Method for manufacturing tissue-engineered vascularized liver lobules

A manufacturing method and tissue engineering technology, applied in the field of biomedicine, can solve problems such as poor precision, time-consuming and labor-intensive, structures that cannot be processed, and achieve good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific embodiments.

[0018] The manufacturing method of the tissue engineered vascularized liver lobules in this embodiment comprises the following steps:

[0019] Step 1, print the supportive PDMS frame of the liver lobules and make the mold of the liver lobules. The specific process is as follows:

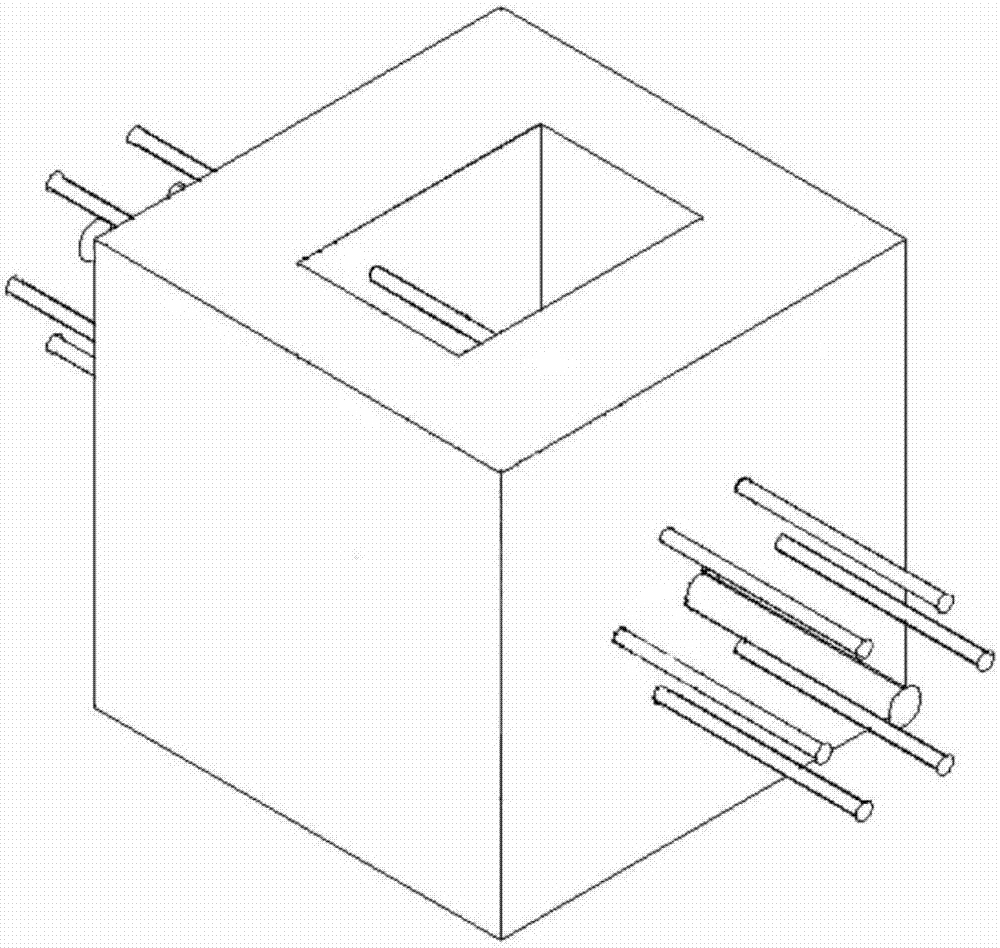

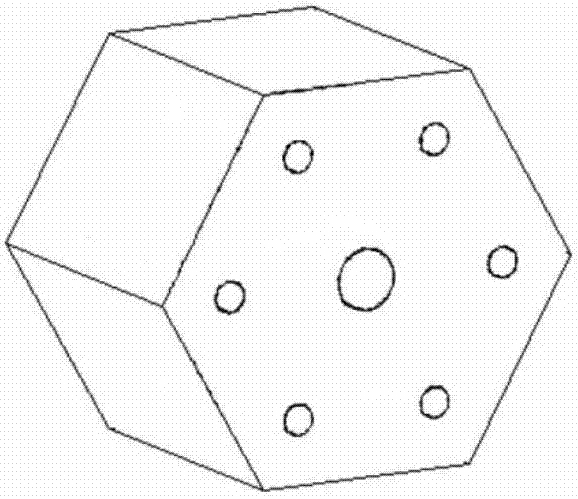

[0020] The supporting frame is printed using polydimethylsiloxane (PDMS). Mix PDMS evenly according to the mass ratio of substrate and cross-linking agent at 10:1, add it into the syringe of the 3D printer, and print out the PDMS frame according to the set path. Insert seven capillary glass tubes into the PDMS frame, which constitutes the forming mold of the liver lobule, such as figure 1 shown. It is used after being sterilized by high temperature and high pressure.

[0021] Step 2: Mix the HepG2 cells with the temperature-sensitive hydrogel solution according to the cell concentration of 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com