Thermal phosphoric acid waste heat utilization device with steam superheater

A thermal phosphoric acid and superheater technology, applied in the direction of steam superheating, phosphoric acid, steam generation, etc., to achieve good economic benefits, high energy utilization efficiency, and improved waste heat recovery efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

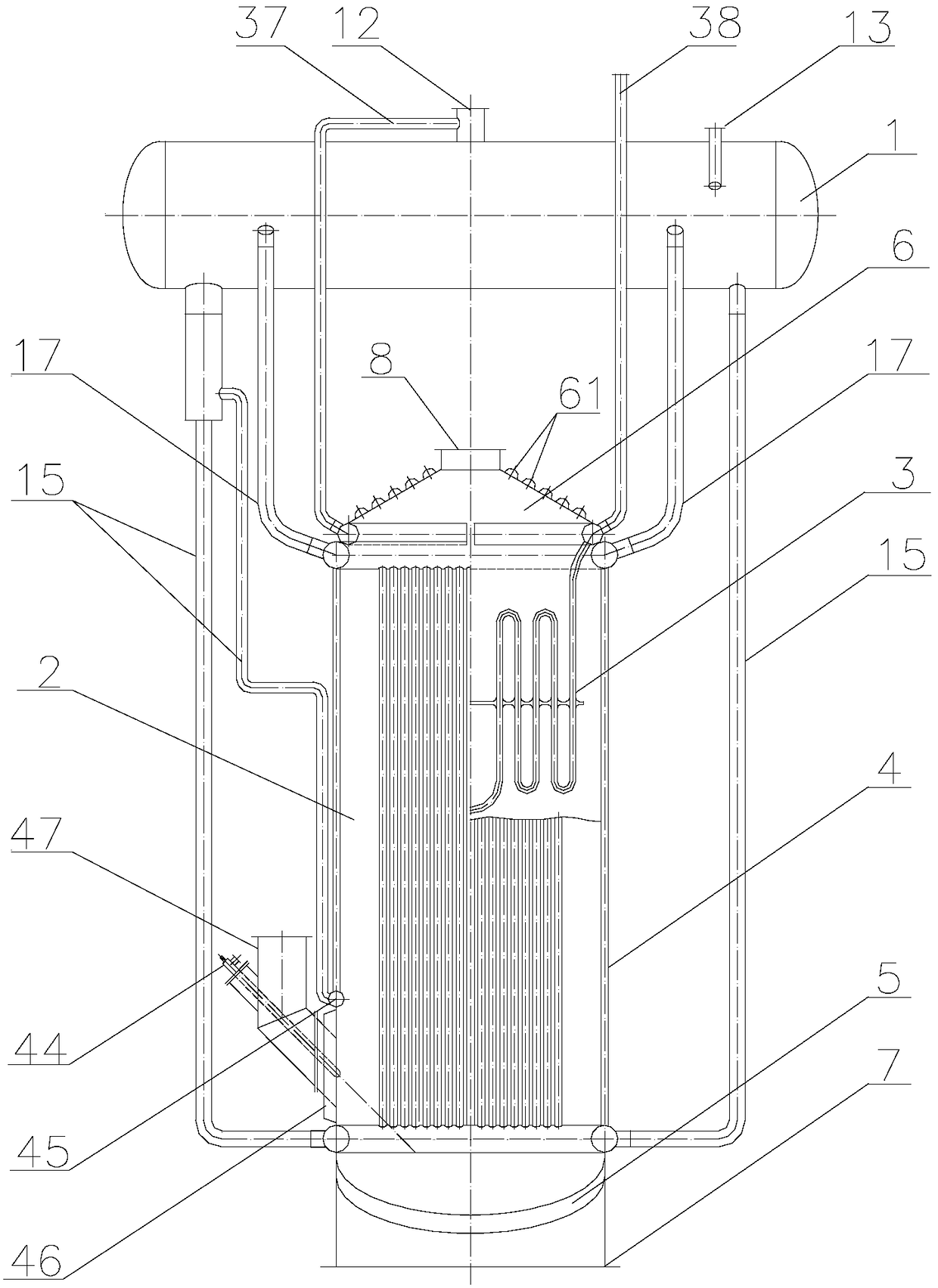

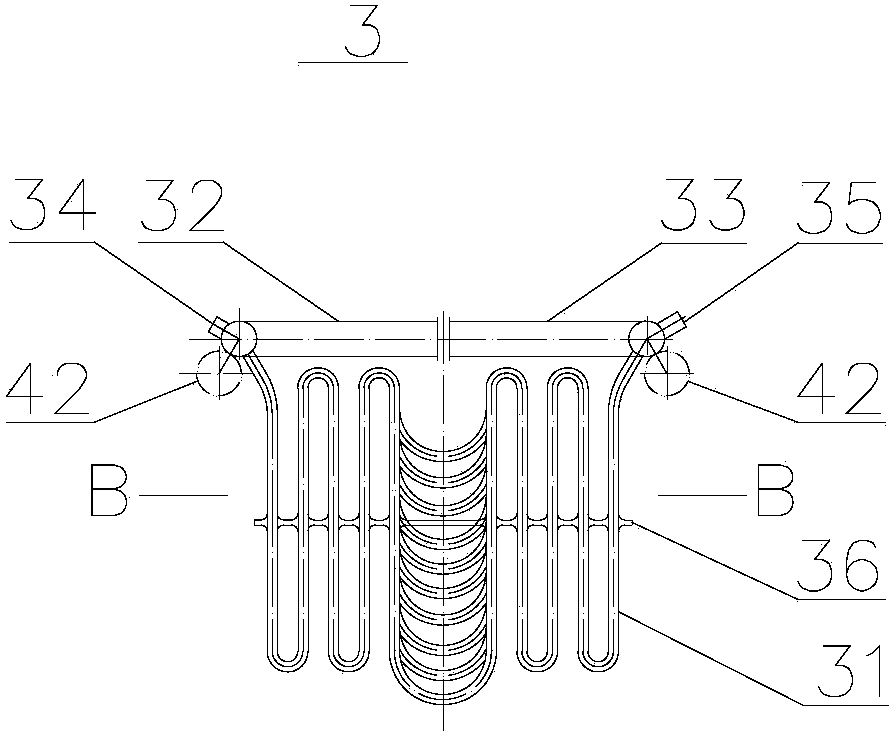

[0037] Such as Figure 1-9 As shown, a thermal phosphoric acid waste heat utilization device with a steam superheater of the present invention includes a