Wave power generation device using spiral structure and working method thereof

A technology of power generation device and spiral structure, which is applied in the fields of ocean energy power generation, engine function, engine components, etc., can solve problems such as damage to device parts, and achieve the effects of stable operation, good corrosion resistance and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

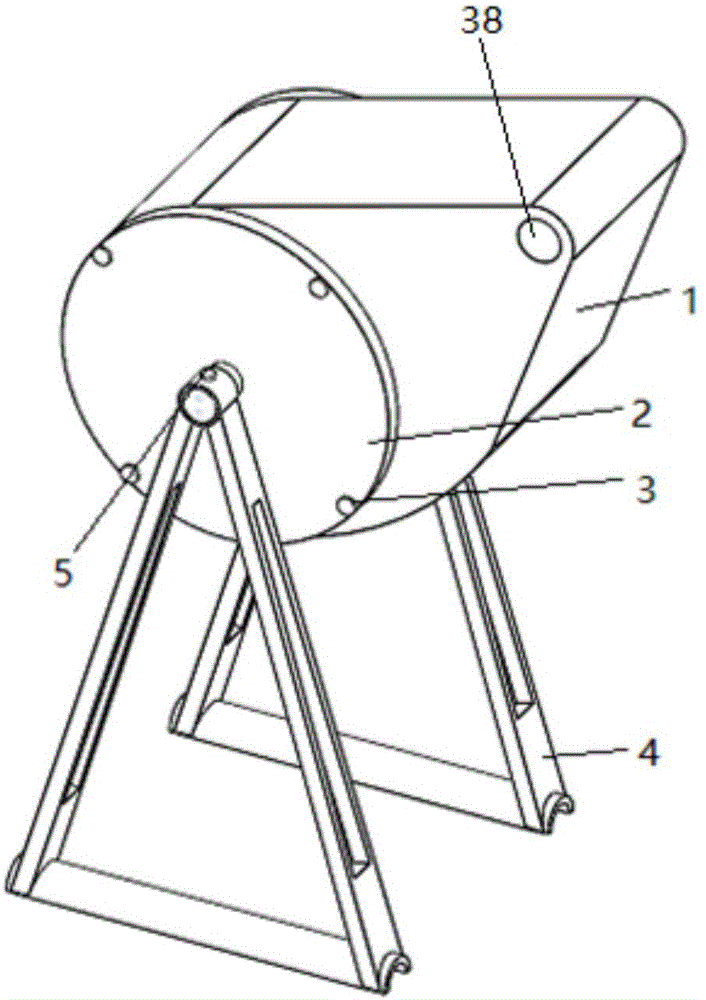

[0071] A wave energy generating device utilizing a spiral structure, comprising a wave energy collector, a bracket connected to the wave energy collector, a wave energy conversion main mechanism arranged inside the wave energy collector, an energy transmission device and an energy output device;

