Untwisting pipe component and joint device having same

A splicing device and untwisting tube technology, which are applied in the directions of transportation and packaging, thin material handling, and filamentary material transportation, can solve the problems of difficulty in maintaining shape accuracy and low yield of untwisted tubes, and achieve a high yield rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

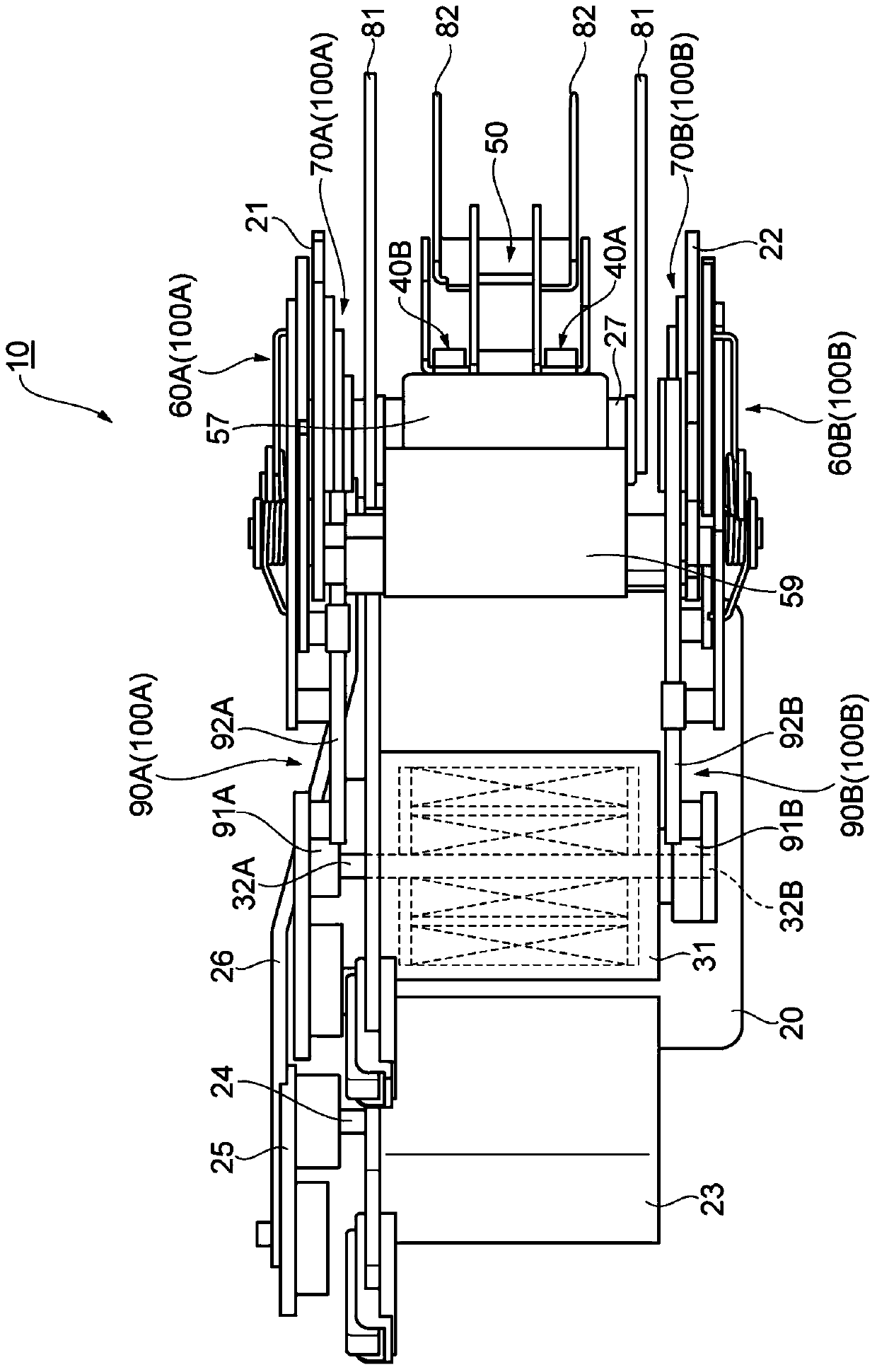

[0086] In the first untwisting pipe member 40A and the second untwisting pipe member 40B of the above-mentioned embodiment, an example formed of two cylindrical members, the first untwisting pipe 41 and the second untwisting pipe 43, has been described. However, it may be formed by three or more cylindrical members. In this way, by adopting a structure in which a plurality of cylindrical members are connected in the axial direction, it is possible to easily form untwisting tube members of various lengths, and it is possible to commonize the members.

[0087]

[0088] In the first untwisting pipe member 40A and the second untwisting pipe member 40B of the above-mentioned embodiment, the first untwisting pipe 41 is made of ceramics and the second untwisting pipe 43 is made of polyacetal resin. description, but the present invention is not limited thereto. For example, both the first untwisting tube 41 and the second untwisting tube 43 may be made of ceramics. In this case, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com