steam drum 1, a phosphorus combustion tower 2 and a steam superheater 3 arranged inside the phosphorus combustion tower 2, and the steam drum 1 is located in the phosphorus combustion tower The upper part of 2.

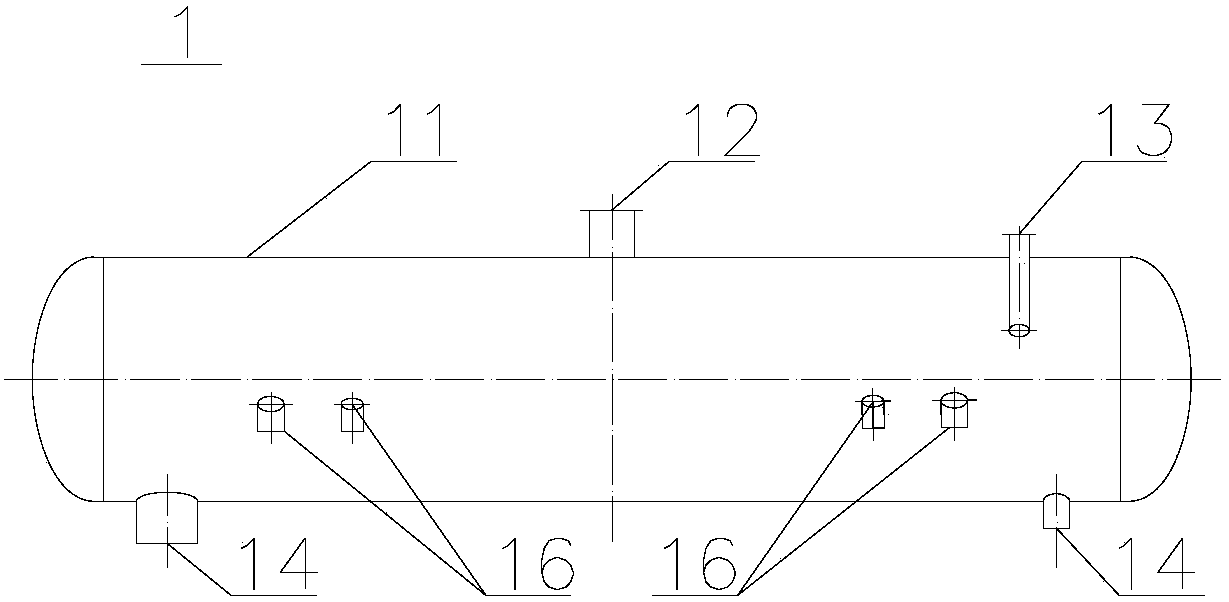

[0038] Such as figure 2 As shown, the steam drum 1 includes a housing 11, the top of the housing 11 is provided with a steam outlet pipe 12, the steam outlet pipe 12 is fixedly connected to the steam introduction pipe 37, and the housing 11 is provided with a supplementary water connecting pipe for replenishing wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com