High-temperature shape keeping heat insulation nano-material and preparation method thereof

A nano-insulation material and dimensional technology, applied in the direction of layered products, etc., can solve the problems of reducing the heat sealing performance of the material, increasing the linear shrinkage, and decreasing the insulation performance of the material, so as to improve the high temperature dimensional stability and improve the maximum use. temperature, the effect of eliminating powder and slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

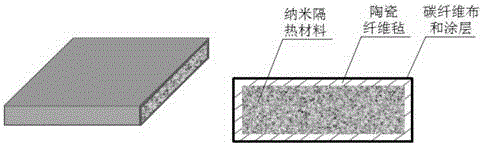

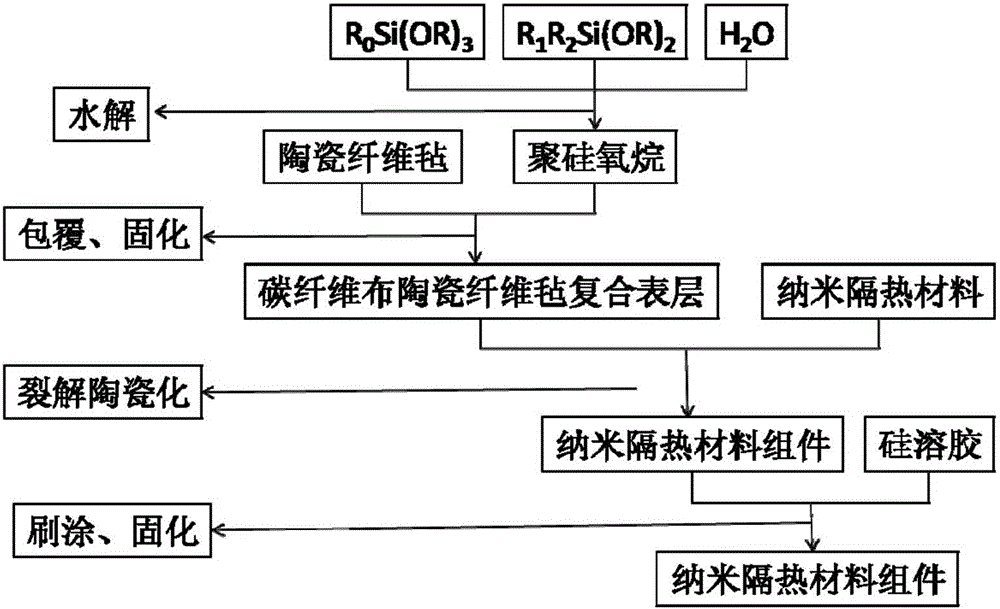

[0036] Such as figure 1 Shown is the flow chart of the preparation process of the high-temperature dimensional nano-insulation material of the present invention. The preparation method of the high-temperature dimensional nano-insulation material of the present invention specifically includes the following steps:

[0037] (1) Paste a ceramic fiber felt on one side of the carbon fiber cloth, the thickness of the ceramic fiber felt is 3-10mm.

[0038] The ceramic fiber felt is pasted on one side surface of the carbon fiber cloth by polysiloxane, and the polysiloxane is made of R 0 Si(OR) 3 and R 1 R 2 Si(OR) 2 Mixed and hydrolyzed to get, where R 0 , R 1 , R 2 for -CH 3 、-C 2 h 5 、-CH 2 =CH or -C 6 h 5 , R 1 and R 2 A group in can also be -H, R is -CH 3 、-C 2 h 5 or -C 4 h 9 , the R 0 Si(OR) 3 with R 1 R 2 Si(OR) 2 The mole fraction ratio is 1:0~0.25.

[0039] (2) Wrap the carbon fiber cloth with a ceramic fiber felt on one side of the surface on the sur...

Embodiment 1

[0043] (1) Preparation of polysiloxane binder: first, 272.0g CH 3 Si(OCH 3 ) 3 , 53.0gHCH 3 Si(OCH 3 ) 2 and 126.7g H 2 O mixed and stirred for 6 hours to obtain a polysiloxane solution; then, the polysiloxane solution was heated to volatilize the solvent, and the viscosity of the solution gradually increased until the solution mass was 45% of the initial solution mass to obtain a polysiloxane binder.

[0044] (2) Coat the surface of one side of the carbon fiber cloth with an adhesive, paste an alumina fiber felt with a thickness of 3 mm on the surface of the carbon fiber cloth, and cut it into a suitable size according to the size of the nano-insulation material.

[0045] (3) Wrap the carbon fiber cloth with alumina fiber felt on one side of the surface in step (2) on the surface of the alumina nano heat insulation material, and the alumina fiber felt is in contact with the alumina nano heat insulation material.

[0046] (4) Brush the polysiloxane solution prepared in s...

Embodiment 2

[0050] (1) Preparation of polysiloxane binder: first, 204.0g CH 3 Si(OCH 3 ) 3 , 20.1gHCH 3 Si(OC 2 h 5 ) 2 and 75.2 g H 2 O mixed and stirred for 8 hours to hydrolyze the silane; polysiloxane solution was obtained; then, the polysiloxane solution was heated to volatilize the solvent, and the solution viscosity gradually increased until the solution mass was 55% of the initial solution mass to obtain polysiloxane binder.

[0051] (2) Coat the surface of one side of the carbon fiber cloth with adhesive, paste the zirconia fiber felt with a thickness of 5 mm on the surface of the carbon fiber cloth, and cut it into a suitable size according to the size of the nano-insulation material.

[0052] (3) Wrap the carbon fiber cloth with zirconia fiber felt on one side of the surface in step (2) on the surface of the alumina nano heat insulation material and contact the zirconia fiber felt with the alumina nano heat insulation material.

[0053] (4) Brush the polysiloxane soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com