Control method and system for steelmaking process of electric arc furnace through preheating type oxygen gun

A process control and electric arc furnace technology, applied in the field of electric arc furnace steelmaking, can solve the problems that the oxygen jet oxidation ability and impact stirring ability cannot be independently controlled, and the oxygen supply parameters are single, so as to achieve optimization effects and economic benefits, and has broad application prospects. The effect of shortening the decarburization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

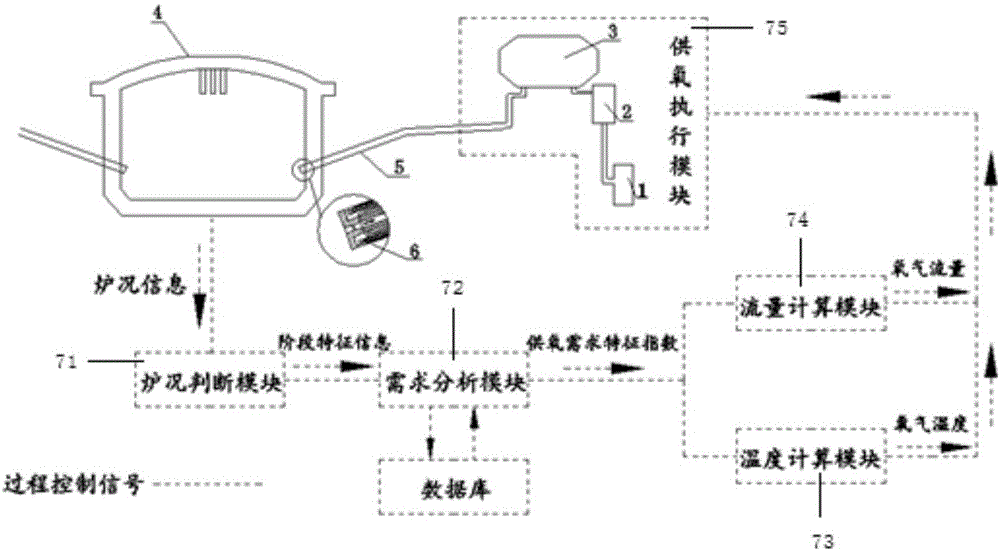

[0055] Such as figure 1 As shown, this embodiment is an application on a 100-ton ultra-high power EBT electric arc furnace. Oxygen starts from the oxygen source 1, passes through the oxygen flow control valve group 2, and then passes through the temperature control system 3, and enters through the electric arc furnace body 4 In the electric arc furnace, the electric arc furnace has a total of 4 furnace wall preheating oxygen lances and 1 furnace door preheating oxygen lance. The oxygen heating method of the temperature control system 3 adopts the method of flue gas heat exchange + electric heating. The wall preheating oxygen lance nozzle 6 has a design Mach number of 2.0 and a design flow rate of 2000Nm 3 / h, oxygen stagnation pressure 0.814MPa.

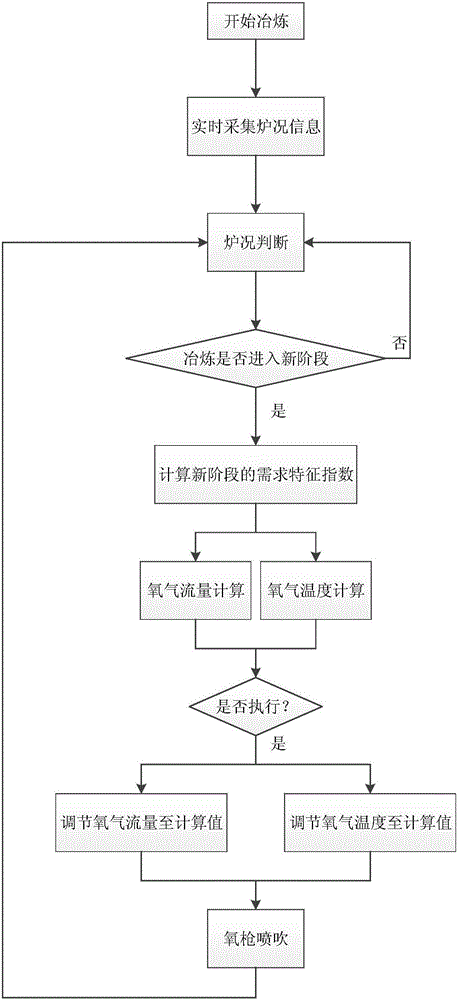

[0056] Oxygen flow and temperature are controlled by computer in different time periods. The electric arc furnace control system includes an oxygen control system. The oxygen control system consists of a furnace condition judgment m...

Embodiment 2

[0064] This embodiment is an application on a 150-ton ultra-high power EBT electric arc furnace, oxygen starts from oxygen source 1,

[0065] Through the oxygen flow control valve group 2, and then through the temperature control system 3, it enters the electric arc furnace through the electric arc furnace body 4. The electric arc furnace has a total of 5 furnace wall preheating oxygen lances 5 and a furnace door preheating oxygen lance 1 The oxygen heating method adopts the electric heating method, the design Mach number of the oxygen lance nozzle is 2.0, and the design flow rate is 3000Nm 3 / h, oxygen stagnation pressure 0.814MPa.

[0066] Oxygen flow and temperature are controlled by computer in different time periods. The electric arc furnace control system includes an oxygen control system. The oxygen control system consists of a furnace condition judgment module 71, a demand analysis module 72, a flow calculation module 74, a temperature calculation module 73 and an oxyg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com