Explosion-proof directional pressure-relief type battery box and preparation method thereof

A battery box and pressure relief technology, which is applied in the direction of battery box/jacket, battery, battery pack parts, etc., can solve the problems that the battery box does not have a protective effect, the lithium battery explodes, and endangers the life safety of passengers, etc., to achieve Good explosion-proof effect, weight reduction, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

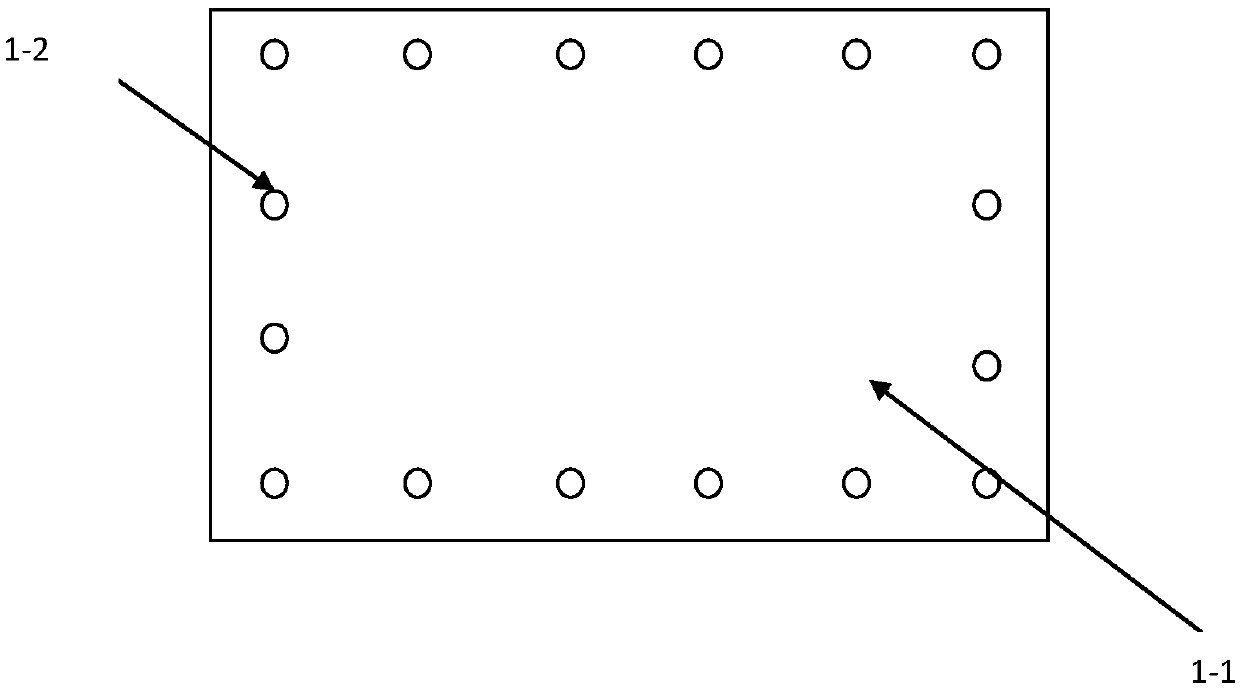

[0032] In this embodiment, a battery box placed at the bottom of a car is taken as an example for illustration.

