the stirring rod 6 rotates, the stirring plate on its outer wall disturbs the mixed solution of the material and the solvent, which can increase the mixing rate between the material and the solvent. However, due to the single disturbance range of the stirring rod 6 to the solution Limited, so it is difficult to effectively disperse the dough and block materials. Among them, the opening at the top of the material barrel 1 is provided with a material inlet 2, and the material inlet 2 can be a square-shaped structure, which helps the material slide more smoothly , there will be no retention inside the mate...

Embodiment 2

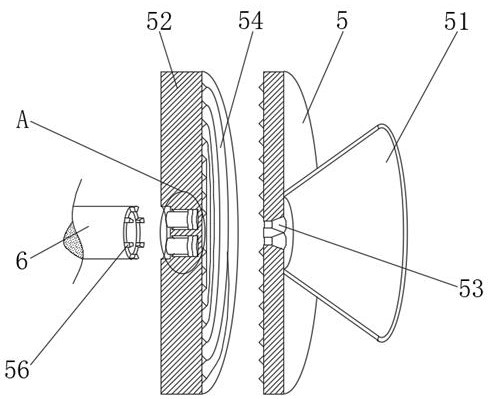

[0059] see Figure 6 , the difference from Example 1 is that: the material inlet 2 is a conical structure, the inner wall of the material barrel 1 is rotated through the annular groove 7, and the drum 71 with a conical structure is installed, and the drum 71 can be connected to the material inlet 2. Relatively rotating, the material flowing out from the side wall of the material inlet 2 is sheared between the inner wall of the drum 71 and the outer wall of the material inlet 2, which can realize crushing and breaking up of the material.

[0060] The rotating drum 71 is socketed on the outer wall of the material inlet 2, and the inside of the annular groove 7 is provided with a worm gear and a motor, which can provide a relatively stable power source for the rotating drum 71, wherein the relative distance between the rotating drum 71 and the material inlet 2 The speed of rotation should not be too fast, and the worm gear can realize the stable and continuous rotation of the rot...

Embodiment 3

[0065] see Figure 7-8 , the difference from Embodiment 2 is that: the bottom end of the material inlet 2 is a cylindrical structure, the bottom end of the material inlet 2 is rotated and installed with a material roller 8, and the material roller 8 can transmit the material inside the material inlet 2, and By controlling its rotational speed, the speed at which materials enter the grinding cylinder 81 can be effectively regulated.

[0066] The outer wall at the bottom of the material inlet 2 is fixed with a cylindrical grinding cylinder 81, and the inside of the grinding cylinder 81 is rotated with a grinding roller 82, and the outer wall of the grinding roller 82 is provided with a plurality of grinding blocks 83. The roller 82 drives the relative rotation between the grinding block 83 and the grinding plate 84, which can grind the material, and can decompose and disperse the particles and blocks remaining in the boring.

[0067] The inner wall of the grinding cylinder 81 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com