Method of producing aromatic hydrocarbon through catalytic conversion of organic oxides

A technology of organic oxides and catalytic conversion, which is applied in the direction of hydrocarbon production from oxygen-containing organic compounds, organic chemistry, and chemical recovery. Good aromatization effect, good BTX selectivity, the effect of reducing pipeline and equipment wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

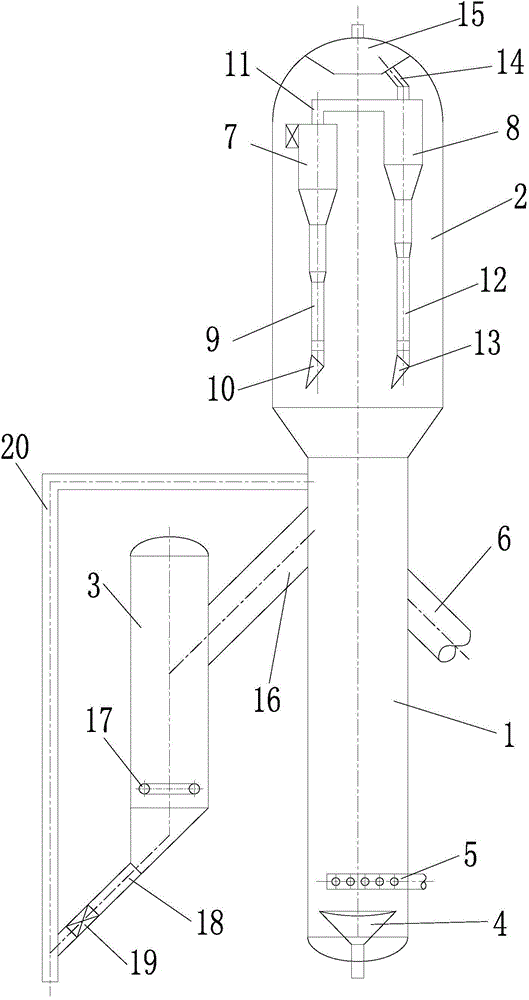

[0036] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0037] The invention provides a method for preparing aromatics by catalytic conversion of organic oxides, the method comprising:

[0038] The organic oxide is sent into the fluidized bed reactor from the bottom of the dense phase bed reaction section at the lower part of the fluidized bed reactor, where the dense phase bed reaction section is in contact with the aromatization catalyst and aromatization reaction occurs;

[0039] The oil gas with a small amount of catalyst after the reaction in the dense-phase bed reaction section is sent to the dilute-phase section of the reactor on the upper part of the fluidized bed reactor, and the reaction product and the unborn catalyst are separated in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com