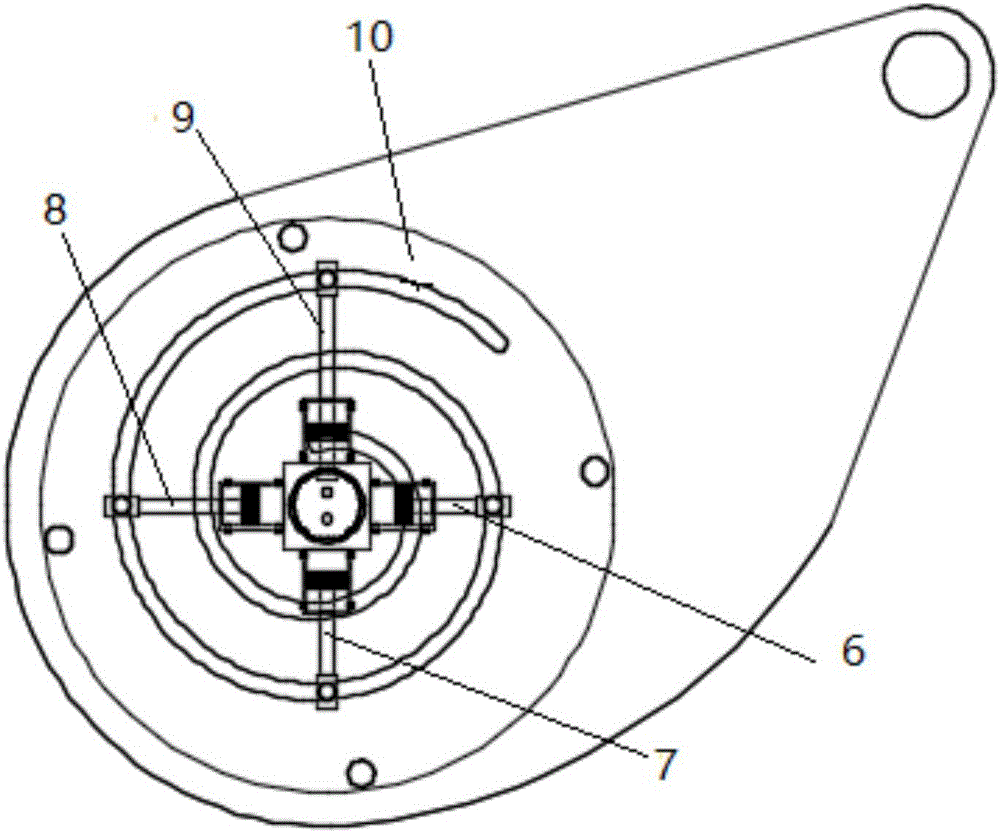

[0072] The wave energy collector includes a cavity and a cam body arranged outside the cavity, and the cavity is a cylindrical cavity;

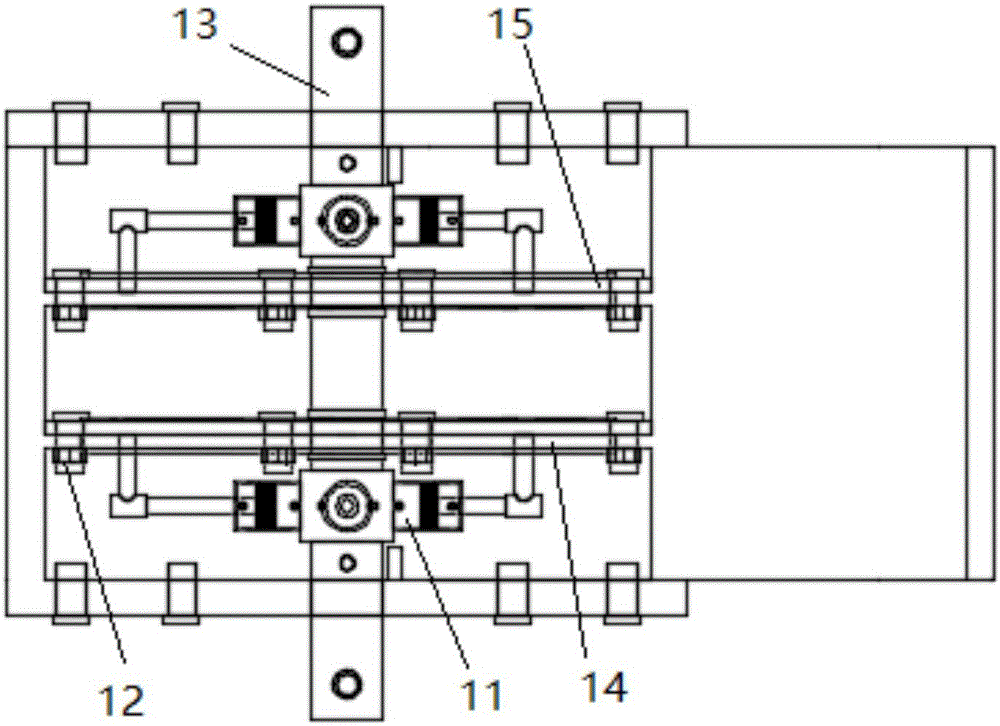

[0073] The main mechanism of wave energy conversion is located in the cylindrical cavity. The main mechanism of wave energy conversion is provided with a fixed shaft. The main mechanism of wave energy conversion includes a screw turntable, a piston rod group, and a hydraulic cylinder. The hydraulic cylinder is connected with the fixed shaft. The bracket bolt group is connected with the bracket, the screw turntable is connected with the piston rod group, the piston rod group is connected with the hydraulic cylinder, and the screw turntable is connecte...

Embodiment 2

[0078] A wave energy power generation device using a spiral structure, the structure is as described in Embodiment 1, the difference is that the cam body of the wave energy harvester is provided with ups and downs and floating holes. Floating bodies such as foam plastics can be added to the heave and float holes, so that the heave and float holes will heave up and down with the heave motion of the wave, which is specifically manifested as the swing of the wave energy harvester around the fixed axis, so that the wave energy harvester can control the wave's rise and fall. The potential energy of the sinking motion is transformed into the mechanical energy of its own swing. In addition, the kinetic energy of the wave impact movement captured by the wave energy harvester makes the wave energy harvester have a higher wave energy capture capability.

Embodiment 3

[0080] A wave energy generating device using a spiral structure, the structure is as described in Embodiment 1, the difference is that the wave energy generating device utilizing a spiral structure also includes a support baffle, and the support baffle is arranged outside the main wave energy conversion mechanism At both ends, the wave energy conversion main mechanism is bolted to the wave energy harvester through the support baffle, and the support baffle is connected to the fixed shaft through the bearing. The support baffle is located at the outermost side of the main wave energy conversion mechanism, and is fixedly connected to the wave energy harvester through the support baffle bolt group to play the role of support and sealing, and at the same time swings with the swing of the wave energy harvester.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com