Magnesium alloy and preparing method thereof

A technology of magnesium alloy and master alloy, which is applied in the field of metal alloys, can solve the problems of low cost and inability of magnesium alloy to have thermal conductivity, etc., and achieve the effect of good die-casting performance, less types and dosage, and excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

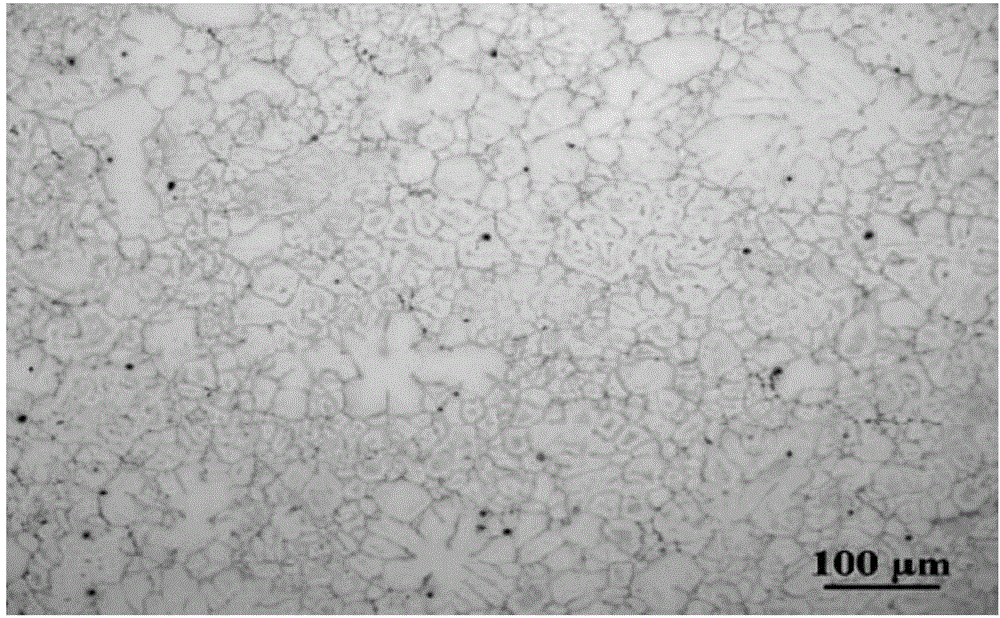

Image

Examples

preparation example Construction

[0037] The present invention also provides a method for preparing a magnesium alloy. In a preferred embodiment, the method for preparing a magnesium alloy includes the following steps:

[0038] S1. Provide raw materials: magnesium ingots, zinc ingots, magnesium-samarium master alloys and magnesium-zirconium master alloys, and weigh the raw materials according to the weight percentages of the components in the above-mentioned magnesium alloys;

[0039] S2, preheating the raw materials;

[0040] S3, place the magnesium ingot in N 2 and SF 6 Heating to complete melting under the protection of mixed gas, and controlling the magnesium melt to maintain at 650°C to 780°C; adding magnesium-samarium master alloy to the magnesium melt at 680°C to 750°C until the magnesium-samarium master alloy is completely melted; then Add zinc ingots, after the zinc ingots are completely melted, add magnesium-zirconium master alloy into the melt at 750°C~780°C until the magnesium-zirconium master al...

Embodiment 1

[0046] The Mg-3Sm-0.5Zr (wt.%) magnesium alloy of 50Kg and its die casting preparation method:

[0047]1. Ingredients: Weigh 43.2Kg of magnesium ingot, 6Kg of Mg-25Sm master alloy and 0.84Kg of Mg-30Zr master alloy, wherein the purity of magnesium ingot is 99.94wt.%, Mg-25Sm master alloy and Mg-30Zr The purity of the master alloy is 99.9 wt.%.

[0048] 2. Preheating: Preheating each component with the above-mentioned ingredients.

[0049] 3. Melting: Put all the magnesium ingots into the well-type resistance crucible furnace as tightly as possible; seal the crucible and put it into SF 6 and N 2 After the mixed gas, the temperature is raised to completely melt the magnesium ingot under the protective gas, and the temperature of the magnesium is kept at 680-780°C; when the temperature of the magnesium melt rises to 680-750°C, add the preheated Mg-25Sm master alloy into the magnesium melt Keep the temperature in the liquid for an appropriate time until the Mg-Sm master alloy i...

Embodiment 2

[0060] The Mg-3.5Sm-0.6Zr (wt.%) magnesium alloy of 50Kg and its die-casting preparation method:

[0061] Ingredients: Weigh 42Kg of magnesium ingot, 7Kg of Mg-25Sm master alloy and 1Kg of Mg-30Zr master alloy, wherein the purity of magnesium ingot is 99.94wt.%, the purity of Mg-25Sm master alloy and Mg-30Zr master alloy It is 99.9wt.%. Other steps are basically the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com