Power module integrated with radiator

An integrated heat sink and power module technology, applied in the direction of electric solid-state devices, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of large thermal resistance, performance degradation, and low thermal conductivity from the chip to the heat sink, and achieve Effects of reducing heat transfer paths, improving reliability, and simplifying structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution is described in detail below by a preferred embodiment in conjunction with the accompanying drawings:

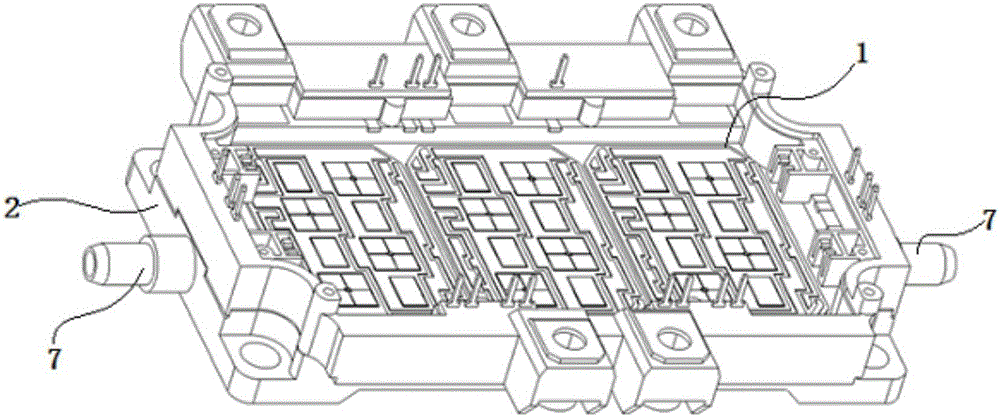

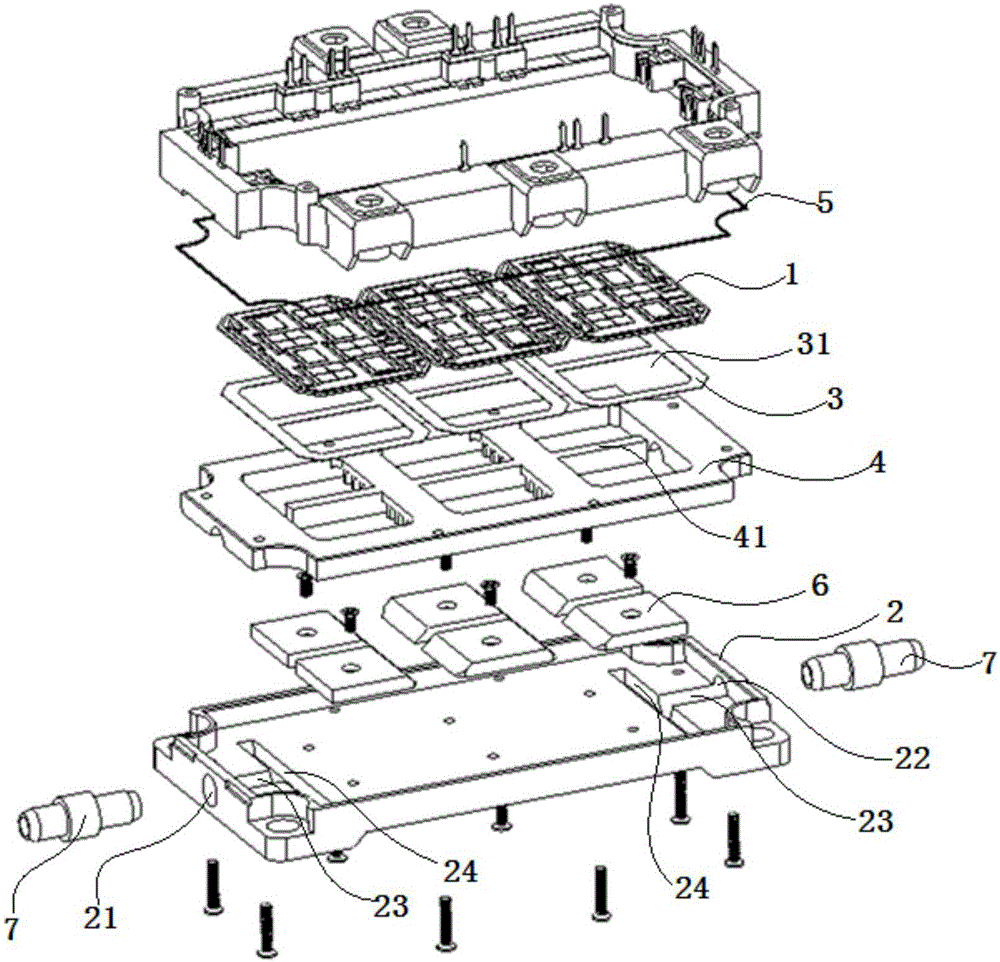

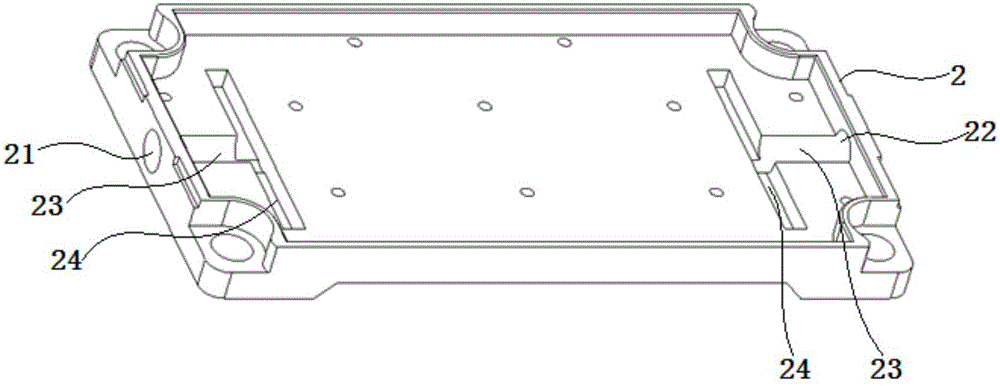

[0025] Such as figure 1 , figure 2 As shown, a power module with an integrated heat sink includes an insulating substrate 1. Since the heat dissipation device is integrated in the power module of the present invention, the insulating substrate 1 is easily deformed due to the pressure of the heat dissipation medium under the insulating substrate 1 of the power module during use. and weld fatigue. In order to avoid deformation of the insulating substrate 1 and premature fatigue failure of the welding layer 3, the insulating ceramic layer in the insulating substrate 1 is preferably Al with a thickness of 0.63mm or more. 2 o 3 , or AlN, or Si 3 N 4 , and for a large-area insulating substrate 1, it is recommended that the insulating substrate 1 be welded in different regions, that is, the shunt plate 4 is provided with more shunt beams 41; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com