Solid electrolyte material with high ion conductivity and strong mechanical properties and preparation method thereof

A solid electrolyte, ionic conductivity technology, applied in electrolytes, circuits, electrical components, etc., can solve problems such as explosion, flammability, liquid leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

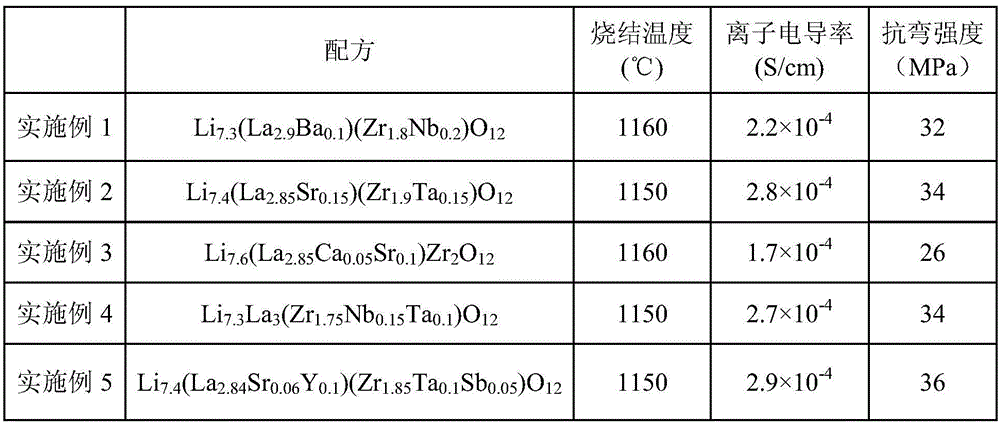

Embodiment 1-5

[0058] The chemical formula of embodiment 1-5 is Li 6+x (La z A 3-z )(Zr n G 2-n )O 12 .

[0059] Ingredients: A is at least one selected from Ca, Sr, Y, and Ba, G is at least one selected from Ti, Nb, Ta, Sb, and V, and satisfies 0≤x≤2, 2≤z≤ 3. 1≤n≤2, the solid electrolyte material of the present invention is prepared through the following steps:

[0060] (1) Using analytically pure chemical reagent Li 2 CO 3 , La 2 o 3 , CaCO 3 、BaCO 3 , ZrO 2 , SrCO 3 , Y 2 o 3 、TiO 2 , Nb 2 o 5 、 Ta 2 o 5 , Sb 2 o 3 , V 2 o 5 as raw material, according to Li 6+x (La z A 3-z )(Zr n G 2-n )O 12 The general chemical formula configures the molar ratio of raw materials, where 0≤x≤2, 2≤z≤3, 1≤n≤2. Put the prepared raw materials into a 50KG horizontal ceramic ball mill for ball milling for 16 hours;

[0061] (2) After drying the ball-milled slurry, press it into a large sheet with a diameter of 40 mm under a pressure of 30 MPa, and pre-burn it at 800 ° C for 4 hour...

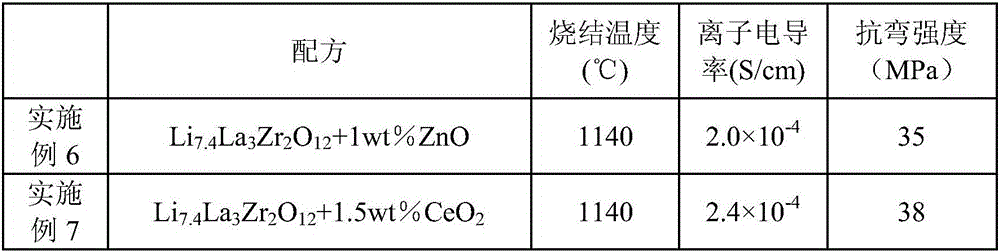

Embodiment 6-10

[0070] According to the general formula of chemical composition Li 6+x La 3 (Zr n G 2-n )O 12 +αwt%D ingredients, wherein G is at least one selected from Ti, Nb, Ta, Sb, V, and D is selected from SiO 2 、 Bi 2 o 3 , B 2 o 3 , CeO 2 , ZnO, CuO, MnO 2 、Co 2 o 3 , SnO 2 At least one of them, and satisfy 0≤x≤2, 1≤n≤2, 0<α≤3, and prepare the solid electrolyte material of Examples 6-10 through the following steps:

[0071] (1) Using analytically pure chemical reagent Li 2 CO 3 , La 2 o 3 , ZrO 2 、TiO 2 , Nb 2 o 5 、 Ta 2 o 5 , Sb 2 o 3 , V 2 o 5 as raw material, according to Li 6+x La 3 (Zr n G 2-n )O 12 The molar ratio of the general chemical formula, where 0≤x≤2, 1≤n≤2. Put the prepared raw materials into a 50KG horizontal ceramic ball mill for ball milling for 16 hours;

[0072] (2) After drying the ball-milled slurry, press it into a large sheet with a diameter of 40 mm under a pressure of 30 MPa, and pre-burn it at 950 ° C for 4 hours at a heating...

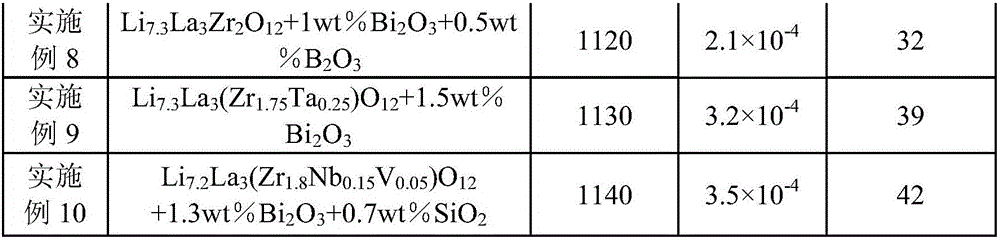

Embodiment 11-14

[0082] According to the general formula of chemical composition Li 6+x (La z A 3-z )Zr 2 o 12 +αwt% D ingredients, wherein A is at least one selected from Ca, Sr, Y, Ba, and D is selected from SiO 2 、 Bi 2 o 3 , B 2 o 3 , CeO 2 , ZnO, CuO, MnO 2 、Co 2 o 3 , SnO 2 At least one of them, and satisfying 0≤x≤2, 2≤z<3, 0<α≤3, using the same preparation method as in Examples 6-10 to prepare solid electrolyte materials.

[0083] See Table 3 for the chemical formulas and test results of the solid electrolyte materials in Examples 11-14.

[0084] The chemical formula and test result thereof of the solid electrolyte material of table 3 embodiment 11-14

[0085]

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com