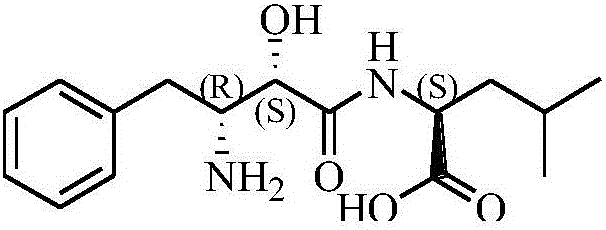

Preparation method of high-purity Ubenimex

A technology of ubimethoxine and high purity, applied in the field of preparation of high-purity ubimethoxine, can solve the problems of expensive condensing agent, unfavorable industrial production, time-consuming 24 hours, etc. Reagent cost, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: the preparation method of Ubenimex

[0035] Put 40.0 g of crude ubenimex into 1600 mL of a mixed solution of ethanol and water (volume ratio of water: ethanol = 1:1), and stir evenly. Then heat to an internal temperature of 80°C, keep stirring until the solids are completely dissolved. Stop heating, cool down to 6°C at a constant speed, keep stirring for 30 minutes, and then filter with suction. The filter cake is vacuum-dried at 60°C to obtain a dry weight of 33.0g, a yield of 82.5%, a purity of 99.82%, and a maximum purity of 0.12%.

Embodiment 2

[0036] Embodiment 2: the preparation method of Ubenimex

[0037] Put 10.0g of crude ubenimex into 600mL ethanol aqueous solution (water:ethanol volume ratio=1:1), and stir evenly. Then heat to an internal temperature of 78°C and keep stirring until the solids are completely dissolved. Stop heating, cool down to 8°C at a constant speed, keep stirring for 30 minutes, then suction filter, and vacuum-dry the filter cake at 60°C to obtain a dry weight of 7.75g, a yield of 77.5%, a purity of 99.82%, and a maximum purity of 0.11%.

Embodiment 3

[0038] Embodiment 3: the preparation method of Ubenimex

[0039] Put 10.0g of crude ubenimex into 1000mL ethanol aqueous solution (water:ethanol volume ratio=1:1), and stir evenly. Then heat to an internal temperature of 75°C and keep stirring until the solids are completely dissolved. Stop heating, cool down to 8°C at a constant speed, keep stirring for 30 minutes, and then filter with suction. The filter cake is vacuum-dried at 60°C to obtain a dry weight of 5.42g, a yield of 54.2%, a purity of 99.83%, and a maximum purity of 0.10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com