Electrolytic foil, electrical component containing electrolyte foil and battery

A technology of electrolytic copper foil and pores, applied in the direction of electrolysis, electroforming, etc., can solve the problems of weak mechanical strength, copper foil thickness limitation, etc., and achieve the effects of high gloss, process reduction, and high elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] In order to produce electrolytic copper foil by electrolysis, a 3L capacity electrolytic cell system that can circulate at 20L / min was used, and the temperature of the copper electrolyte was kept constant at 45°C. The anode uses a thickness of 5mm and a size of 10×10cm 2 The DSE (Dimentionally Stable Electrode) plate, the cathode uses a titanium plate with the same size and thickness as the anode.

[0089] To make Cu 2+ Smooth movement of ions at 35A / dm 2 Gold plating was performed at a current density of 18 μm to produce an electrolytic copper foil with a thickness of 18 μm.

[0090] The basic components of copper electrolyte are as follows:

[0091] CuSO 4 ·5H 2 O: 250~400g / L

[0092] h 2 SO 4 : 80~150g / L

[0093] Chloride ions and additives were added to the above-mentioned copper electrolytic solution, and the components of the added additives and chloride ions are shown in Table 1 below. In Table 1 below, ppm is the same concentration as mg / L.

[0094] A...

Embodiment 2 to 4 and comparative example 1 to 4

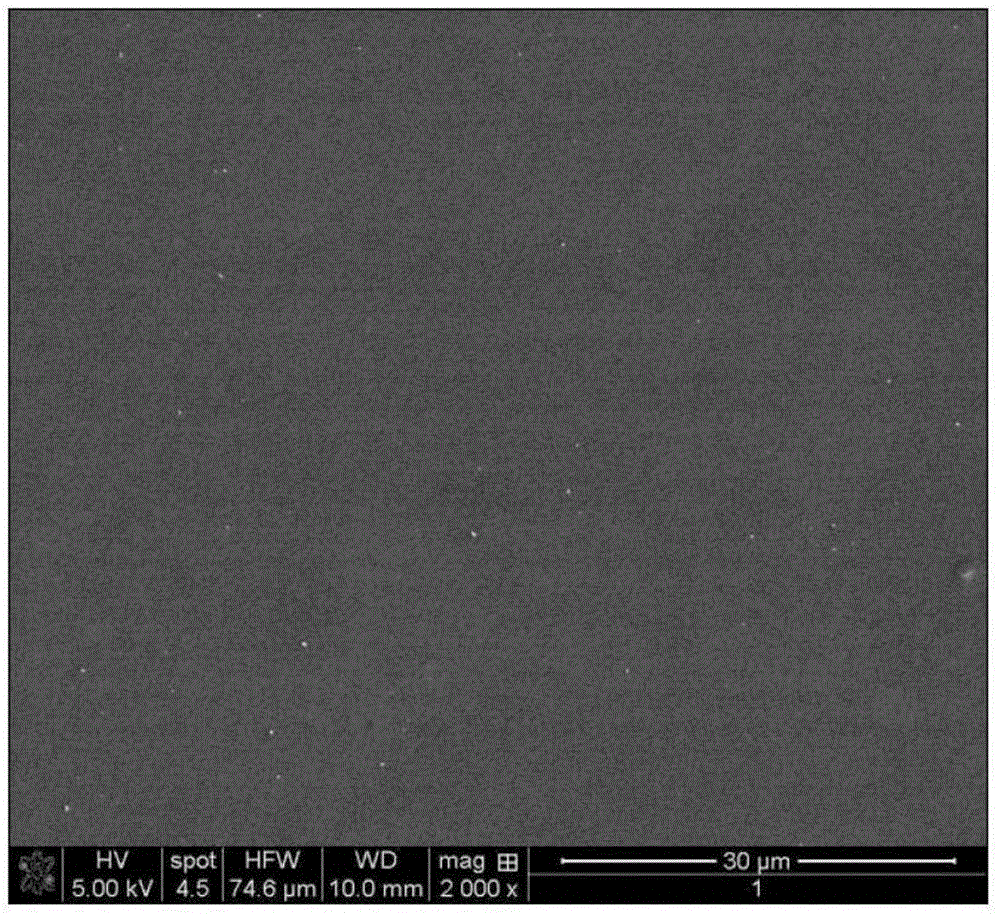

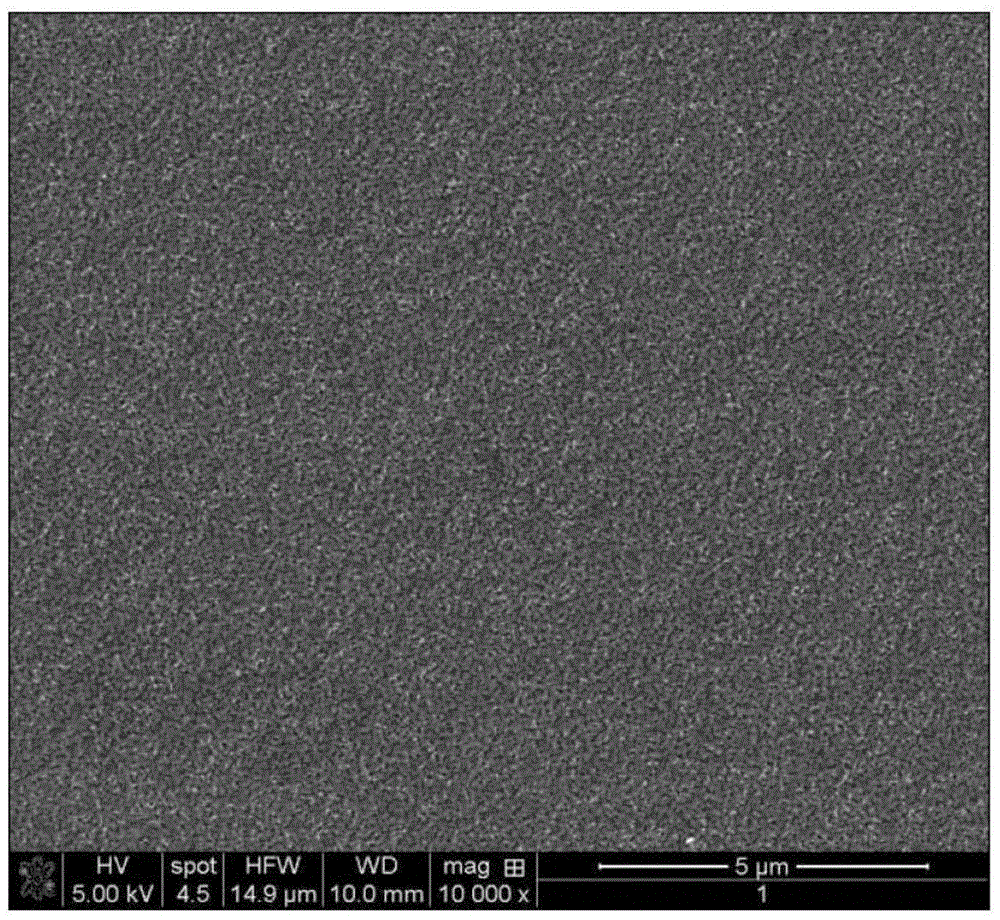

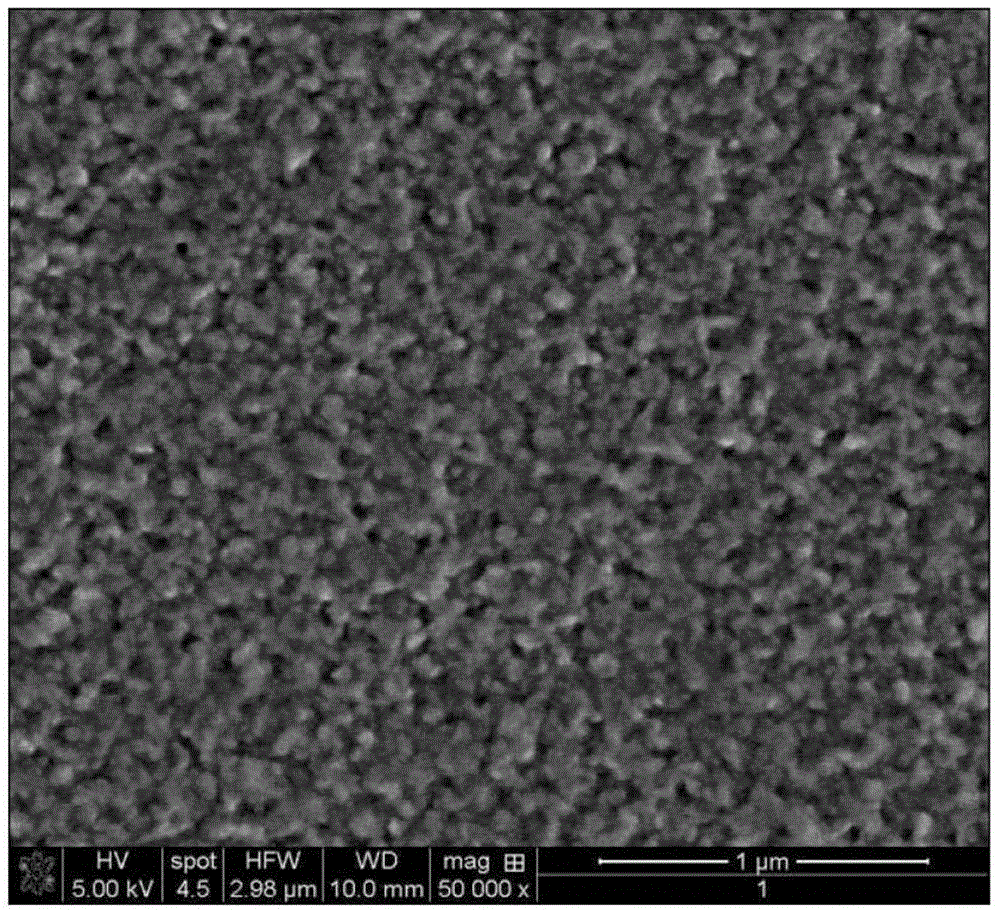

[0096] Electrolytic copper foil was produced in the same manner as in Example 1 except that the composition of the copper electrolytic solution was changed as shown in Table 1 below. Scanning electron micrographs of the deposition surface of the electrodeposited copper foil produced in Examples 2 to 4 and Comparative Examples 1 to 4 are shown in Figures 8 to 14 .

[0097] 【Table 1】

[0098]

[0099] In the above Table 1, the abbreviations represent the following compounds.

[0100] DET: Diethylthiourea

[0101] SPS: bis-(3-sulfopropyl)-disulfide disodium salt

[0102] MPS: 3-Mercapto-1-propanesulfonic acid

[0103] PEG: polyethylene glycol (kanto chemical Cas No. 25322-68-3)

[0104] ZPS: Sodium 3-(benzothiazolyl-2-mercapto)-propyl-sulfonate

[0105] JGB: Kenna Green B

[0106] 2M-SS: 2-Mercapto-5-benzimidazolesulfonic acid

[0107] DDAC: Diallyldimethylammonium chloride

[0108] PGL: Polyglycerol (KCI, PGL 104KC)

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com