Method for preparing composite active material bipolar electrode for bipolar lead-acid battery

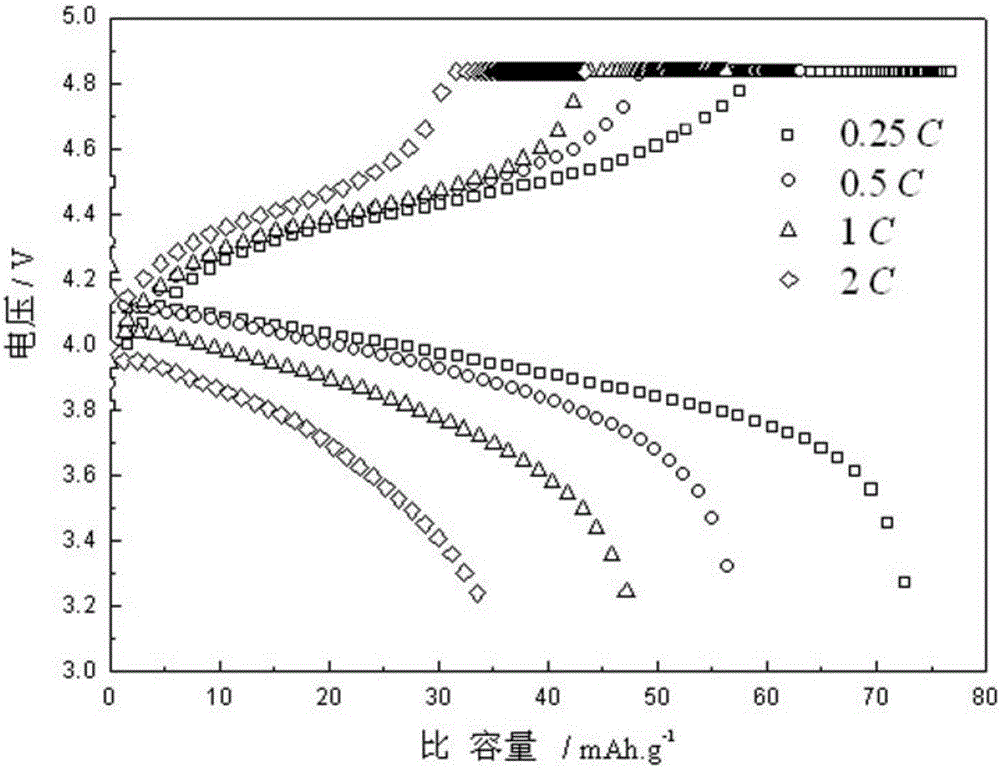

A composite active material and bipolar electrode technology, which is applied to lead-acid battery electrodes, batteries with bipolar electrodes, lead-acid batteries, etc., can solve the problems of affecting electron conduction in active materials and reducing the conductivity of lead paste , to achieve the effect of improving the specific capacity and cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

