Silicon quantum dot aqueous phase preparation method

A technology for the preparation of silicon quantum dots and water phase, which is applied in chemical instruments and methods, nanotechnology, nano-optics, etc., can solve problems such as low quantum yield, and achieve the effects of simple synthesis operation, easy availability of raw materials, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The method for synthesizing water-soluble silicon quantum dots by hydrothermal method with 3-aminopropyltrimethoxysilane as silicon source, its specific steps are as follows:

[0036] (1) Dissolve citric acid and sodium borohydride in deionized water under the protection of nitrogen, and then add 3-aminopropyltrimethoxysilane as a silicon source to control the silicon source: the molar ratio of citric acid: sodium borohydride = 1:0.2:0.2, wherein the concentration of 3-aminopropyltrimethoxysilane in water is 44mmol / L, the concentration of citric acid in water is 8.8mmol / L, and the concentration of sodium borohydride in water is 8.8mmol / L .

[0037] (2) Transfer the mixed solution into a high-pressure reactor and heat it to 140° C., and react for 3.5 hours to obtain a silicon quantum dot solution.

[0038] (3) Mix the prepared silicon quantum dot solution with methanol at a volume ratio of 1:3, centrifuge at 8000r / min for 10min, remove the supernatant, and freeze-dry th...

Embodiment 2

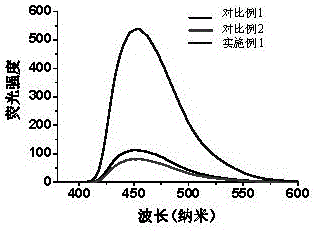

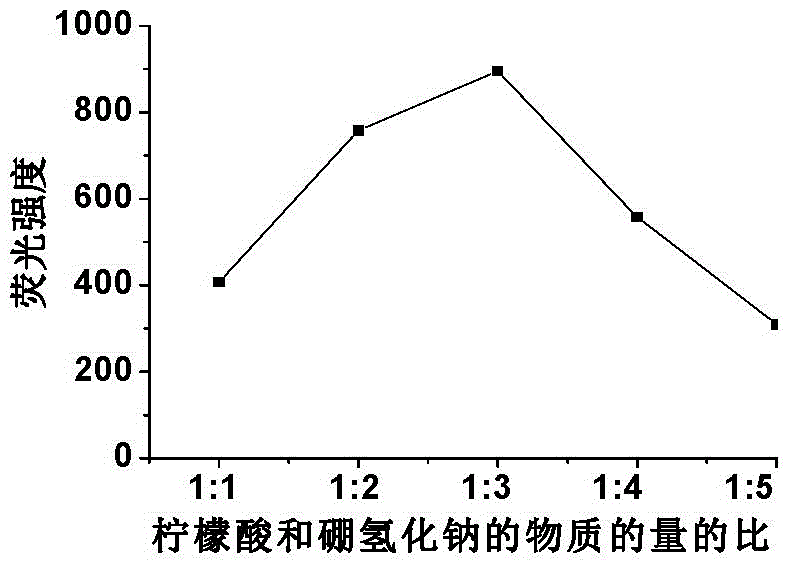

[0052] Using 3-aminopropyltrimethoxysilane as the method for silicon source hydrothermal synthesis of water-soluble silicon quantum dots, its preparation method is the same as in Example 1, the concentration of 3-aminopropyltrimethoxysilane in water is 44mmol / L , the difference lies in the different concentrations of the reducing agent citric acid and sodium borohydride. The molar ratio of 3-aminopropyltrimethoxysilane:citric acid:sodium borohydride is 1:0.2:0.2~1. After measurement, the fluorescence intensity of silicon quantum dots prepared under different ratios is shown in image 3 .

[0053] For each ratio, the quantum yield is shown in the table below:

[0054] Molar ratio of 3-aminopropyltrimethoxysilane:citric acid:sodium borohydride

1:0.2:0.2

1:0.2:0.4

1:0.2:0.6

1:0.2:0.8

1:0.2:1

32%

57%

67%

49%

45%

[0055] It has been determined that the quantum dots prepared in this embodiment have good pH stabilit...

Embodiment 3

[0058] The method for synthesizing water-soluble silicon quantum dots by hydrothermal method with 3-aminopropyltriethoxysilane as silicon source, its specific steps are as follows:

[0059] (1) Dissolve 3-aminopropyltriethoxysilane in deionized water under the protection of argon, the concentration of 3-aminopropyltrimethoxysilane in water is 44mmol / L, then add sodium borohydride and Sodium sulfite, control silicon source: sodium borohydride: sodium sulfite molar ratio=1:1:0.5.

[0060] (2) Transfer the stirred and evenly mixed solution into an autoclave and heat it to 170° C., and react for 2 hours to obtain a silicon quantum dot solution.

[0061] (3) Mix the obtained silicon quantum dot solution with ethanol evenly at the ratio of quantum dots:ethanol=1:2. Centrifuge at 8000r / min for 15min, remove the supernatant, and vacuum-dry the resulting precipitate to obtain solid silicon quantum dots.

[0062] The quantum yield of this embodiment is 50%.

[0063] It has been deter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com