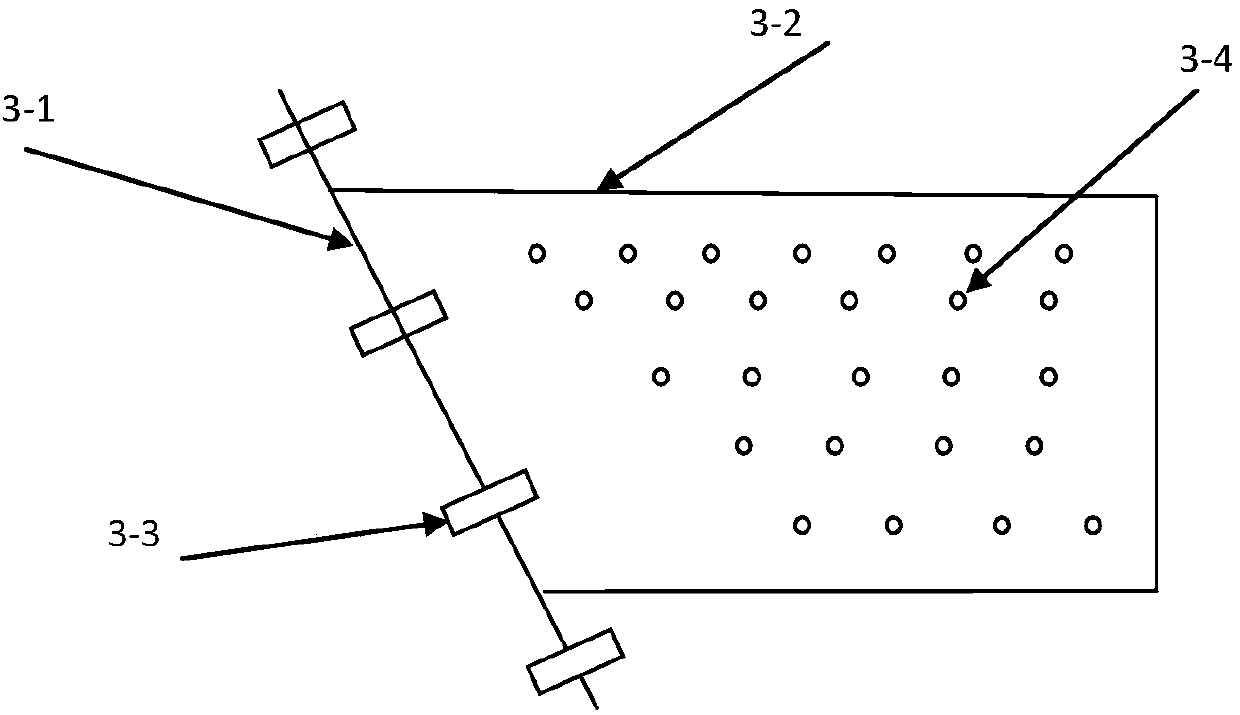

[0033] 1. Preparation of battery box body

[0034] A polyethylene box is selected as the core mold of the box body. There are holes distributed around the core mold. The diameter of the hole is 1mm, and the short tube passes through the hole. The short tube exceeds the surface of the box body by 5mm. The 12K high modulus poly The vinyl fiber is evenly wrapped around the short tube outside the polyethylene mandrel for one layer, and then the 12k carbon fiber impregnated with epoxy resin is evenly wrapped around the short tube for two layers on the outer layer. The total thickness of the fiber after winding is 2mm. Put the box in an oven at 120°C to cure the epoxy resin. After curing, pull out the short tube to get a box reinforced by high modulus polyethylene and carbon fiber winding. There are 1mm holes around the box for heat dissipation and drainage. Wire. Dril...

Embodiment 2

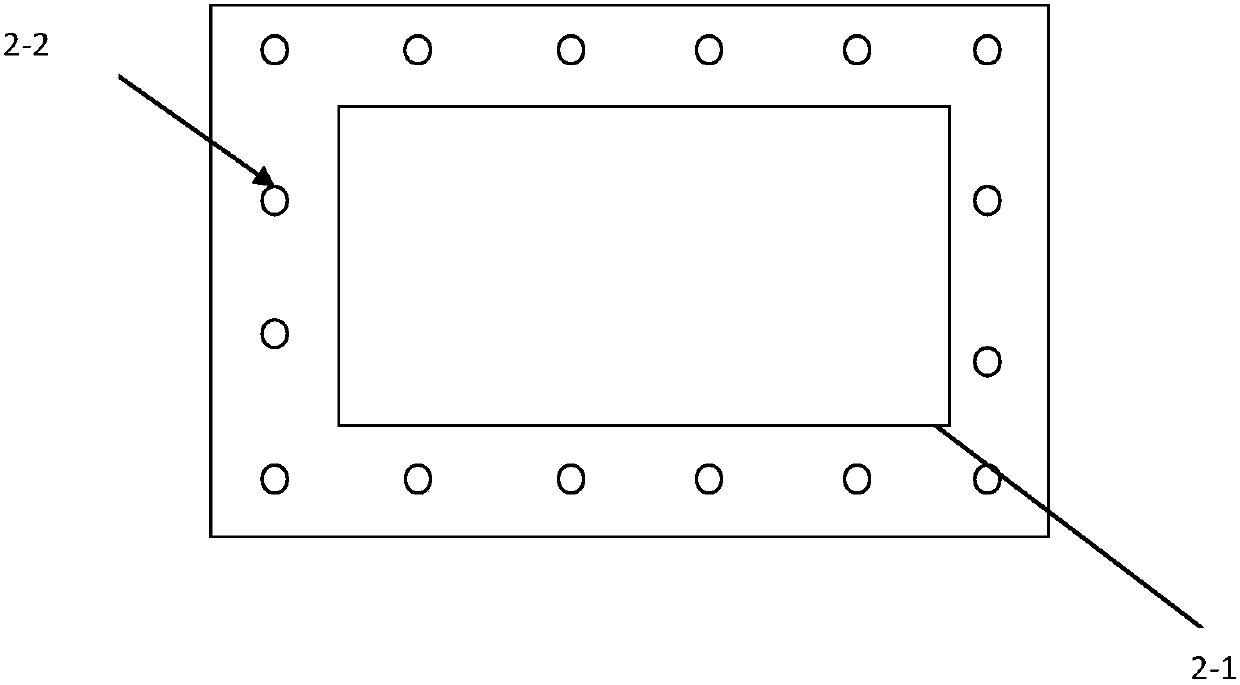

[0041] In this embodiment, a battery box placed on the roof of a car is taken as an example for illustration.

[0042] 1. Preparation of battery box body

[0043]The aluminum box is selected as the core mold of the box body. There are holes distributed around the core mold. The diameter of the hole is 2mm, and the short tube passes through the hole. The short tube exceeds the surface of the box body by 5mm. The 12k high-strength glass fiber impregnated with vinyl resin The mandrel is evenly wound around the short tube for 4 layers. After winding, the total thickness of the fiber is 3mm, and then the box is irradiated to cure the matrix. After curing, the short tube is pulled out to obtain a high-strength glass fiber-reinforced box. There are 2mm holes around it for heat dissipation and wiring. Drill holes in the contact part of the box cover to allow the bolts to pass through.

[0044] 2. Preparation of the lid

[0045] Choose an aluminum plate as the mandrel of the box cov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com