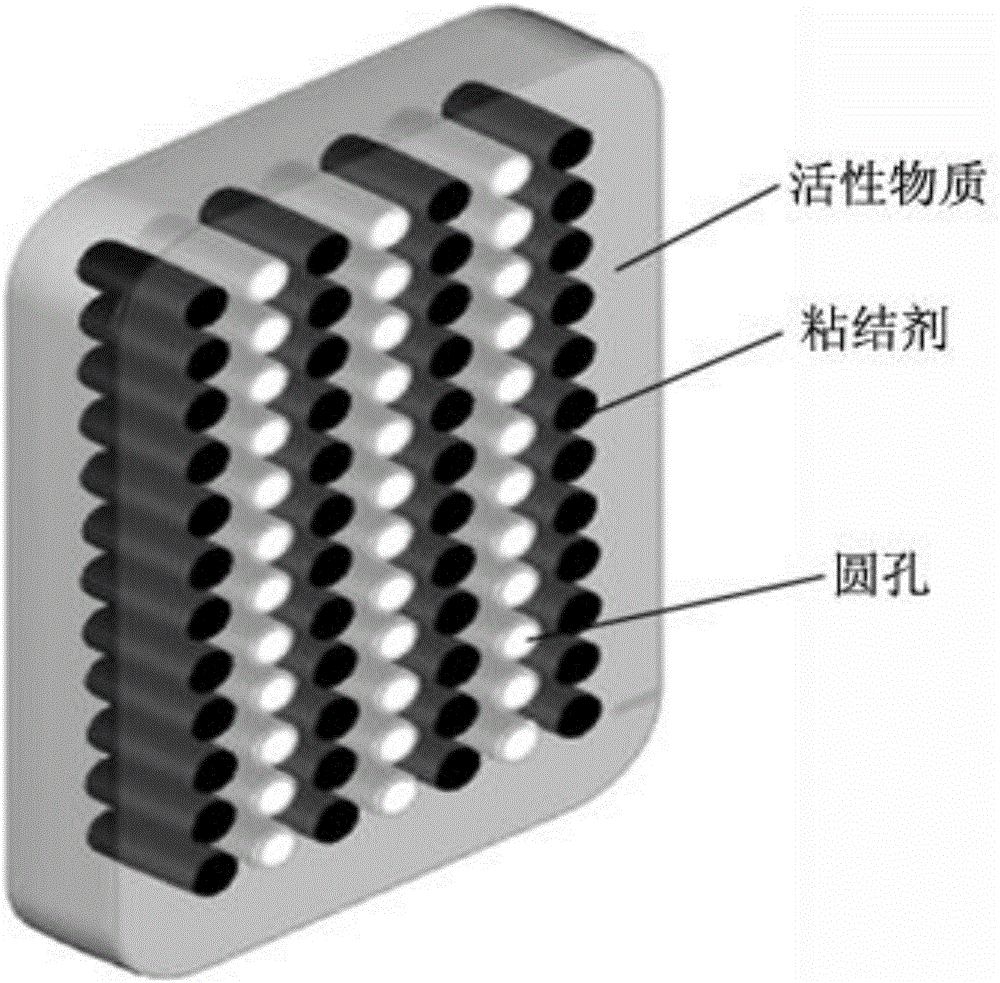

[0026] 1.1. Coat the plate active material lead paste on the surface of the substrate. The coating thickness of the active material is 1.5mm. Then, evenly and vertically open multiple rows of circular holes on the active material. The diameter of the circular holes is 1mm. The distance between the two round holes is 2mm, and the depth of the round holes is the same as the thickness of the active material coating;

[0027] 1.2, such as figure 1 As shown, some of the circular holes are filled with graphite / PTFE emulsion conductive adhesive and filled, and the circular holes with binder account for 60% of the total number of circular holes; the remaining 40% of the circular holes are left without any treatment to provide for the diffusion of electrolyte. Passage, obtains polar plate, and the mass ratio of PTFE emulsion (60wt%) and graphite is 7:1 in the described graphite / PTFE emulsion conductive adhesive;

[0028] 1.3. Curing the plate obtained in step 1.2 under constant temper...

Embodiment 2

[0034] 1.1. Coat the lead paste of the active material of the plate on the surface of the substrate. The coating thickness of the active material is 3.5mm. Then, evenly and vertically open multiple rows of round holes on the active material. The distance between the two round holes is 3mm, and the depth of the round holes is the same as the thickness of the active material coating;

[0035] 1.2, such as figure 1 As shown, the graphite / PTFE emulsion conductive adhesive is filled in some of the circular holes and filled, the circular holes added with adhesive account for 20% of the total number of circular holes; the remaining 80% of the circular holes do not do any treatment, providing for the diffusion of electrolyte Passage, obtains polar plate, and the mass ratio of PTFE emulsion (40wt%) and graphite in described graphite / PTFE emulsion conductive adhesive is 9:1;

[0036] 1.3. Curing the plate obtained in step 1.2 under constant temperature and humidity conditions. The sta...

Embodiment 3

[0038] 1.1. Coat the lead paste of the active material of the plate on the surface of the substrate. The coating thickness of the active material is 2mm. Then, evenly and vertically open multiple rows of round holes on the active material. The distance between each circular hole is 2.5mm, and the depth of the circular hole is the same as the thickness of the active material coating;

[0039] 1.2, such asfigure 1 As shown, some circular holes are filled with graphite / PTFE emulsion conductive adhesive and filled up. The circular holes with binder account for 40% of the total circular holes. Passage, obtains pole plate, and the mass ratio of PTFE emulsion (20wt%) and graphite is 5:1 in the described graphite / PTFE emulsion conductive binder;

[0040] 1.3. Curing the plate obtained in step 1.2 under constant temperature and humidity conditions. The staged curing process is adopted, that is, first curing at 50°C and 90% humidity for 36 hours, then curing at 65°C and 60% humidity fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com