Steam turbine generator provided with axial-radial ventilating and cooling system

A steam turbine generator, ventilation and cooling technology, applied in cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve the problems of motor temperature rise, affecting the safe and stable operation of the motor, etc., to increase the total cooling area, reduce Heat transfer path, the effect of improving the heat dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

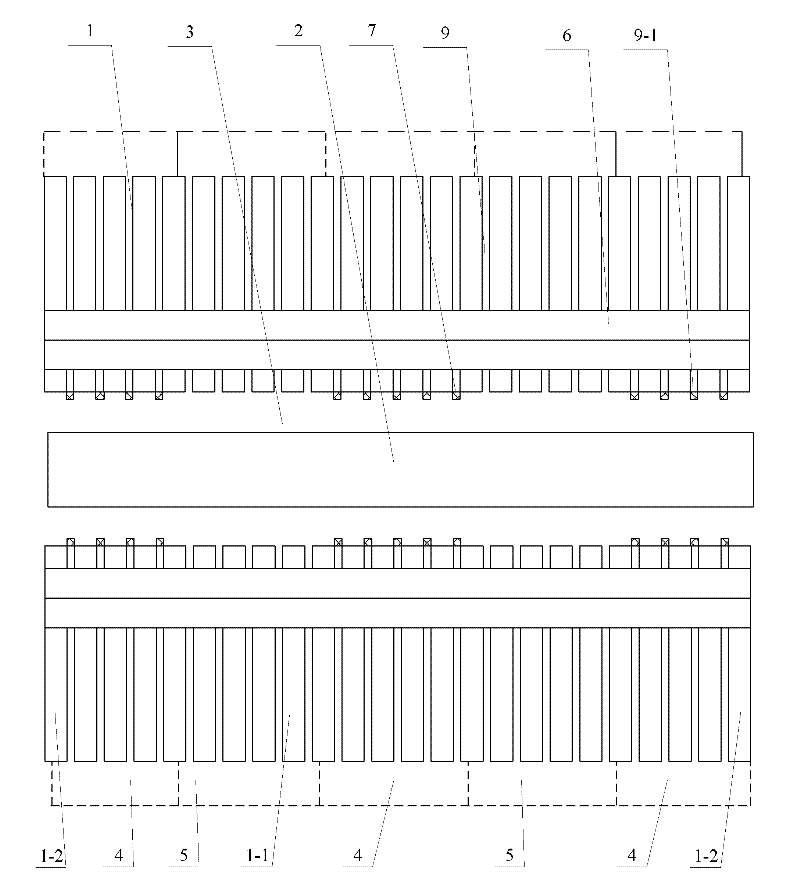

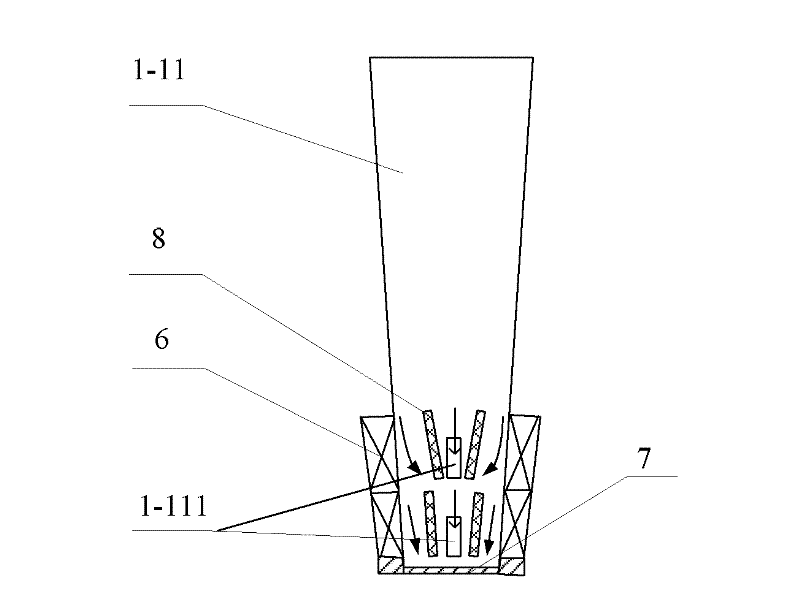

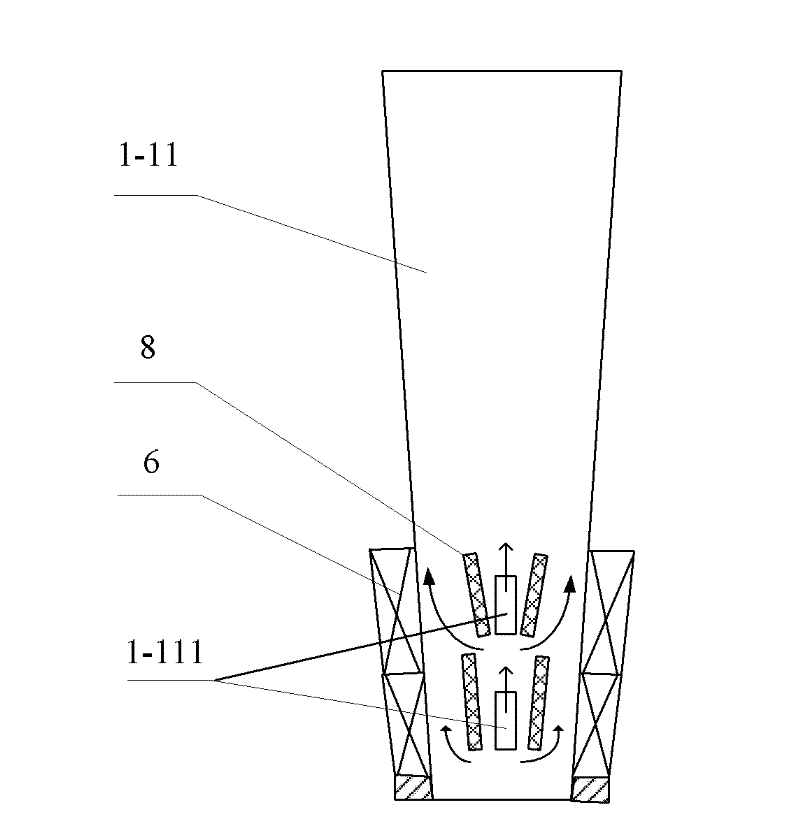

[0017] Specific implementation mode one: the following combination Figure 1 to Figure 5 This embodiment is described. This embodiment includes a stator 1 and a rotor 2. There is an air gap 3 between the inner circular surface of the stator 1 and the outer circular surface of the rotor 2. The stator 1 is composed of multi-stage stator cores arranged at equal intervals. The multi-stage The stator cores are arranged axially along the rotor 2, and the two segments of the stator cores located at both ends are the end stator cores 1-2, and the rest of the stator cores are the middle stator cores 1-1. To the ventilation ditch 9, the stator 1 is provided with a plurality of cold wind zones 4 and a plurality of hot wind zones 5 in the axial direction, the multiple cold wind zones 4 and the multiple hot wind zones 5 are arranged alternately, and the two ends of the stator 1 are In the cold wind area 4, the stator winding 6 is wound on the stator 1, and the inner surface of each stator ...

specific Embodiment approach 2

[0027] Specific implementation mode two: the following combination figure 2 with image 3 This embodiment is described. This embodiment is a further description of Embodiment 1. The axial air hole 1-111 is arranged at the center position of the stator tooth 1-11 along the circumferential direction. Others are the same as the first embodiment.

[0028] The installation positions of the axial air holes 1-111 in this embodiment can ensure the balance of heat dissipation capability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com