Underground coal and gangue separation system and coal and gangue separation method

A coal gangue separation and coal gangue separation technology, which is applied in the underground coal gangue sorting system and the coal gangue sorting field, can solve the problems of ground environmental pollution, declining profit per ton of coal, and land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below through specific embodiments and in conjunction with the accompanying drawings.

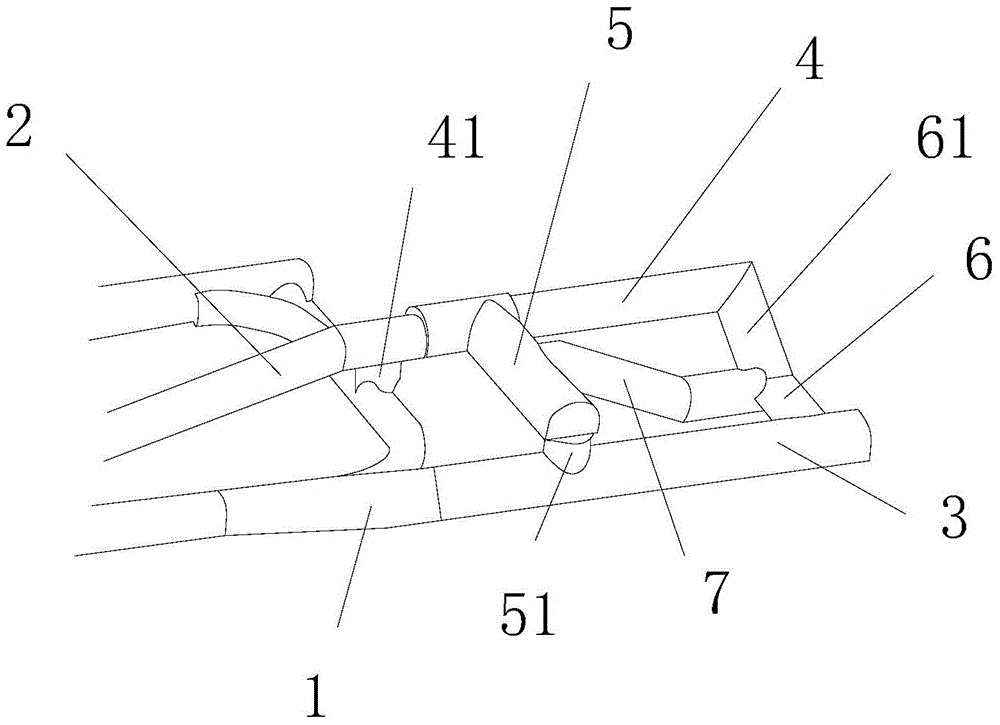

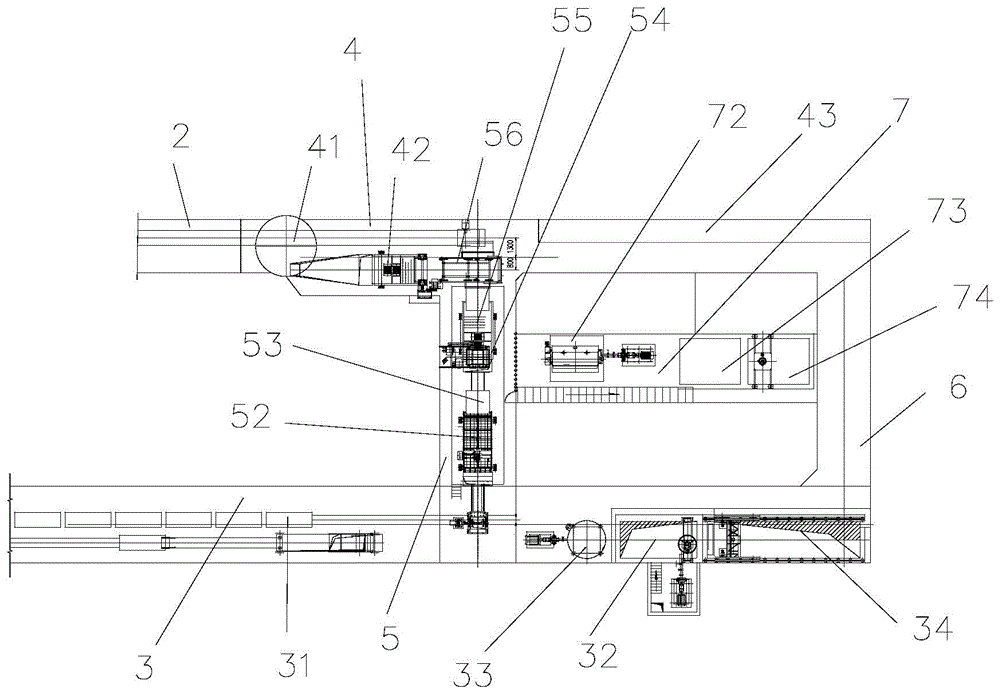

[0032] Such as figure 1 and figure 2 The underground coal gangue sorting system shown includes:

[0033] Material transportation roadway 1 for the transportation of materials above and below the mine;

[0034] Bottom coal gangue sorting channel 2 for transporting raw coal;

[0035] The first roadway 3 forms a well bottom car park 31 at the junction with the material transportation roadway 1, and the inside of the first roadway 3 is sequentially provided with a coal slime collection bucket 32 and a circulating water pool in a direction away from the bottom well car park 31 33 and scraping suction pool 34;

[0036] The second roadway 4 is connected to the coal gangue sorting channel 2 at the bottom of the shaft and forms a gangue bin 41 at the junction, and a gangue removal screen 42 connected to the gangue bin 41 and an electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com