Silver-white metal zipper and manufacturing method thereof

A technology of a metal zipper and a manufacturing method, which is applied in the direction of metal material coating process, clothing, fasteners, etc., can solve the problems such as easy oxidation of aluminum alloy tooth zipper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

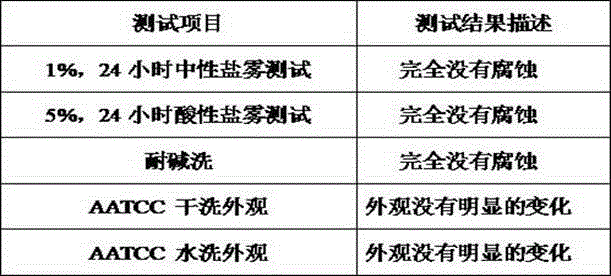

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with embodiment.

[0022] The silver-white metal zipper of the present invention includes aluminum alloy teeth and a silver-white oxide layer on the surface of the teeth. The oxide layer is deposited on the surface of the teeth to make the teeth resistant to oxidation and corrosion, and has a silvery white metallic luster. In this embodiment, the tooth material is aluminum alloy, including the following components in weight percentage: Si: 0.1-0.2, Mg: 0.4-0.5, and the balance is aluminum. In this embodiment, an epoxy resin protective layer is coated on the oxide layer of the metal zipper, and the thickness of the epoxy resin protective layer is 0.05-0.30 mm, so as to further prevent the teeth from oxidative discoloration.

[0023] The manufacture method of silver-white metal zipper of the present invention comprises the following steps:

[0024] A: Use a grinder to mechanically polish the teeth of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com